High Purified Graphite Mould

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 Pieces pc

- Supply Capability:

- 1000 Pieces per Week pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Detailed Product Description

graphite qaulity:ISO9001

produce graphite mould as per drawings

supply graphite product stably

mould making in industry field

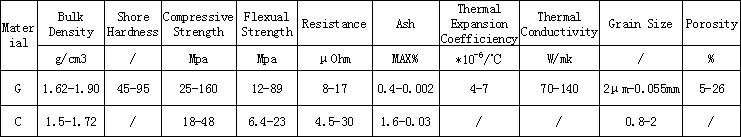

The physical and chemical properties of C and G material:

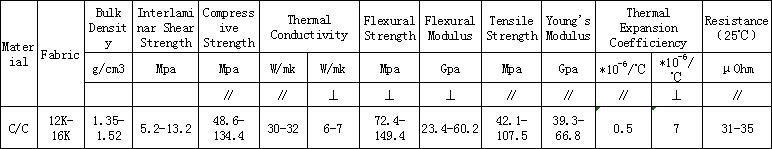

The physical and chemical properties of C/C material:

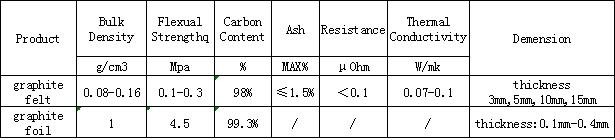

The physical and chemical properties of other material:

Products of carbon and graphite are widely used in such fields as industrial furnaces, mono-crystalline silicon machinery, mono-crystalline silicon machinery, electron, semi-conductor, metallurgy, oil, chemistry, textile, electrical machinery, electrical equipment, electrical furnace, traffic, communication industry, medicine, etc.

Providing graphite heating systems used in mono-crystalline silicon and multi-crystalline silicon industrial furnaces (such as heaters, thermal insulation material, insulation materials, etc.)

Providing graphite moulds, molds, graphite felt, graphite foil, graphite rod, graphite sheet, utensils, crucibles used in furnaces(such as graphite boats ,outer molds, mounting plates, etc.)

Providing graphite crucibles and utensils used for particular amorphous metal, rare metal, and non-ferrous metal and crystallizers for the growth of ferrous metal, etc.

Providing mechanical seal parts, graphite rings, graphite bearings, graphite leaf

Providing carbon felt, carbon cords, graphite power, graphite felt, and compound carbon felt of different specifications

- Q:How many times can a graphite hot bending die be used at most?

- The size of the hot bending die is different from that of the operator.3, the working environment affects the life.

- Q:Where can I sell graphite mould?

- Many domestic graphite products factory can produce graphite mold. Like Pingdingshan City Ruida graphite manufacturing Co., Ltd., the production of graphite mold, high quality and low price, good service. Recommend it to you.

- Q:Can graphite powder be used as moulds?

- I don't think so. The hardness is not enough. General mold die frame are used S50C. The hardness is from 170 to HBW. The hardness of graphite powder is only 1~2.

- Q:Graphite mold glass mold stamping?

- The general definition of mold: in industrial production, special tools with various presses and presses installed in the through pressure on the metal or non-metallic materials to produce the required shape parts or products, this special tool referred to as mold.

- Q:How do you sell graphite?

- Negative materials graphite powder: mainly used for lithium-ion batteries and other power batteries as negative electrode materials, electric vehicles are now so fire, graphite anode material market is not a problem.

- Q:Graphite mold maintenance

- Maintenance in production:1. when the mold is used, the guide post and guide sleeve should be lubricated regularly2., in the production of regular corresponding parts and edges of the mold should be repeated lubrication or stamping oil3. in addition to other items prohibited double punching, stamping materials, lubricants should be far away from the work area.4. edges of the iron powder can not delay too much, should be timely source of retention of materials and regular cleaning of scrap, after the end of the production of the mold to conduct a comprehensive inspection, comprehensive cleaning, guarantee the cleanliness of the mold.

- Q:How do graphite blocks do mirror treatment?

- And then use a little more of the whetstone for grinding, to be polished rough sanding marks after grinding, and then change the 1000# size of the whetstone grinding.

- Q:What are the electrodes on the die?

- Some shapes of electrodes cannot be made of copper, but graphite is easier to shape. Copper electrode is heavier (graphite, 1/5 of copper), which is not suitable for processing large electrode, which is also one of the reasons for using graphite electrode. The mold factory, from copper electrodes to graphite electrodes, needs to understand how to use graphite materials and consider many other factors. Graphite is divided into different grades and the ideal results can be achieved by using proper grade graphite and machine parameters in special applications. For example, the machine operators using graphite electrodes use the same settings as the copper electrodes, and the results are disappointing.

- Q:I do stretch die for nodular cast iron, which can tell me the mold heat treatment method, the specific Cui fire a few degrees?

- The mechanical properties of ductile iron mainly depend on the matrix structure because of the small separation of spherical graphite on matrix, so the mechanical properties of nodular cast iron can be significantly improved by heat treatment.

- Q:What are the suppliers of mobile 3D glass hot bending graphite die?

- Currently, smartphone heating is a normal phenomenon, this is because most of the smart phones are using high-performance CPU, this year there are many new mobile phones using dual core, quad core, or even eight nuclear CPU.

1. Manufacturer Overview |

|

|---|---|

| Location | Beijing,China (Mainland) |

| Year Established | 1998 |

| Annual Output Value | US$5 Million - US$10 Million |

| Main Markets | 70.00% Domestic Market 10.00% Eastern Europe 10.00% Western Europe 5.00% North America 5.00% Southeast Asia |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | xingang |

| Export Percentage | 21% - 30% |

| No.of Employees in Trade Department | 6-10 People |

| Language Spoken: | English, Chinese |

| b)Factory Information | |

| Factory Size: | 30,000-50,000 square meters |

| No. of Production Lines | 8 |

| Contract Manufacturing | OEM Service Offered |

| Product Price Range | AVERAGE |

Send your message to us

High Purified Graphite Mould

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 Pieces pc

- Supply Capability:

- 1000 Pieces per Week pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products