High-performace pipeline ball valve 1500 Class

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 100 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Products Description of pipeline ball valve

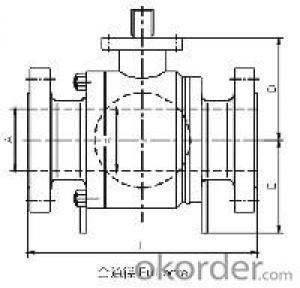

Body of high-performance pipeline ball valve is forged structure.The connection type for body and vice-body can be BB(bolted connection)and WB(welded connection).The WB(welded connection)and the LWB(Fully-welded extended stem)structure isadopted for buried ball valves,as shown below.

High performance pipeline ball valve series has the feature of strength,high perfect sealing,maintenance-free,long life and so on.The production of this series ball valve adopts the international advanced ball valve design and manufacturing technology,selects high-quality materials in accordance with the standard selection of materials and combines with advanced materials forming forging technology.At the same time,with the years of ball valve design and manufacturing experience,the use of advanced processing and manufacturing equipment and production and processing technology,through the first-class inspection and testing equipment and instruments,perfect quality assurance management system and excellence in the production of high-performance philosophy can ensure the quality of valves.This series of valve has the performance of a high strength,defect-free forging body,excellent sealing performance,even at maximum pressure difference(full pressure),it will still be able to ensure that seal without leakage,after frequent switching action to realize a safe usage in the transportation of oil,natural gas,coal gas,and other special medium transportation pipeline.

Performance & Dimensions of pipeline ball valve

Standard Criteria | ASME/ANSI/API customize |

Pressure Rating | 1.6 Mpa 2 Mpa 5 Mpa 8 Mpa 10 Mpa 16 Mpa 25 Mpa 42 Mpa |

150 Class 300 Class 600 Class 900 Class 1500 Class 2500 Class customize | |

Valve Size | 50 mm 80 mm 100 mm 150 mm 200 mm 250 mm 300 mm 350 mm 400 mm 450 mm 500 mm 550 mm 600 mm 650 mm 700 mm 750 mm 800 mm 850 mm 900 mm 1000 mm 1050 mm 1200 mm 1400 mm |

2 inch 3 inch 4 inch 6 inch 8 inch 10 inch 12 inch 14 inch 16 inch 18 inch 20 inch 22 inch 24 inch 26 inch 28 inch 30 inch 32 inch 34 inch 36 inch 40 inch 42 inch 48 inch 56 inch customize | |

Actuator | Electric Handle Hydraulic Pilot-hydraulic Pneumatic customize |

Connection | Butt Welding Flange RF Flange RTJ customize |

Medium | Gas customize |

Medium Temperature | -29~150℃ -46~150℃ customize |

Application Fields | Electricity Petrochemical Power Station customize |

Component Materials of pipeline ball valve

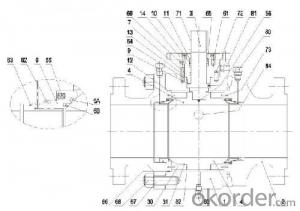

1-Body Material | A105 A350-LF2-M customize |

2-Bonnet | A105 A350-LF2-M customize |

3-Stem | 4410+ENP customize |

4-Ball | A350 LF2+ENP A105+ENP customize |

5-Material of Valve Seat | fluorine rubber customize |

5-Seat | Nylon PTFE peek DEVLON customize |

6-Seat ring | A105 ENP+A322 4140 customize |

7-Packing chamber | A322 4140+ENP A105 customize |

9-Stem gasket | RPTFE customize |

10-Packing | graphite PTFE customize |

11-Packing gland | ENP+A350 LF2 ENP+A105 customize |

12-Body gasket | Stainless steel+graphite customize |

13-Gasket | Stainless steel+graphite customize |

14-Top flange | A105 A350 LF2 customize |

30-Supporting board | A105 A350 LF2 customize |

31-Gasket | customize |

55-Seat spring | B637 Inconel X750 customize |

56-Anti-static spring | B637 Inconel X750 customize |

60-Bolt | A320 L7 A193-B7 A193-B7M customize |

61-Bolt | A193-B7 A193-B7M A320 L7 customize |

62-O-ring | fluorine rubber hydrogenated nitrile butadiene rubber customize |

63-Fire-safe ring | flexible graphite customize |

64-O-ring | hydrogenated nitrile butadiene rubber fluorine rubber customize |

65-O-ring | fluorine rubber hydrogenated nitrile butadiene rubber customize |

66-O-ring | fluorine rubber hydrogenated nitrile butadiene rubber customize |

67-Bolt | A193-B7M A320 L7 A193-B7 customize |

68-Nut | A194 2HM A194 4 A194 2H customize |

71-Key | A322 4140 customize |

72-Locating pin | A322 4140 customize |

73-Locating pin | A322 4140 customize |

80-Seat injection valve | WCB+ENP customize |

81-Stem injection valve | WCB+ENP customize |

82-Bearing | PTFE+Stainless steel customize |

83-Drainage valve | Stainless steel customize |

84-Vent valve | Stainless steel customize |

85-Actuator | customize |

90-Plate | Stainless steel customize |

Standards Applied of pipeline ball valve

Design Standard | API 6D customize |

Connection Standard | ASME B 16.25-2007 ASME B 16.5 ASME B 31.4 ASME B 31.8 DIN GB、GB/T JB、JB/T JIS customize |

Test Standard | API 6D customize |

Face to Face | API 6D customize |

Pressure-temperature rating | ASME B 16.34-2004 customize |

Marking | MSS SP-25 customize |

- Q:The valve on my mountain bike tire has a leak, so I want to go buy a new valve (and maybe a couple spares)... how much is the average cost?Thanks!

- It depends on whether you have a presta or schraeder valve. If a schraeder valve, you can buy a bag of them with a remover from an auto parts store for about $3.00 or so. If a presta valve, most of those cannot be replaced so it is new tube time. Are you sure it is a valve? Many times a puncture in the tube will leak through the valve hole AROUND the valve making it seem like a valve.

- Q:Where is the Auxiliary Air Valve on my 98 Civic?I have a 98 Honda Civic ex and need to change the Auxiliary Air Valve

- you don't have on the Civic. The Auxillary Air Valve is a part of the AIR (Air Injection Reaction) system used to control emissions on domestic vehicles. Honda doesn't use that part nor that system. there was another 'auxillary air valve' used in old Bosch fuel injection systems that added air when the car was in cold start enrichment. that part hasn't been used in the last 20 years by any manufacturer. The control of the idle at cold start is done by the idle air control valve. The idle air control valve located under the thottle body on most hondas; some models have it on the side. there are usually two vacuum hoses and one electrical connector to the valve. that valve controls the engine idle and when bad it would cause the engine to surge at idle. if that's not the case, then we need more information on what you are trying to fix and what you mean by auxillary air valve. if there is a diagnostic trouble code associated with it then that would help. hope that helps

- Q:How much would it cost to get a new valve cover gasket on a 1993 Nissan Quest van?? I know of a van for sale, but they said it might need a gasket soon. How much plus labor, average, do you think it'll cost? Thanks!!

- The valve cover gasket (parts and labor) is about $100 - $200 for the left side and $300 - $400 for the right hand side, but be sure you didn't misunderstand and the failing gasket is actually a head gasket. Those are a big deal: $1500 - $2000.

- Q:How would you change the Heater control valve on a 1997 honda civic hx?its my first car, so i dont know much about cars.

- You have to take the whole dash apart. Not an easy job, and definitely not one for a novice.

- Q:So I just got mu egr valve on my car replaced a year ago. Now it needs replacing again!? why might this be? shouldnt it last longer?

- Your EGR valve is not likely to be defective. Test it to make sure it's defective before you have it replaced. Just because a code reader or scanner reports an out of range reading, that doesn't always mean that the sensor or component is bad. All it means when a code reader or scanner reports an out of range reading it that there is a problem somewhere in that circuit. To test your EGR valve, or any other for that matter, just search the internet for how to test a ______ whatever.

- Q:What are the function of reed valves on a motorcycle?

- Reed Valves

- Q:My mom just went to DR and will have open heart next Thursday for removal of anyerisum. She was told she has 2 heart valves instead of four. What does this mean? Is it normal?

- Your mom probably has a Bicuspid aortic valve, that she was born with.. it means that the valve between her heart and the aorta has two valve leaflets instead of the usual three valve leaflets (not four) in normal people. Bicuspid aortic valve is caused by fusion of two of the three leaflets. It's a fairly common congenital condition, and is associated with a risk of aortic aneurysm (a weakening of the wall of the blood vessel which then causes ballooning of the vessel wall)...usually of the ascending aorta. All the best for her safe recovery.

- Q:Water has been seeping out of the sprinklers closest to the anti-siphon valve. Water seeps out of the sprinkler even when the anti-siphon valve is manually closed and not connected electronically. I opened up the anti-siphon valve to inspect the diaphragm, but there is no debris nor it was damaged. To be sure, I switched the diaphragm chamber of the two anti-siphon valves (a suspected leaky one and another good working one), but leak persists from the same sprinklers. I think the leak is from the (float?) rubber seal at the bottom of the stem closing the inlet valve. My anti-siphon is a Hardie (or Irritrol) model 311A series.1) Is my troubleshooting and logic correct? What other components could have contributed to the leak described? 2) At what scenario will water be flowing out of the anti-siphon cap?3) How can I determine if my anti-siphon valve has a vacuum breaker? What is a vacuum breaker good for?4)Which brand makes the most reliable anti-siphon valve?

- If the antisyphon valve is not leaking maybe you should focus attention on the main valve ( assuming it is a solenoid valve) to see if it closes completely. Another thing, if the irrigation zone is on an incline then the water in the system will drain to the lowest point. Sometimes it drains slowly causing the impression of a leaky feed valve.

- Q:Why are pig hearts valves used as replacements for damaged heart valves in humans? Are there any complications and are they still used today?

- The tissue is most like ours. Yes, they are still used. They have a low rate of rejection.

- Q:I acquired an old valve guitar amp not long ago and i think it needs new valves trouble is the valves that are in it have no writing left on them and there is one valve completely missing how can i find out what type of valves to put in it. Could i use a multi meter to see what voltage etc is going into the valve socket and then find a valve with matching voltage. Thanks for your help Marc

- Go okorder and search for the schematic diagram for your amp(enter the brand and model of your amp)!

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

High-performace pipeline ball valve 1500 Class

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 100 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords