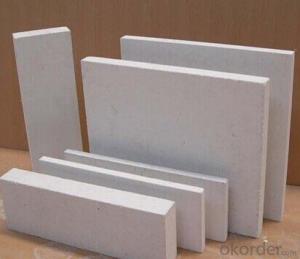

High Performance 100% Non Asbestos Magnesium Oxide Board

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

1. Fire resistant, ASTM E84

2. Environmentally friendly

3. Waterproof

4. 100% non asbestos

5. Light weight but durable

Materials: MgO, MgCl, Inorganic textile and Pertile |

Size: 1200 x 2400/1220 x 2440mm |

Thickness: 6mm, 9mm, 10mm, 12mm, 18mm |

Density: ≥ 800 kg/m3 |

Moisture content: ≤ 12% |

Impact strength: ≥ 20N/mm2 (12MM) |

Bending strength: ≥12.1N/mm2 |

Tensile Strength: ≥1.97N/mm2 |

Flame Spread: 4.7 |

Smoke Spread : 27 |

Fire resistance: ASTM E84 08 CLASS A & DIN 4102-1, 1998 Class A1 |

Freeze Strength: after 25 times freezing thawing cycles, no delaminating |

Thermal conductivity: ≤ 0.17/W.mK |

Water absorption: ≤ 40% |

Asbestos content: Not detected |

Formaldehyde content: Not detected |

Radioactivity: GB6566 2001 A Class |

Sound insulation: 55 db (12MM) |

Water Resistance: after 24 hours test, there wasn’t water percolation or water drop on the back side (12mm thickness) |

Magnesium oxide board is a fireproof and thermal insulation building material. It can be used for a number of applications including wall and ceiling linings, fascias, soffits, tile backing and underlayment. It is made of magnesium oxide, cellulose, pertile, and fiberglass scrim .

MgO board is in various thicknesses and sheet sizes. It also comes in various grades, such as smooth finishes, rough textures, and utility grades. It is white, beige or light gray in color.

Areas of Application

• False Ceiling

• Internal Walls - Half Height/Full Height

• Internal Wall Lining

• Eaves and Staff Lining

• Pre-fabricated Shelter-Internal/External walls

At present there are many types of boards available in market which have their own advantages as well as drawbacks. Win-Win Boards are the solution to all those drawbacks. They are five times better than any available board.

They are versatile, sustainable, high performance and eco-friendly building product.

Win-Win Boards are virtually impenetrable to fire, water, insects, termite, mould and mildew. They are non-toxic, non- flammable, completely free from asbestos and carcinogenic materials which are usually present in fibre cement boards and calcium silicate boards. They are dimensionally so stable that expansion and contraction is negligible in them.

These boards will not delaminate or deteriorate on continuous exposure to moisture, water or if exposed to freeze/thaw cycles for prolonged periods of time. They are ideal for high tech engineering applications, general purpose construction, especially for high humid area like bathrooms or shower enclosure, and off-site manufacture of wall, ceiling and floor panels in comparison of traditional wood, gypsum and cement based products.

Win-Win Boards are lightweight and strong, extremely quick and easy to install, reducing labour cost and building time.

- Q:I would like to be a multi-purpose cabinet, I do not know what kind of good plate, please master master guide, thank you

- The most light, the most environmentally friendly, so beautiful and practical man-made sheet is ecological wood.

- Q:2017 plate top ten brands

- China's top ten blockboard (Daixinban) brand 1 Bunny (China famous brand products, Daxin board joinery ten brands, Zhejiang famous brand, Huzhou City brand-name products, Dehua Group) 2 king coconut (well-known trademarks in China, China's top 500 brands, China's top ten brands of wood, the first Chinese woodworking board brand, Hangzhou King coconut holding) 3 Peng Hong (China famous brand, famous brand in Liaoning Province, Liaoning brand, China's wood-based panel industry leader, Dalian Peng Hong Wood) 4 Fuqing (China Famous Brand, Jiangsu Province, the famous brand, the top ten enterprises in China, Jiangsu Province, the largest plate enterprises, Jiangsu Fuqing set) 5 Hong Kong Pretty Beauty (international brand, plate aristocrat, China's first British art children's room for the board, the Asian brand 500, Hong Kong Pretty Beauty International set) Is one of China 's largest manufacturers of environmentally friendly decorative materials, is a collection research and development, students) 7 Fuhan (China Famous Brand, Hubei famous brand, well-known brands, China City, the industrialization of agriculture leading enterprises, Fu Han Wood Co., Ltd.) 8 years boat (China Famous Brand, Hangzhou famous brand, China's top ten brands, Zhejiang brand-name products, the Millennium Group Huahai Wood Co., Ltd.) 9 Hunan Wang (Huxiang Wang plate, China's well-known trademarks, China's top ten brands of plates, brand-name in Hunan, China's environmental labeling product certification) 10 Universal (Jiangsu Province, brand-name products, large-scale wood sheet processing and production enterprises, Nantong Fu Sheng Wood Co., Ltd.)

- Q:So steel products can be called steel, plates and profiles are steel classification.

- So steel products can be called steel, plates and profiles are steel classification. Plate by thickness in the plate, sheet, plate and plate. Separate the plates by the process. Cold plate, hot plate and so on. Profiles, as the name suggests, angle, groove just belong to the profile.

- Q:What are the characteristics of KRD blue epoxy sheet?

- "KRD blue epoxy plate" in 1938 by the German company in Switzerland patent application in Switzerland, 1946 secretly put into operation in the high-end military plate, in 2008 Germany Kerui De company in the original epoxy board formula based on improved by adding KRD blue Water resistant weather factor, to produce high-end "KRD blue epoxy plate", put the German market, mainly used in luxury cruise ships and high-end cars and high-end interior furniture production. October 2009 European style (Hong Kong) bathroom International Development Co., Ltd. formally introduced "KRD blue epoxy plate" production line into the civilian bathroom furniture production. ????"KRD blue epoxy sheet" has a strong chemical resistance and water resistance. In the curing system of ether, benzene ring and fatty hydroxyl is not susceptible to acid and alkali erosion. Can be used for two years in seawater, petroleum, kerosene, 10% H2SO4, 10% HCl, 10% HAc, 10% NH3, 10% H3PO4 and 30% Na2CO3, and half a year at 50% H2SO4 and 10% HNO3; % NaOH (100 ° C) for a month or soaked in fresh water for 50 years, the performance remains the same. ????"KRD blue epoxy plate" molecular chain structure contains two or more epoxy groups of polymer compounds, process performance is good, strong nail holding force, product size and stability, no radiation, zero formaldehyde, is the current The forefront of the international environmental health, strong weather resistance of high-end furniture preferred plate. "KRD blue epoxy plate" Appearance features: A high density light B The appearance of the plate is light blue C strong flexibility

- Q:High voltage switchgear shell plate thickness

- I really switch cabinet manufacturers work I do not know about other units, I know Our unit is 2 to 3 mm or so, the material is Complex aluminum zinc plate

- Q:What is the grade of the board?

- The country has not yet officially released on the E0 level of national standards, the current so-called E0 standard for the industry's most common convention. E0 means: less than or equal to 0.5 mg / l of formaldehyde emission E1 refers to: less than or equal to 9.0mg / 100g formaldehyde emission E2 means less than or equal to 30.0 mg / 100 g of formaldehyde emission

- Q:What kind of wood is the water-based material? Environmental protection?

- Water-based days is a professional engaged in water-based polymer research and application of high-tech enterprises. "Water-based technology, beautiful China" for the corporate mission, with the world's first water-based wet synthetic leather production line, China's first 100,000 tons of water-based polyurethane production line and China's first harmful chemical substances testing center. Water-based science days not only to create a new era of non-toxic home improvement, but also to promote water-based materials, furniture, synthetic leather and other areas of green environmental protection industry changes.

- Q:Baosteel Cr2, Cr3 plate what material

- CR2 is the standard of ISO 3574, equivalent to GB03 (GB / T 5213, or EN 10130), or standard SPCD (refer to JIS 3574), or American Standard CS Type A, B (refer to ASTM A1008M-07) ; CR3, equivalent to GB04 (GB / T 5213, or EN 10130), or standard SPCE (refer to JIS 3574), or American Standard DS Type A, B (refer to ASTM A1008M-07);

- Q:Decoration commonly used plate brand?

- Top 10 brands of board-off woodworking board Hebei Tengfei Wood Co., Ltd. is a private joint-stock enterprises, which was established in 1996, more than 800 employees, mainly engaged in sheet, multilayer, Glulam R & D and production. Plate top ten brands of Peng Hong. Dalian Peng Hong Wood Co., Ltd. was founded in 1997, is China's wood-based panel industry leader. The company's comprehensive production capacity and product sales in the domestic wood-based panel manufacturing industry in a leading position in the domestic market enjoyed a high reputation. Top 10 brands of Albert. Guangzhou Wei Zheng Wood Products Co., Ltd. was established in 1996, is a professional production of "Wei-licensing" green plywood of wood products large enterprises. The company has been committed to improving the human living environment, to create a harmonious home, tree industry standards, has made brilliant achievements.

- Q:Home improvement plate which brand the best ah? Environmental protection best?

- Like this kind of furniture plate material quality is good, only used to know, Fuxiang plate can be considered a very large enterprise in Hunan Province, and has been a good quality itself, you can personally go to their stores to see ah. Online question is also asked not to experience in order to understand!

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

High Performance 100% Non Asbestos Magnesium Oxide Board

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords