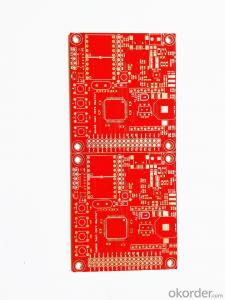

High quality 2 layer flex pcb, UL approved

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Product Description

1. UL,ISO9001,ISO14001, TS16949 certificate

2. Short lead time.

3. PCB ROHS compliant.

4. Turkey service

Free Technology Support

PCB Assembly

Turnkey service(PCB manufacture, components procurement and assembly)

Minimum lead time for assembly is only 5 days

Prototype building, No Minimum quantity Required

Reliable Parts

Surface mount, through hole, BGA, QFP, QFN …

ROHS compliant and lead-free process

PCB Capability

Material: FR4, CEM-3, Halogen Free, Rogers, High TG etc.

Layer counts: 1-18 layers

Finished Copper Thickness: 0.5-4 OZ

Finished Board Thickness: 0.2-5.0mm

Min. Line/Track Width: 4mil

Min. Line/Track Space: 4mil

Min. Contour Tolerance: +/-0.1mm

Min. Finished Diameter of PTH Hole: 0.2mm

Max. Board Thickness/Hole Ratio: 12:1

Min. Solder Mask Bridge: 4mil (Min. SMT Pad Space 8mil)

Min. Legend (Silk screen) Track Width: 5mil

Min. Legend (Silk screen) Height: 30mil

Min. drilling slot size: 0.6mm

Solder mask color: green, black, blue, white, yellow, purple, and matt, etc.

Legend/Silk screen Color: white, yellow, black, etc.

Surface Treatment: HAL, Lead Free HAL, Immersion gold, OSP, Immersion tin, Immersion silver, etc.

Other Technology: Gold finger, peelable mask, Non-across blind/buried vias, characteristic impedance control, Rigid-flex board etc.

Reliability Test: flying probe test/fixture test, impedance test, solderability test, thermal shock test, hole resistance test, and micro metallographic section analysis, etc.

Bow and twist: ≤1%

Flammability: 94V-0

4. Professional engineering staff to provide technical support.

5.OEM and ODM service are welcome.

Packaging Detail: Vacuum packaging

Delivery Time: 10-15 days

- Q:What is the difference between PCB and FPC?

- With the product now light, thin, short, small development, some products PCB is not very good to meet the requirements, will gradually use FPC to achieve. In short, FPC can be understood as a soft, flexible PCB

- Q:What is the difference between FPC PCB PCBA PCBI?

- PCBA is the English Printed Circuit Board + Assembly referred to, that is, after the PCB board empty pieces, and then through the DIP plug-in the entire process, referred to as PCBA.

- Q:Can a small capacity capacitor on a circuit board be replaced with a lot more

- It is best not to do so, the capacity is not the same resistance value is not the same. Through the frequency is not the same. You change it in the circuit current or voltage frequency and so on, affecting the whole. Generally replaced by the original capacity is the best.

- Q:Fpc process specific what is

- Prenatal pretreatment, need to deal with three aspects, these three aspects are completed by the engineers. The first is the FPC board project evaluation, mainly to assess whether the customer's FPC board can produce, the company's production capacity can meet the customer's board requirements and unit costs; if the project assessment through, then you need to immediately prepare, to meet the various production processes Finally, the engineers:

- Q:How parts are soldered on the circuit board

- the method: the interface to deal with clean, the line connected to the corresponding location of the circuit board, electric iron stained with solder, dipped in the rosin fast point in the interface position, pay attention to the time not too long, if one did not remember To cool down in the re-processing, or will burn the circuit board.

- Q:FPC tube and PVC pipe is different

- The difference between the two is different plastic pipe, FPC is a semi-rigid plastic pipe, PVC is generally rigid plastic pipe.

- Q:What are the FPC flexible printed circuit board materials?

- The effect of the adhesive sheet is to bond the film with a metal foil, or bond the film with a film (cover film). Different types of adhesive films can be used for different film substrates, such as polyester adhesive sheet and polyimide adhesive sheet is not the same,

- Q:How the board surface is insulated

- Circuit board can be called printed circuit board or printed circuit board, the English name for (Printed Circuit Board) PCB, (Flexible Printed Circuit board) FPC circuit board [1] (FPC circuit board, also known as flexible circuit board flexible circuit board is poly Imide or polyester film made of a substrate with a high degree of reliability, excellent flexible printed circuit board with a high wiring density,

- Q:Circuit board of the green skin and silver contacts were burned iron, but also use it?

- Circuit board can be called printed circuit board or printed circuit board, the English name for (Printed Circuit Board) PCB, (Flexible Printed Circuit board) FPC circuit board [1] (FPC circuit board, also known as flexible circuit board flexible circuit board is poly Imide or polyester film made of a substrate with a high degree of reliability,

- Q:What is the difference between PCB and FBC?

- The culture method of the fresh medium is a transitional culture between batch fermentation and continuous fermentation. The PCB is a circuit board, is dedicated to the production of circuit boards. You should be wrong, these two categories are different.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

High quality 2 layer flex pcb, UL approved

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products