High-Pressure Laminates with High Quality Low Price

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Description of HPL:

Fireproof board, fireproofing veneer) also known as fireproof board, formerly known as layer is a thermosetting resin impregnated paper, high pressure decorative veneer, English abbreviation for HPL, surface decoration with refractory building materials a, rich surface color, decorative pattern and special and convenient processing. It is widely used in interior decoration on the surface of the material

HPL are high quality decoration material , which are widely applied to furniture,kitchen cabinet,cupboard, countertop, window, door skin, wall lining, partition, ship lining ,ceiling, lift lining, shop fitting,shelving, etc .

2.Feature of HPL:

1) Finishied via impregnating the decorative paper and kraft paper in melamine,drying and high temperature and presure

2) Outstanding resistance to abrasion,high tempreature,dirty,shocking,cigarette ignition and open flame

3) Exceptional mould proof performance ,has very wide application and very big market potential

4) Decorative surface material for both indoor and outdoor use

5) Widely used in surface decoration of rooms, offices, compartments, partitions, kitchens, sideboards, furniture and laboratory table tops

6) wear-resistant, fire-resistant, anti-static, chemical resistant

7) Acid resistance and alkali resistance

8) Easy be cut, easy be edge-covered in machine

9) Fireproofing

a) Abrasion-resistant, scratch-resistant, ray-resistant (depigmentation-resistant),

stain-resistant, impact-resistant and heat-resistant

b) Waterproof

c) Easy to be processed, without oil paint and waxing

d) Easy to be washed and cleaned

e) For interior decoration, suitable for kitchens, cabinets, teapoys, table boards,windowsills, ben doors and interior wall panels

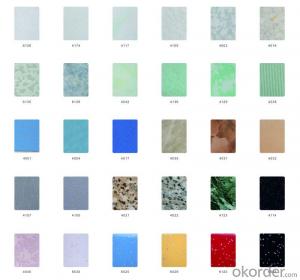

3.Images of HPL:

4.Specifications of HPL:

1. size

1220mmx2440mm 1220mmx3050mm 1310mmx2440mm 1310mm x3050mm

2. thickness

Standard HPL: 0.5mm~1.0mm.

Post-forming HPL: 0.5mm~0.6mm.

Metallic HPL: 0.7mm~1.0mm

Compact: 1.0mm~12mm.

3. color

Solid/plain color, fantastic color, wood grain color, metal, wooden veneer or customized color

4. surface finishing Glossy, Matt, Texture and some other special surfaces.

5. packing Wooden case for HPL/ wooden Pallet for Compact Laminate

0.5mm: LOAD: 14 cases per 20ft container, 600pcsX14cases=8400PCS

WEIGHT: 2.2KGX8400PCS+80kgX14cases=19.60TON

0.6mm: LOAD: 14 cases per 20ft container, 500pcsX14cases=7000 PCS

WEIGHT: 2.7KGX7000PCS+80kgX14cases=20.02TON

0.7mm: LOAD: 14 cases per 20ft container, 450pcsX14cases=6300 PCS

WEIGHT: 3.1KGX6300PCS+80kgX14cases=20.65TON

0.8mm: LOAD: 14cases per 20ft container, 400pcsX14cases =5600 PCS

WEIGHT: 3.6KGX5600PCS+80kgX14cases=21.28TON

5.FAQ

1. What kind of certificate do you have?

ISO9001, CE, UL,CARB, CNAS

2. What color can you produce?

Solid color wood grain color or according to customs' requirements.

3. How about the samples?

For the samples, it will be prepared ASAP.

4. Do you charge for the Samples?

According to our company policy, we will charge you the express fee in the first time but the sample will be free. While we start our business, we will reimburse the money for you

5. Can you produce according to customer's design?

Sure, we are professional manufacturer, OEM are welcome. While the beginning you need to pay the moulded open fees and Orders meet the minimum ordering quantity of special products

- Q:what is the price

- It is too much, list one or two, hope to help. Ceiling, wall materials and products. Such as: stone, inorganic fire baffle, gypsum board, glass magnesium plate, mineral wool board, silicon calcium board, calcium silicate board, fire door sandwich material ceiling ceiling materials, wall materials, fixed furniture panels, Other decorative materials and so on. Such as: fire-resistant aluminum-plastic composite panels, fire-resistant wallpaper, PVC plastic wall panels; flame retardant plywood, the flame-retardant treatment of the board wall materials, fixed furniture panels, decorative panels and other decorative materials. Such as wood flooring, carpets, Material floor coverings wall (felt), curtains, curtains, decorative cloth cloth

- Q:What is the bulk density of rock wool A grade fireproof material?

- 60-220kg general use of different local requirements so different capacity

- Q:Will the fire paint in general can buy it? Guiqiu.

- Looking for me on the line, good quality, but also cheap

- Q:What is the fire door to do? What is the price?

- Steel, wood, or steel-wood composite can be folder within the fire sandwich panels, such as rock wool, perlite and the like

- Q:What are the fireproof materials for Class A roof insulation?

- Roof insulation materials, vermiculite and vermiculite brick

- Q:What is Class A Fire What is Class B Fireproof?

- Class A, B level in two different standards, please do not confuse. A-level assessment criteria for the GB8624-1997, and B-level GB8624-2006. GB8624-1997 medium-level mainly: A-class, B1 level, B2 level, the current standard has been void, replaced by GB8624-2006. In the GB8624-2006, the general material classification: A1 grade, A2 grade Chuanchuan devaluation collision turtle sandstorm, B, C, D, E, F, floor material: A1fl level, A2fl AC, insulation, insulation material: A1L level, A2L level, BL level, CL grade, DL level, EL level, FL level, the above level are from high to low level, Bfl level, Cfl level, Dfl level, Efl level, Ffl level arrangement. GB8624-1997 A level can correspond to GB8624-2006 in the A1 and A2 level. The difference between the old and the new standard is that the A-level is only tested for incombustibility, while the A1 level detects the incombustibility and total combustion calorific value, the A2-level test incombustibility, the SBI monomer combustion test (or the total combustion calorific value, the SBI monomer combustion test , One of the two). While the B-level test items for the SBI monomer combustion test, flammability and so on. Details if you need, please leave the mailbox, I sent you.

- Q:Ventilation duct fan outsourcing fireproof material specifically what

- 8.5.6 Ventilation, air conditioning system piping, etc., should be made of non-burning materials, but contact with corrosive media duct and flexible joints, can be made of refractory materials. 8.5.7 Insulation materials, silencers and adhesives for pipes and equipment shall be non-combustible materials or refractory materials. Through the firewall and deformation of the duct on both sides of the 2.00m should be used within the scope of non-combustion materials and binders. 8.5.8 When the electric heater is installed in the duct, the fan shall be interlocked with the electric heater. Electric heater before and after the 800mm within the duct and through the fire and other places with easy fire parts of the pipeline, must use non-combustible insulation materials

- Q:Is plastic as a fireproof material?

- ABS is not a modified flame retardant ABS material that is ABS fire

- Q:Decorative materials Fireproof paint three degrees What does it mean

- Fire paint three degrees, three degrees is three times (times), different fire retardant coating requirements in the construction is not the same. Fire retardant coating is used for combustible substrate surface, can reduce the surface of the coating material flammability, blocking the rapid spread of fire, used to improve the refractory limit of the coating material of a special coating.

- Q:Are you using fireproof materials for decoration?

- Sure to ah, such as the switch panel burned, there must be a layer of Shuo plastic bedding, not easy to cause flammable, but also early hair problems

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

High-Pressure Laminates with High Quality Low Price

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords