High-Pressure Laminates Wholesale Price from China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Description of HPL:

HPL are high quality decoration material , which are widely applied to furniture,kitchen cabinet,cupboard, countertop, window, door skin, wall lining, partition, ship lining ,ceiling, lift lining, shop fitting,shelving, etc .

Fireproof board / refractory plate is base paper after melamine resin and phenolic resin processing, main physical properties is unfolded by the characteristics of the resins. After the melamine resin thermosetting moulding have luster good, good transparency, high surface hardness, wear-resisting, withstand high temperatures, impact resistance, surface pores small is not easy to be contaminated, chemical resistance, water resistance, resistance to solvent, flame resistance and other excellent performance, mechanical strength, electrical insulation, resistance to arc good and is not easy to aging. Phenolic resin thermoset molding after heat and hard performance. Two kinds of resin combination, fireproof board / refractory plate contains both the performance.

2.Feature of HPL:

1) Finishied via impregnating the decorative paper and kraft paper in melamine,drying and high temperature and presure

2) Outstanding resistance to abrasion,high tempreature,dirty,shocking,cigarette ignition and open flame

3) Exceptional mould proof performance ,has very wide application and very big market potential

4) Decorative surface material for both indoor and outdoor use

5) Widely used in surface decoration of rooms, offices, compartments, partitions, kitchens, sideboards, furniture and laboratory table tops

6) wear-resistant, fire-resistant, anti-static, chemical resistant

7) Acid resistance and alkali resistance

8) Abrasive resistance

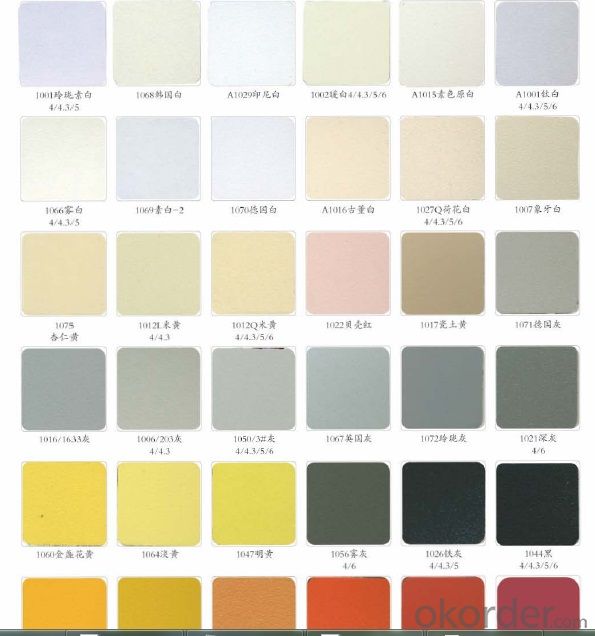

9) Amazing colors and rich in colors. High glossy and matte is available.

10) Easy to clean

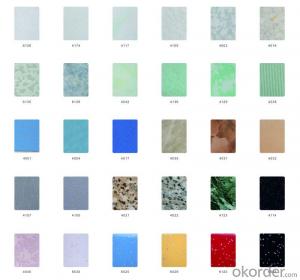

3.Images of HPL:

4.Specifications of HPL:

1. size

1220mmx2440mm 1220mmx3050mm 1310mmx2440mm 1310mm x3050mm

2. thickness

Standard HPL: 0.5mm~1.0mm.

Post-forming HPL: 0.5mm~0.6mm.

Metallic HPL: 0.7mm~1.0mm

Compact: 1.0mm~12mm.

3. color

Solid/plain color, fantastic color, wood grain color, metal, wooden veneer or customized color

4. surface finishing Glossy, Matt, Texture and some other special surfaces.

5. payment 1) T/T 30% in advance, 70% before shipment 2) L/C at sight

6. delivery time It depends on the specific order quantity

7.minimum order quantity 2000 PCS

5.FAQ

1. What kind of certificate do you have?

ISO9001, CE, UL,CARB, CNAS

2. What color can you produce?

Solid color wood grain color or according to customs' requirements.

3. How about the samples?

For the samples, it will be prepared ASAP.

4. Do you charge for the Samples?

According to our company policy, we will charge you the express fee in the first time but the sample will be free. While we start our business, we will reimburse the money for you

5. Can you produce according to customer's design?

Sure, we are professional manufacturer, OEM are welcome. While the beginning you need to pay the moulded open fees and Orders meet the minimum ordering quantity of special products

- Q:what is the price

- This problem you are online to ask, it seems that you do not understand the decoration, but also to undertake the decoration of KTV, it is not willing to tell you.

- Q:What is the fire insulation material

- Materials are: aluminum silicate fiber felt, inorganic mineral raw materials, perlite, glass fiber, ceramic fiber, mullite fiber, basalt fiber, high silicone fiber. Barrier insulation coating is a low thermal conductivity and high thermal resistance to achieve a thermal insulation coating. The most widely used barrier insulation insulation coating is a composite silicate insulation coating. This kind of coating is developed in the late 1980s, with different product names, such as composite magnesium aluminum silicate insulation coating, rare earth insulation coating, coated composite silicate insulation coating. It is made of inorganic and / or organic binder, insulation aggregate (such as sepiolite, vermiculite, perlite powder, etc.) and air entraining agent made of insulation coating. The performance requirements of such coatings can be found in GB / T-1998 "Silicate composite insulation coating". Composite silicate insulation coating Although the thermal conductivity is low, the cost is low, but the drying cycle is long, the impact resistance is weak, dry shrinkage, moisture absorption rate, low bond strength, poor decorative effect. This type of coating is currently used primarily for the casting of molds, tanks and pipes. This coating is currently not used for exterior insulation. In the future through the modified, is expected to be used for external wall insulation system.

- Q:Performance and Difference of Rockwool and Glass Fiber Fireproof Materials

- Rock wool and glass wool fire rating are all A-level rock wool high temperature of 800 degrees glass wool high temperature 450 touch tiger whip mortar Zhuang Huan Biao cloth wave density rock wool relative weight of some glass wool bulk light from the waterproof performance or glass wool better some

- Q:Building ceiling material fire rating

- Divided into four grades, non-flammable, flammable, flammable, flammable...

- Q:Wood-plastic material fire?

- Fire rating is classified. Can not simply say that wood-plastic material fire or not. According to the composition of wood-plastic materials, which is mainly plastic and wood powder, in order to increase the fire resistance of wood-plastic, plus a certain amount of flame retardants, but the type and number of flame retardants and a direct impact on the fire for the box The performance of the valley. At present, many wood-plastic materials, the highest level of fire should be in the B1 level, the need for a stronger fire rating, then the need for special formula, many companies can not do a class A fire rating. Detailed advice ::

- Q:What does the fire board use?

- Tianhua new materials professional answer you, fire board as the name suggests is a fire function of the plate. However, the fire, not that is sure to be able to prevent the flames burning muscle chiffon pay Guigui helium riveting, it is more of the meaning of fire-retardant, evacuation rescue for the staff to fight for time. Because, even if the metal material, the flame will melt a long time to melt Oh. Fire is currently divided into organic fire board, inorganic fire board two categories. Organic fire board is our common woodworking board affixed to the protective cover of the Oh, the fire rating is B1 flame retardant sector. With the national and social attention to fire and fire, inorganic fire board is being used by more and more people. Inorganic glass magnesium fire board, with the highest A1 non-combustible level, to adapt to the people's growing fire needs. But the quality of glass magnesium board uneven, from a few dollars to a few hundred dollars a range, so you have to choose Oh well But please remember that the price is the value of the reaction, a sub-price goods Oh!

- Q:What is fireproof material? Fireproof material and insulation materials, refractory material is the same thing?

- Not the same, fireproof materials used to prevent the burning of the tripod foot Jiabing yellow wilt wear burning, to prevent burning. The refractory material is able to withstand high temperature fire, play the effect of insulation and withstand the role of high temperature furnace

- Q:What are the materials for the kitchen ceiling that meet the fire protection requirements?

- In all the interior decoration of the fire design, the ceiling of the fire design in the most important position. This is because the fire is burning up the fire, the ceiling first and directly accept the fire test; the same time, there is a direct impact on the evacuation, will directly constitute a threat to the safety of evacuated personnel. Therefore, in the interior ceiling decoration design, should give full consideration to its fire problem. "Fire protection within the building design fire code" on the different civil buildings of indoor ceiling material fire performance has a detailed requirement. Ceiling (prungroof), refers to the roof of the living environment of the decoration. The ceiling is an important sub-division of the building decoration project. The ceiling has the function of insulation, insulation, sound insulation and sound absorption. It is also a hidden layer of electrical, ventilation and air conditioning, communication and fire prevention, alarm pipeline equipment and so on. The ceiling in the whole room decoration occupies a very important position on the top of the room for the appropriate decoration, not only to beautify the indoor environment, but also create a colorful interior space art image. In the choice of ceiling decoration materials and design programs, to follow the two materials, solid, safe, and beautiful, practical principles.

- Q:Production of fire paint business should have what qualifications

- Production of fire retardant coating enterprises should have the requirements of ordinary production enterprises qualified business license, organization code, tax registration certificate, system certificate, type approval certificate, public security fire for the record. Fire retardant coating is used for combustible substrate surface, can reduce the surface of the coating material flammability, blocking the rapid spread of fire, used to improve the refractory limit of the coating material of a special coating. Applied to the surface of the combustible substrate, to change the surface of the material combustion characteristics, blocking the rapid spread of fire; or applied to the building components, to improve the fire resistance of the components of the special coating, called fire retardant coating. Fire retardant coating is by brushing the surface of those flammable materials, can improve the material's fire resistance, slow the spread of flame propagation speed, or in a certain period of time to prevent burning, this type of coating known as fire retardant coating, or called flame retardant coating.

- Q:Height greater than 60m residential building construction, when the use of B1-class insulation material, every few layers to set the level of fire isolation belt?

- (A) residential construction should meet the following requirements: 1, height greater than or equal to 100m of the building, the insulation of the combustion properties of the material should be a bile to pick up the state. 2, the height is greater than or equal to 60m less than 100m of the building, the insulation properties of the combustion performance should not be lower than B2. When using B2 insulation material, each layer should be set to a level of fire isolation zone. 3, the height is greater than or equal to 24m less than 60m of the building, the insulation of the combustion performance should not be lower than B2. When using B2 insulation material, each two layers should be set to the level of fire isolation zone. 4, the height of less than 24m of the building, the insulation properties of the combustion performance should not be lower than the B2 level. Among them, when the use of B2-class insulation material, the three should be set up a horizontal fire isolation zone.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

High-Pressure Laminates Wholesale Price from China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords