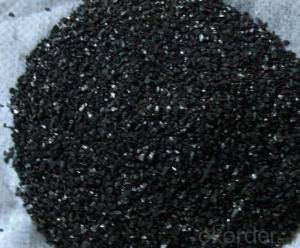

high purity amorphous graphite powder as additive

- Loading Port:

- Shekou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20.5

- Supply Capability:

- 1055 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Introduction

1. Silicon carbon can be used as metallurgical deoxidizer and high temperature resistant materials in smelting.

2. It can also be used as abrasive materials,which can be used to make abrasive tools,such as grinding wheels, oilstones, grinding head and so on.

2. Features

Silicon carbon is a new kind of reinforced steel-making deoxidizing agent and ideal thermal insulating agent.it is used for deoxidizing. The usage dose is 1-4kg/t can make electricity consumption to reduce 15-20kw/h and time to reduce 15-20min per furnace to raise productivity rate to 8-10%.

With high quality, reasonable price and timely delivery, our products have been export to many foreign countries and areas, such as South Korea, Japan, Turkey etc. our company has got praise in both domestic and foreign markets.we have been the trusted and preferred supplier to the mineral&chemical products and the market share is growing rapidly and firmly. Warmly welcome all friends from domestic and abroad to cooperate with us

3. Specifications:

Grade | Sic% | FreeC% | Si+SiO2% | Fe2O3 | MgO% | H2O% |

Sic75 | 75±4 | 2.5±1 | 17±2 | 3 | 0.16 | <5 |

Sic65 | 65±4 | 4.5±1 | 23±2 | 4 | 0.12 | <5 |

Sic55 | 55±4 | 4.8±1.5 | 28±3 | 5±2 | 0.1 | <5 |

Sic45 | 45±4 | 5±2 | 31±3 | 7±2 | 0.1 | <5 |

4. FAQ:

(1) Large melting furnace, longer melting time, lead to more crystallization, bigger crystals, higher purity and less impurities.

(2) Good hardness, longer life.

(3) Chemical washed and water washed good cleanness. it is really good for your company

(4) Special treated products get higher purity, better toughness, and better grinding effect.

1.Sample for free for your test.

2.Provide professional product consultation.

3.Offer competitive price.

4.Have precise quality control department.

5.Taking photos during the production and shipment, send the photos to customers;

6. Documents Department, to serve customer professionally.

7.Always think of the customers and make the add-value.

5. Pictures

- Q:I was a major in geological engineering, in the practice of mineral petrology, the teacher asked, "the mineral composition of coal?" Is a mineral petrology, coal chemistry is not in, please master, senior students. Thank you

- Oxygen in coalOxygen is the third important component of coal. It exists in two states: organic and inorganic. Organic oxygen is mainly found in oxygen-containing functional groups, such as carboxyl (--COOH), hydroxyl (--OH) and methoxy (--OCH3) and so on. Inorganic oxygen is mainly found in water, silicate, carbonate, sulfate and oxide. The organic oxygen in coal decreases with the deepening of coal, and tends to disappear. When the content of dry ash free carbon is less than 70%, the oxygen content of lignite can reach more than 20%. When the carbon content of bituminous coal is near 85%, the oxygen content is almost less than 10%. When the carbon content of anthracite is above 92%, the oxygen content is reduced to less than 5%.

- Q:Tell me the trouble which the coal index English code in this format please tell me - - water - ash volatile sulfur - fixed carbon - coke slag characteristics of heat - Requirements: the last edition of the new national standard GB and best can mark up compared with the old standard, the new national standard is different, in the measurement and as a way of testing, please inform. .

- Coal five common indicators for you to do reference.The first indicator: moisture.The moisture in coal is divided into internal water, external water, crystal water and water.The water is too large, is not conducive to processing, transportation, combustion will affect the thermal stability and thermal conduction, coking will reduce the coke yield and extend the coking cycle.

- Q:The greater the number of powdered activated carbon adsorption effect is better?

- According to practical experiences, such as the water in the mouth of adding water, in order to make full use of adsorption capacity of activated carbon powder, should be used to more than 250 mesh powder activated carbon; but at the same time must be strictly controlled the sedimentation tank effluent turbidity is about 1NTU, the strict control of filtration velocity? Dosage and larger in coagulation after precipitation plus water, should use less than 200 powdered activated carbon, to ensure the quality of tap water

- Q:What is the role of coal

- 5) living coal: the number of living coal is also large, accounting for about 20%. of fuel coal6 metallurgical power coal: Metallurgical power coal is mainly used for sintering and blast furnace coal injection, the amount of less than 1% of the coal used for power

- Q:What is the role of circulating fluidized bed boiler in coal - fired air system?

- : 1) to ensure the hot flue gas channeling but.2 furnace) to spread to the coal machine down coal can better into the hearth inside

- Q:What is the difference between how to distinguish

- If the barbecue food, the best use of the original charcoal, mainly fruit charcoal, charcoal, charcoal, tussah litchi Zaomu carbon, if you are ready to go to the end of the guests, which can.

- Q:Powdered activated carbon and globular activated carbon which is good

- If you recommend the use of coconut shell activated carbon, because it is the best performance of conventional activated carbon, drinking water filtration are also used in coconut shell activated carbon!

- Q:White melon seeds produced by the mechanism of carbon why taste

- Raw materials of ordinary charcoal is generally mixed, this is the original charcoal charcoal, more environmentally friendly, without any chemical additives, if used in the barbecue is a smoke-free non-toxic, combustion time in 1.5 hours; it is wood charcoal residue, peanut shell, straw who do, and binder. Toxic, burning time in 1-3 hours, but now some manufacturers production mechanism of carbon by high pressure pressing process, adhesive usage can be ignored; charcoal is the best on the market now binchotan, is growing at an altitude of 2000 meters above the tungsten oak trees in accordance with the Japanese side experts in the design of binchotan charcoal kiln from this, binchotan completely smoke-free non-toxic, combustion time in 5 hours, and 1100-1200 degrees in the fire, with far infrared function, you can make for a barbecue Our food is more delicious.

- Q:First of all, I would like to ask is: what is the need for steelmaking coal or anthracite coal? How much coal can be made of steel? Understand the answer or add friends do not understand this!! ~

- Do you dare to use coal? Play where. There are farmers used, 10% ingot of molten steel and bean curd residue, because more sulfur.

- Q:How to identify true and false activated carbon

- Traditional quality identification methodFirst, the activated carbon placed in the water to see if it will produce bubblesThe activated carbon placed in the water, if it produces a series of small bubbles, and there is a bubble sound, it shows that the activated carbon adsorption capacity, quality is particularly good

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

high purity amorphous graphite powder as additive

- Loading Port:

- Shekou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20.5

- Supply Capability:

- 1055 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products