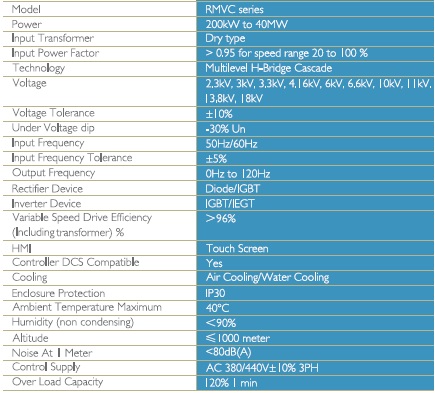

High Medium Voltage Drive 3KV 10000KW VFD

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Energy-saving Solutions for Enterprise

1、Program Overview

◆Saving energy achieves 10% -70%

◆The enterprises do not need to pay for expense of equipment manufacture and installation.

◆Enterprises only need to pay the saving electricity expense to our company according to the actual quantity of energy saving after the equipments put into operation.

◆According thousands of the projects’ implementation experiences, such projects recover the investments in three or four years. (Equipment service life is 15 years)。

◆Our company will no longer charge the saving electricity expense after recovering the investment.

The significance of the program:

1)、Concentrate on solving problems of energy conservation, make enterprises’ energy-saving work reach new level and take their social responsibility。

2)、Avoid the enterprises reactive power fine of low power factor caused by electric energy using (according to Ministry of Electric Power and Water Resources, State Price Control Bureau establish the " measures of power factor adjustment expense ").

3)、Avoid the high-energy consumption enterprises are implemented differential prices because of the changes of national power regulation.

4)、For the standard-conforming large-scale (saved energy equal 10 thousand tons standard coal or more) energy-saving technological transformation projects, China will reward the enterprises for energy saving which based on the "Financial Incentives Interim Measure for Energy-saving Technological Transformations" established by Ministry of Finance, the National Development and Reform Commission.( Amount of 200 yuan / ton of standard coal).

5)、Equipments recovery period is generally 3-4 years, each period payment equal to the amount of current energy-saving benefits, and equipments service life are 15 years, so enterprises will gain huge energy-saving benefits.

2、Implementation Process

Energy Audit

Energy Saving Program Design

Construction Design

Equipments Manufacture

Construction and installation

Maintenance and Repair

Energy Monitoring and Efficiency Insurance

Recovery of Program Investment

3、Program Features

High energy-saving efficiency

The project saving rate is generally 10% -30%, highest is up to 70%.

Clients Zero Investment

All works of design, audit, manufacturing, construction, monitoring are handled by RXPE, clients does not require investment.

Energy-saving Guarantee

RXPE promises the amount of energy saving, ensuring that clients’ cost reduction immediately.

Short Investment Recovery Period

The investment recovery period is short, average period is 3-4 years.

Low Risk

Customers do not input large sums of money also can enjoy professional energy-saving products, technologies and services, and the investment risk is very low.

Improvement of Cash Flow

Customers with the support of RXPE approve energy-saving program to improve cash flow, invest the limited funds into other priority investment areas.

Enhance competitiveness through implementing energy conservation, improving energy-saving efficiency, reducing energy costs and enhancing the quality of environment, establish green corporate image and enhance market competiveness.

- Q:The notebook power adapter flashes

- 1: Check the socket with a multimeter is normal, the supply voltage is 220V. If the utility voltage is not normal, it is recommended to replace the use of environmental testing. 2: Check with the multimeter whether the output voltage and current of the power adapter match the label. If the gap is very large, and the mains voltage is normal, you can determine the power adapter failure, need to replace the laptop power adapter. 3: If the above check is normal, remove the laptop battery, do not external adapter. Press and hold the notebook power button 5 seconds to repeat 3 times. After releasing the notebook residual charge, insert the power adapter separately, power on the test. 4: If the fault persists, check the notebook's power connector, whether the exception. Such as loose or the appearance of damage and so on. 5: the above checks are normal, basically can be a preliminary judgment is the notebook motherboard failure. Recommended repair service station.

- Q:ASUS power adapter Acer can use it

- See whether the power adapter is suitable for notebook use, the following three conditions for reference: 1. The output voltage of the adapter is the same as that of the notebook.

- Q:The laptop power adapter is hot

- My point of view: First: your laptop power supply in a small ventilation environment, resulting in poor heat dissipation, Second: the life of the power supply is 3-5 years, the gradual oxidation of electronic components and some of the aging components, resulting in no load and load a lot of power, Third: the battery close to each run, and then connected to the power, the power to the battery charger and notebook power supply, so the pressure is not hot strange.

- Q:How to disassemble the notebook power adapter

- 3, then open the shell of the power adapter, you can see the adapter circuit outside the package with a copper shield, with a knife to cut the shielding tape on the tape, and then use the soldering iron shield and the internal circuit board connected to the two Solder joints, you can remove the shield.

- Q:Oil-free vertical vacuum pump why a little negative pressure inverter on the torque limit

- Here is not the inverter can solve the problem, you should first 220V single-phase AC rectifier for the DC (full-wave rectifier plus filter about 310 volts),

- Q:What is the IGBT? Our inverter IGBT fried,

- Popular point is a switch, give him the signal to continue in accordance with a certain order switch, the DC through the switch into a change in the exchange of alternating current, different frequency.

- Q:Do you want to pay attention to the number of poles of the motor when selecting the inverter?

- Inverter selection is mainly to see the power, and then pay attention to voltage problems. Finally look at what your motor is carrying.

- Q:What is the frequency of `30 points

- Frequency is to change the frequency ah, see what you are variable frequency equipment.

- Q:Motor nameplate on the standard 2P, I set the number of motor pole in the inverter, is set 2 or 4 pole?

- 1,2P refers to the number of motor poles, so it is certainly even 2, if the inverter is set to determine the number of motor poles, please write 2P value, if 2P = 4, please write 4 3, look at the nameplate on the motor rated speed for how much, you can confirm the number of motor poles. (N = 60f / p) P: pole pairs

- Q:What are the AC motor speed control methods? What are the characteristics of each

- 1, the frequency converter: smooth, according to the need to adjust the speed, is the future direction of the development of AC motor; (FM) 2, star, triangular connection conversion, generally in the larger motor start star start, triangular operation, Starting current. (Magnetic pole pairs) 3, there is a two-speed, three-speed motor, an increase of the winding, the main change in the stator winding connection to change the speed. (Change the number of pole pairs) The speed of change has two factors: magnetic pole logarithm, frequency

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

High Medium Voltage Drive 3KV 10000KW VFD

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords