High&Low Chrome Alloyed Cast Grinding Balls(ISO9001:2008) in Top Quality and Good Hardness

- Loading Port:

- Qingdao Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25M.T. m.t.

- Supply Capability:

- 200000M.T./Year m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Chemical composition of High&Low Chrome Alloyed Cast Grinding Balls(ISO9001:2008) in Top Quality and Good Hardness

Item | C | Cr | Si | Mn | S | P | Cu | Mo | Ni | Hardness |

Element | 0.6-1.2% | ≤ 1.0 | 0.15-0.6 | 0.6-1.5 | ≤ 0.04 | ≤0.04 | ≤0.1 | ≤0.25 | ≤0.1 | 55-65 |

2.Specification and Hardness of High&Low Chrome Alloyed Cast Grinding Balls(ISO9001:2008) in Top Quality and Good Hardness

Nominal diameter (mm) | Diameteical tolerance (mm) | Weight of Single of forging ball in average | Number of piece of One ton forging ball in average | Surface hardness | Impact toughness |

DIA 20 DIA 25 DIA 30 DIA 40 DIA 50 |

+2 -1 | 32 64 110 263 513 | 31250 15625 9090 3802 1949 |

55-65 |

≥12 |

DIA 60 DIA 70 DIA 80 DIA 90 DIA 100 |

+3 -2 | 888 1410 2104 2996 4110

| 1126 709 475 333 243 | ||

DIA 110 DIA 120 DIA 130 | +4 -2 | 5457 7102 9030 | 182 140 110 | ||

DIA 140 DIA 150 | +4 -3 | 11278 13871 | 88 72 |

3.Applied Field of High&Low Chrome Alloyed Cast Grinding Balls(ISO9001:2008) in Top Quality and Good Hardness

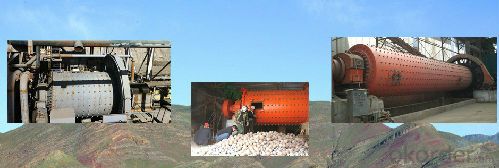

1) Power Plant, 2) Mineral Processing, 3) Refractory Factory, 4) Cement Plant

4.Packing Information of High&Low Chrome Alloyed Cast Grinding Balls(ISO9001:2008) in Top Quality and Good Hardness

Container Bags: 1000Kgs/Container Bag

Steel Drums: 850Kgs/Drum

- Q:Why does the precision casting factory not usually make iron castings?

- Jiangyin Lin Xing stainless steel (precision manufacturing) Co., Ltd. to provide professional precision casting

- Q:Is the cast steel a casting part?

- Cast steel is divided according to material, as well as cast iron parts, cast aluminum parts and so onCasting parts are divided according to the method, as well as forging partsCast steel parts must be casting parts

- Q:What are the factors affecting the machining process of the casting material and structure?

- The impact on the machining is obvious, it should be the material and heat treatment of the castingCarbon steel parts should be treated by heat treatment (annealing) without special conditions. It can effectively prevent the uneven hardness and hard points. It is easy to turn.

- Q:How to calculate the price of casting parts?

- According to the complexity of the workpiece, material and casting requirements and process yield

- Q:How to get rid of casting sand inside casting parts?

- Are you saying that in the sand casting cavity? We use the manual blast, he is like a pipe will be automatic shot out of the grit, into the casting cavity, to remove the internal cavity in the purpose of casting sand!

- Q:What is the casting material?

- Gray iron, carbon steel, low alloy steel, ductile iron, stainless steel, Aluminum Alloy can all be cast out

- Q:Can the casting part be phosphating with the phosphating solution of the pickling board?

- Like stainless steel casting, duplex stainless steel casting is phosphating, ductile iron gray iron is not required

- Q:Why should pig iron be used in casting?

- Not necessarily is iron, steel, stainless steel, aluminum, copper can be cast iron, is cheaper, and better properties of cast out, for example, is not easy to rust, high strength, easy processing and so on, and is the only iron iron cast out, it is not necessarily the raw pig iron, plus some other material

- Q:How do you mark it on the drawing? Do you need to discuss it with the manufacturer?Because the casting allowance is the standard, then, after all, is the theoretical value, the actual level depends on the manufacturer, so is it necessary to ask the manufacturer?

- The general foundry casting technology division will mark put shrinkage and the allowance of the map in your chart (usually with the red pen) for the production of wood or other material wood workers die drawings.

- Q:Which master knows how the casting tolerances for malleable iron, gray iron and ductile iron should be chosen? Hurry up, thank youCan you provide a tolerance scale for castings, please?

- Usually manual molding optional CT11 class, ordinary machine modeling optional CT10 class, high pressure molding should reach CT9 level. The tolerances on the wall thickness of the casting are comparable to those of other dimensions of the same casting.

1. Manufacturer Overview |

|

|---|---|

| Location | Shandong, China |

| Year Established | 2000 |

| Annual Output Value | Above US$100 Million |

| Main Markets | Africa; Mid East;South Asia;Southeast Asia;Eastern Asia;Southern Europe |

| Company Certifications | ISO9001;IS014001 Certificate |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Qingdao Port; Tianjin Port; Shanghai Port |

| Export Percentage | |

| No.of Employees in Trade Department | 6-10 People |

| Language Spoken: | English;Chinese; |

| b)Factory Information | |

| Factory Size: | Above 40,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | Grinding Ball; Grinding Rod; Cylpeb; Grinding Media; Ball Mill Ball |

| Product Price Range | Average |

Send your message to us

High&Low Chrome Alloyed Cast Grinding Balls(ISO9001:2008) in Top Quality and Good Hardness

- Loading Port:

- Qingdao Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25M.T. m.t.

- Supply Capability:

- 200000M.T./Year m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords