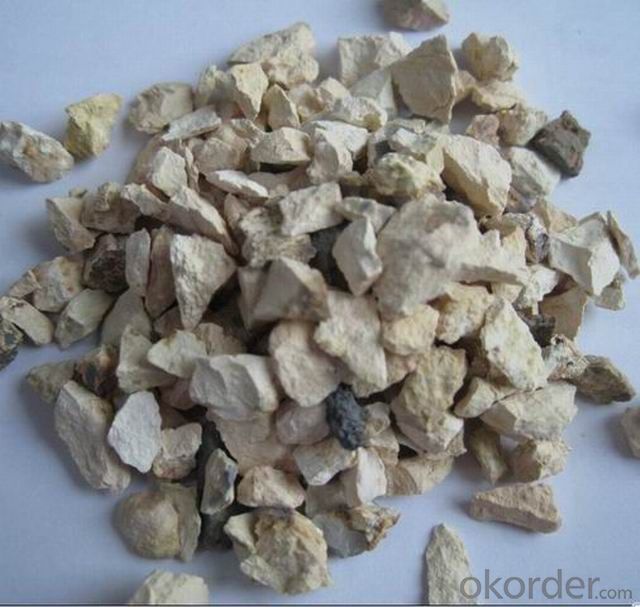

High Purity Calcined Bauxite Powder Supplied by CNBM

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

Calcined bauxite is one of the principal ore of aluminum. Calcined bauxite contains hydrous aluminum oxides and aluminum hydroxides, formed through the laterization of aluminous rocks in tropical and subtropical areas .calcined bauxite is obtained by calcining (heating)superior grade bauxite at high temperature (from 85OC to 1600C) .this removes moisture thereby increasing the alumina content. compared to an alumina content of about 57%to 58%in raw bauxite, calcined bauxite has an alumina content of 84%to88%.the heating is carried out in rotary kilns.

Applications

calcined bauxite is typically calssified according to its intended commercial application,such as abrasive ,cement ,chemical, metallurgical, and refractory .as raw material for use in high alumina and super duty refratory bricks and shapes ,plastics ,castable refratory, motors, gun mixes, ramming mixes, abrasive grains and other products

Chemical Specification:

Rotary Kiln Calcined Bauxite

Grade | AL2O3 | FE2O3 | TIO2 | K2O+Na2O | CaO+MgO | Bulk density |

75 | 75min | ≤3.0 | ≤4.0 | ≤0.3 | ≤0.5 | ≥2.70 |

80 | 80min | ≤3.0 | ≤4.0 | ≤0.3 | ≤0.5 | ≥2.80 |

85 | 85min | ≤2 | ≤4.0 | ≤0.3 | ≤0.5 | ≥3.00 |

86 | 86min | ≤2 | ≤4.0 | ≤0.3 | ≤0.5 | ≥3.10 |

87 | 87min | ≤2 | ≤4.0 | ≤0.3 | ≤0.5 | ≥3.20 |

88 | 88min | ≤1.8 | ≤4.0 | ≤0.25 | ≤0.5 | ≥3.25 |

90 | 90min | ≤1.8 | ≤4.0 | ≤0.25 | ≤0.5 | ≥3.30 |

- Q:Which brand of refractory fiber hard thermal insulation board is better?

- One colleague said Huayou refractory fiber hard thermal insulation board is good. The size (mm): 600*400*60. refractory temperature: 1770 ~ 2000 ℃ (℃), and the price is 2850 yuan a ton.

- Q:what is the original materials of fireproof coating?

- Fire retardant coating is composed of the base materials (that is film forming substance), pigments, ordinary coating additives, fire retardant agent and dispersion medium. In addition to fire retardant agent, other components functions the same as in ordinary coating, but its performance and thickness are specifically required. Some solvent-based fire retardant coating can burn upon encountering fire before construction.In fact,It is the flammable solvent contained in the coating that is burning while substances such as the base materials and fire retardant agent does not burn. Because solvent-based fireproof coating contains organic solvent and these fire-resistant coating, once leaked from the bucket, are likely to cause a fire. Fireproof coating on the substrate can insulate heat only after the solvent contained evaporates compeletly.

- Q:What are the features of construction class A fire resistant door ?

- 1, Save space and reduce cost. Feature of Nanjing Cathay Class A external wall thermal insulation materials : the thickness is between 60mm--180mm, so compared with the traditional block thickness, it saves architectural space greatly. At the same time, the weight is only 1/10 of that of the traditional wall, thus reducing coast in terms of architectural?structure. 2, Fireproof and green. Features of Nanjing Cathay class A fireproof external wall thermal insulation materials: fire endurance under high temperature of 1000℃ is 4 hours, and non-combustible performance can reach state A level, without any toxic gas in full compliance with international environmental standards. 3, Waterproof. Features of Nanjing Cathay Class A fireproof external wall thermal insulation materials: no slightest leakage when it is being used in containers for water without any waterproof finishing. It can be used in kitchens, bathrooms, basements and other wet areas. 4, Sound insulation. Features of Nanjing Cathay class A fireproof external wall thermal insulation materials: internal materials and EPS polystyrene foam granule have good properties of sound insulation and sound absorption. 90mm-thick wall can insulate 40dB sound, in line with national standard of sound insulation for residential building. 5, Thermal insulation. Features of Nanjing Cathay Class A fireproof external wall thermal insulation materials: main raw material is frezing resistant and thermal insulating material which is environmentally friendly and energy saving. With good effect of thermal insulation, it can keep indoor temperature at a constant level, so as to make the environment more comfortable.

- Q:What does fire-resistant insulation coating have?

- What is the most famous is that grade A is incombustible?thermal?insulation?material. W W inorganic active wall insulation materials, cement foam insulation board, vitrified?micro bead?thermal insulation?mortar, rock wool board, glass wool board, foam ceramics, etc.

- Q:Urgent question: could you tell me that the export of refractory materials to Vietnam is to be packed in wooden cases and smoked?

- Solid wood logs are necessary. If it is the type of smoke free material, it will not be necessary. You'd better confirm it with the port of destination. Vietnam has the requirement to smoke

- Q:who knows the technology of fireproofing material?

- First: Firstly, you should produce the recipe and prepare the raw materials, for example, if you prepare to produce 1 ton, you should compute the recipe sheet of 1 ton producing; check whether the raw materials are complete; second: make the color and filler thick liquid; add water in order and proper auxiliary in a low speed, then put color and filler (generally we should firstly add something with large oil absorption), wash the meachine after putting the powder. Then seperate them for about 20 miutes in a high speed, until the fineness is qualified; of course, if you need sander, i think you only need sino-soviet differential powder material and non-obvious particles. Third: Paint mixing period: after making the color and filler thick liquid, reduce the roll speed into about 600 roll per minute, add emulsion and proper auxiliary, finally adjust PH and viscosity. Liquid solvent paint, pigment paste: Resin,solvent and pigment ---〉pre mixing---〉stick---〉grinding--〉stick--〉packaging, highlight varnish: Resin, solvent ----〉mixing ----〉stick ----〉packaging, sub-gloss varnish: Resin, solvent----〉mixing----〉matting agent,stick----〉packaging, colored?paint: The primary colorant----〉Color matching by auxiliary color paste----〉stick----〉packaging, aluminum?paint: Aluminite powder soaking----〉resin----〉colour modulation, lustre adjusting----〉stick----〉packaging, powder coat: Resin,filler,pigment,auxiliary---〉mixing---〉extrusion---〉cooling---〉smashing---〉sieving---〉 packaging.

- Q:What's the fire endurance of hollow brick?

- For hollow brick wall, it should be noted that outside are 200-thick coal gangue hollow brick wall on interior wall. Besides, the fire endurance should comform to GB50067-97 Fireproof code for garage, repair garage, parking lot design. 3), All joints of brick walls and concrete wall column should reserve rebar tie. Masonry mortar in internal and external walls should be full. Wall masonry should be up to bottom of beam slab and filled tightly with 1:3 cement mortar.

- Q:Who knows about the grade C fireproof door materials?

- Wood or steel materials are usually used in them. The new national standard fire doors: According to the enacted GB12955-2008, the fire endurance of grade C fire doors is 0.5 hours and that of grade A and B are 1.5 hours and 1.0 hours respectively.

- Q:How to make the service life of refractory materials longer?

- Take acid resistant refractory materials as example: the atmosphere should be acidic atmosphere, if used in an environment whose temperature is 1900℃, it would exacerbate the loss of refractory materials, so don’t use overloaded. Second, select the appropriate refractory materials according to the environment. For example, if its operating temperature is 1800℃, generally speaking, the normal use of it according to the instruction of refractory materials would be fine.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

High Purity Calcined Bauxite Powder Supplied by CNBM

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords