High Pure Whiteness Al2o3 Powder with High Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

High Pure Whiteness Al2o3 Powder with High Quality

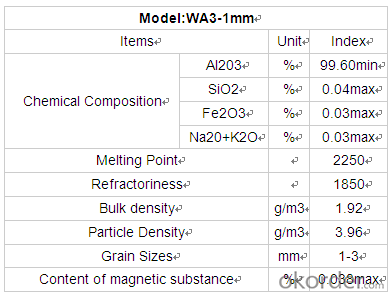

Specification:

High purity AL2O3 Aluminum Oxide/ Aluminum powder

Manufacturer

Superfine

Application:

1. aluminium oxide for aluminium smelting, glass, ceramic industry etc.

2. aluminium oxide for refractory, coating, abrasive applications.

3. aluminium oxide for electric basal plate, desiccating agent, chemical and pharmacy industry, etc.

aluminum oxide property:

It has higher hardness and slight lower toughness comparing with brown fused alumina. It is also characterized by its high purity, ability of self-sharpening, better cutting, less heat emit, higher efficiency, acid and alkali resistance, good thermal stability. As the abrasive materials, it is suitable for grinding high-speed, high carbon steel, as loose grains, it widely used for bonded and coated abrasives , polishing, precision casting and so on .

white fused alumina grits&powder chemical composition

aluminum oxide property:

Soluble in water white solid. Odourless. Tasteless. Qualitative very hard. Easy absorption of moisture and not ChaoXie. Both sexes oxide, soluble in inorganic acid and alkaline solution, almost insoluble in water and the polar organic solvents. The relative density (d204) 4.0. Melting point about 2000 °C.

The physical and chemical analysis:

Main standard:

Alumina(industry grade) made by slkali-lime sintered,It is white powdered crystal with low assay of Ti, Mn, Zn, Cu, V, Zr, Cr, Li, Pb, B, P, etc.It is used in the production of fused salt eletrorefining aluminium, corundum eramics, refractories and other alumina chemical products.

Product Pictures:

If you’ve any enquiry please don’t hesitate to contact us!

- Q:What are the specific steps of stirring the steel ladle castable?

- Steps are as follows. 1 Compulsory mixer is used to stir the castable and bags, rope and other debris can not mix in the castable when stirred. 2, Castable should be unpacked on the scene. Stirred volume depends on the capacity of the mixer. Castable should be accurately measured and put into a blender. 3 The process of first dry mixing and then wet mixing is adopted. After the castable is added to the mixer, it is dryly mixed for 2 minutes, add about 5.2 to 5.5 percent of water and continue to add water while stirring. Water that is 80% of the total should be added, and then decide whether to continue to add or not depending on the consistence (noting that the water must be clean water and sewage can not be used). Then it is wetly mixed for 4 minutes and stirred for not less than 6 minutes at one time, until castable is even. In general, the bottom is slightly dry and the wall of the ladle is slightly dilute (the amount of water is only for reference). 4, The amount of water and mixing time should be controlled strictly when stirred to ensure that the needs of the consistency are met. If castable is too thin, it will seriously affect the quality of the material. The stirred volume, stirring time and water that is added should be consistent and they can not suddenly be thick or suddenly be thin. If the consistency does not meet the requirements, the castable should be put back to the mixer and stirred with appropriate water or dry materials. 5, It should be stirred evenly and casting should finish in 20 minutes, in order to avoid sclerosis, affecting structural strength of ladle lining 6, After each completion of construction, varieties of castable should be changed and the mixer should be cleaned 7, Stirring can stop in halfway. If the mixer breaks down and it can be repaired in a short time, some of the materials have to be removed before the machine is opened. If the machine can be repaired on time, castable refractory should all be removed.

- Q:What kinds of fireproof materials does the safe use?

- The fireproof materials of the safe, cement foam. It is often said recently that the safes with cement inside are bad. Actually, it is not like this. Chemical means are taken to make the cement inside safes rise like a leaven dough so as to achieve good insulation. The principle is the cement foam. Fireproof safes with such techniques have good performance in terms of fireproofing and anti-theft. The manufacturing processes of this fireproof safe are highly technical, some safes with poor techniques have problems in quality. Here are some data of the foam cement.

- Q:What requirements should refractory materials meet?

- Ladle is an necessary equipment to undertake molten steel and continuous casting. As many kinds of steel needs to be processed in the ladle, including argon blowing tempering, alloy composition fine-tuning, refining dusting and vacuum processing, working conditions of the ladle lining have worsened. Their working conditions are as follows. (1) The temperature of molten steel is higher than mold casting ladle. (2) the molten steel stays longerin the ladle. (3) ladle lining are subjected to volatilization and agitation of molten steel under high temperatures and in vacuum. (4) The impact on the lining when undertaking steel liner when the impact effect. Therefore requirements of the ladle refractories are as follows: (1) It can resist high temperature. Molten steel should be able to withstand high temperatures without melting. (2) It can resist thermal shock and can withstand molten steel without cracking and spalling. (3) It can resist slag erosion. The ladle should be able to withstand the erosion of lining caused by slag and alkalinity changes of slag. (4) it should have sufficiently high temperature mechanical strength to withstand the agitation and scouring of molten steel. (5) lined should have certain swelling property so that lining will be united as a whole under the effect of hyperthermal molten steel.

- Q:What do refractory materials include?

- What refractories are included? Refractories include AZS brick, corundum brick, direct-bonded?magnesia-chrome, carborundum brick, silicon nitride bonded silicon carbide brick, non-oxide refractory materials such as nitride, silicides, sulfides, borides and carbides, oxidation calcium, chromium oxide, aluminum oxide, magnesium oxide and beryllium oxide.

- Q:Who knows the highest temperature the high-temperature refractory coating can resist?

- The temperature resistance degree of high temperature coating is different according to different coating types. The temperature resistance degree is vary from tens to thousands, magnesia brick: Greater than 2000 degrees dolomite brick: Greater than 2000 degrees casting corundum brick: Greater than 1990 degrees. The above data come from the network, for reference only.

- Q:Physical and chemical indicators of various refractory.

- There are too many of them.

- Q:For refractory, why is it necessary to store the first mixing materials for some time under proper moisture and temperature?

- It is mainly to remove gas form chemical reactions in the pug, give full play to plasticity and binding properties of combined, and store unburned?brick whose cememting agent is phosphoric?acid or aluminium?phosphate for some time under proper moisture and temperature. For example, to avoid the formed bricks in the initial stage of drying and firing form cracking due to hydration of calcium oxide. Mixing materials is to store the first mixing materials for some time under proper moisture and temperature in order to improve the evenness and moldability of pud, such as making the distribution of combined clay and water more even. The length of storing chiefly depends on the process requirements and the characteristics of blanks. For the producing pug of high temperature kiln furnitures, the storing time is longer. The function of storing mxing materials varies with different natures of blanks. For honeycomb ceramics, it is to fully digest calcium oxide in blanks. For storing magnesia brick blanks containing much calcium oxide, it should be stored for some time in proper humidity and temperature.

- Q:How long is the duration of fire resistance that fireproof window of level B can endure?

- Level B refers to the fire resistance rating and different hours in fireproofing of the fireproof window. Fireproof window of level A can endure fire for 1.5 hours while level B, 1.2 hours

- Q:Who knows about the fire endurance of grade C fire doors?

- It can be classified according to the fire endurance and thermal insulation performance: The fire endurance of grade A fire doors is not less than 1.5 hours; that of grade B fire doors is not less than 1.0 hours; and that of grade C fire doors is not less than 0.5 hours. I hope my answer can help you.

- Q:How many refractories are there for boiler above 1200 ℃?

- In addition to refractory brick, refractories include refractory concrete (refractory cement+aggregate), fire-resistant insulating layer (refractory cement+vermiculite powder or refractory cement + diatomaceous earth) and the like. Refractories often used are azs brick, corundum brick, direct-bonded?magnesia-chrome?bricks, carborundum brick, silicon nitride bonded silicon carbide brick, nitride, silicide, sulfide, boride, carbide and other nonoxide refractory materials, calcium oxide, chromium hemitrioxide, aluminium oxide, beryllia and other refractories. Thermal insulation refractory materials often used are diatomite product, asbestos product, insulation?board,etc. Unshaped refractories often used are repairing?mass, ramming?mass, castable refractory, plastic refractory, refractory mortar, refractory gunning mix, sling refractory, refractory coating, lightweight refractory?castables, stemming, etc.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

High Pure Whiteness Al2o3 Powder with High Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords