Packaging & Delivery

| Packaging Details: | 400 pcs/ bundle |

|---|---|

| Delivery Detail: | 15 days |

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

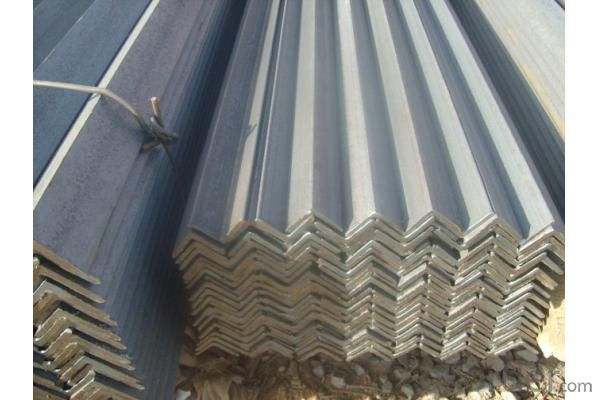

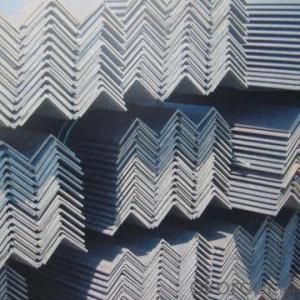

Standard:GB, JIS

Dimensions:20*0.8-20*3

Grade:Q195-Q420 Series

Place of Origin:Hebei, China (Mainland)

Brand Name:DH

Model Number:2.5#

Type:Equal

Application:building

| Packaging Details: | 400 pcs/ bundle |

|---|---|

| Delivery Detail: | 15 days |

Q235 SS400 hot rolled

20*0.8-200*25

high quality low price and good service

specifications: 20mm*20mm*0.8mm -20mm*20mm*3mm

2.5mm*25mm*0.8mm- 25mm*25mm*3mm

30mm*30mm*0.8mm -30mm*30mm*4mm

3.5mm*35mm*0.8mm- 35mm*35mm*4mm

38mm*38mm*0.8mm -38mm*38mm*4mm

40mm*40mm*0.8mm -40mm*40mm*5mm

50mm*50mm*0.8mm -50mm*50mm*5mm

length: 5.5m 5.8m 6m 9m 12m

our advantage: 1. thickness can be 0.8mm

2. bottom price

3.reliable quality and service

4. fast delivery

grade:Q235 , Q345, SS400

package: in bundle, fasten by wire rod with tags or according to customers' requirements.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords