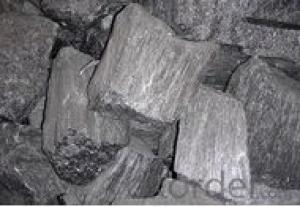

High Purity Fused Mullite For Refractory

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

Fused Mullite :

1,high purity fused mullite

2,provide mullite with different grades and size

Description:

Mullite is a raw material with high heat resistance. At present, there are mainly high purity fused mullite, ordinary fused mullite, finely sintered mullite with all natural bauxite and caustic-burned mullite.

Mullite of Ruishi Brand is made of high quality pure natural mullite ore, melted from the advanced industrial furnace with high temperature. It is featured by uniform expansion, excellent thermal shock resistance, high softening point with load, low elevated temperature creep value, high hardness, good resistance to chemical corrosion etc.

Specification:

Mullite:

Specification | Item | Chemical composition(%) | ||

Al2O3 | Si02 | Zr02 | ||

AS-Ⅰ AS-Ⅱ AS-Ⅲ | Sintered | 42-47 56-67 70-76 | 51-55 28-42 23-28 | --- --- --- |

AS-I AS-Ⅱ | Fused | 60-70 70-77 | 25-35 22-29 | -- -- |

Particle size :0-1mm/1-3mm/3-5mm/5-8mm;180mesh-0/320mesh-0

Packing: 1 MT big bag or 25kg paper bag *40 bags on one pallet ;

As per customer’s requirement

Advantages:

1.expansion uniformity

2.excellent thermal shock resistance

3.high load softening point

4.small high temperature creep value

5.high hardness

6.good resistance to chemical corrosion

FACTORY:

- Q:What's the maximum temperature that the refractory ceramic fiber cloth can endure?

- While the refractory ceramic fiber cloth is different in high temperature resistance, and in general it can endure the high temperature of more than 1000℃. Ceramics in daily use and art ceramics: Bone china and Guangdong chinaware can generally endure the highest temperature of 1100℃. Jingdezhen porcelain and ceramics: They can generally endure the highest temperature of 1280℃-1340℃, and some special ones can endure the highest temperature of 1400℃. Industrial ceramics: Some of them can endure the highest temperature of about 2600℃. (alumina ceramics: their melting point is 2050℃, and boiling point is 3000℃).

- Q:What is shapeless refractory with high performance?

- The popular ones are: Non-cement fine powder bonded castable is a functional refractory castable with nano material introduced.

- Q:Which refractory material is better in China? Industrial furnace, mainly in non-ferrous industries, glass kiln, cement kiln business.

- Such solid nano microporous insulation material with nano inorganic refractory powder special, with a huge surface area, nano particles contact between the minimum point contact point contact thermal resistance is very large, the heat conduction effect of the material becomes very small, resulting in heat conduction coefficient of solid such nano porous insulation materials very small; nano pores formed of nanoparticles, the average size of 20 nm, and the average free path of molecular thermal motion at room temperature under static air is 60 nm, thus locking the air molecules in powder within nano pores, making the micro convection heat transfer effect between the stationary air molecules disappeared. The room temperature thermal conductivity of solid such nano microporous insulation material is lower than the static air; at high temperature, the main effect of heat transfer heat radiation, Good energy-saving insulation materials with nano microporous infrared additive special, stop at a high temperature and reflected infrared radiation, reduce the heat radiation effect to the lowest point, the radiation heat transfer coefficient of materials under high temperature is reduced to the lowest value.

- Q:Who knows about the fire endurance of A grade fireproofing glass doors?

- The fire endurance of grade A fire resistance rolling shutter doors should be no less than three hours. Fire doors can be divided into A, B and C grades according to their fire endurance which should be no less than 1.20 h, 0.90 h and 0.60h respectively. Places where are difficult to set fire-proof bulkheads can use fire resisting shutters as partitions of fire?compartments. The fire endurance of fire resisting shutters that include unexposed surface temperature rise as judging condition should be no less than 3 h. Fire resisting shutters that exclude unexposed surface temperature rise as judging condition should set up independent protection of closed automatic water spray system on both sides of shutters, and the duration of water spray system should be no less than 3.0 h.

- Q:Who knows about the differences between 3M fireproofing materials and ShiLiDe materials?

- Advertising materials can be divided into fireproofing and non-fireproofing ones which can not tell the differences with naked eyes. You can ask 3M to provide test reports or go to a the third party test organization SGS to do flame retardant test, maybe I can help you. Mineral wool board is harmful to human body, will lead to chronic poisoning, the quality of it is bad! You must pay attention to it! It can not be used in chemical and pharmaceutical plants.

- Q:Fire resistance and evaluation of refractory for casting

- The products to be tested are broken and ground, adding organic binders (usually dextrin) that do not affect the refractoriness. Water is used to make standard sized test cones, as shown in figure 1-2-1. Test cone is positive, three edge cone, the bottom side length of 8.5mm, the top side length is 2mm.Test, the equivalent of high standard cone refractoriness of the 2 products to be high, No. 1 and No. 1 high temperature low standard cone of each one, and the 2 to be tested in accordance with regulations frustum cone plug made of high aluminum material, a cone prism and vertical 8 degrees. 1 degrees tilt angle. Then, the cone is heated in a high temperature furnace. When the test cone with a high temperature and bending down to the standard cone top contact cone, the high standard cone refractoriness refractoriness is running.

- Q:Why the corundum can be used as refractory

- Corundum has high refractoriness, so its high temperature performance is very good.

- Q:Who can introduce the external wall thermal insulation materials fire rating regulations?

- 1. The thermal insulation material of level A combustion performance: Rock wool, glass wool, foam glass, foamed ceramics, foam cement, hole-closed perlite, etc. 2. combustion performance is level B1 insulation materials: Extruded polystyrene board (XPS) after special treatment / Special treatment of polyurethane (PU), phenolic aldehyde and gelatine powder polyphenyl granule 3 combustion performance is level B2 insulation material: Molding polystyrene board (EPS), extruded polystyrene board (XPS), polyurethane (PU), polyethylene (PE), etc. See the 2009 edition construction technical measures 4.3.6 Level A insulation material is only for fireproofing, but its thermal insulation performance is not better than organic XPS \\ EPS and other materials. I feel the best insulation materials should be modified phenolic board, which can keep insulation and fireproofing, but the unit price is very expensive. Insulation materials in the domestic market have some disadvantages, it is better to considere the materials within the acceptable range in the building needs.

- Q:Can anyone tell me which materials are fire-proof high temperature resistant material?

- Fireproof high temperature resistant material is the synthetic material with fireproofing properties, or the material itself is high temperature resistant, heat-resistant, flame-retardant material. Fireproof materials are mainly used for construction with a variety of forms, which plays an absolute role in modern fire protection. The commonly used fireproof materials including fireproof panels, fire doors, fireproof glass, fire retardant coating and fireproof bag, etc.

- Q:What is the the best ratio of mortar in refractory cement?

- The ratio of refractory cement are: M10 the ratio of cement and mortar: cement: Sand= 346kg: 1631kg M7.5 ratio of cement and mortar: cement: Sand =274kg: 1631kg M5 The mix proportion of cement and mortar: cement: Sand = 209kg: 1631kg M10 mix proportion of composite mortar: cement: Sand: Lime =306kg: 1600kg: 29kg M7.5 mix proportion of composite mortar: cement: Sand: Lime =216kg: 1600kg: 64kg M5 The mix proportion of composite mortar: cement: Sand: Lime =205kg: 1600kg: 100kg

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

High Purity Fused Mullite For Refractory

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords