High Light Marble Stone Film Uesed For Decorative

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Application of High Light Marble Stone Decorative Film:

High Light Marble Stone Decorative Film can be applied on flat panel or walls easily, and if you want to change, you can tear it easily without damage your wall. Our High Light Marble Stone Decorative Film is very easy to install and eco friendly.Our High Light Marble Stone Decorative Film can be used on Furniture, kitchen wall, bedroom, hotel etc. many fields.

2.Main Features of the High Light Marble Stone Decorative Film:

Surface is smooth, exquisite

Water-proof, resistance to deformation

Environmental friendly

Different models and various kinds of style

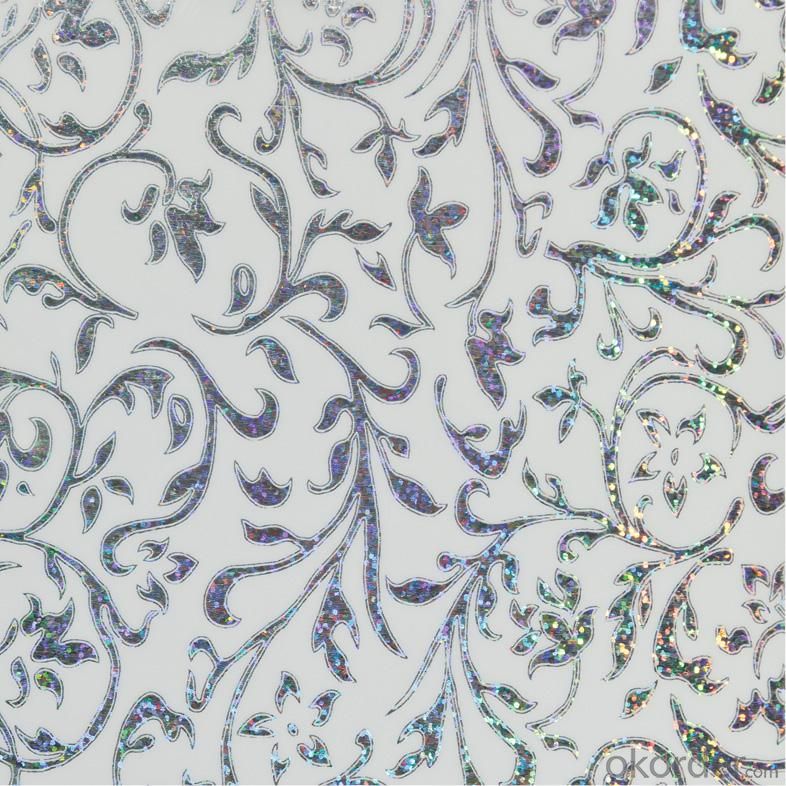

Sparkle silver and wood grains are available

Easy cleaning

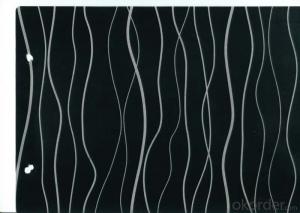

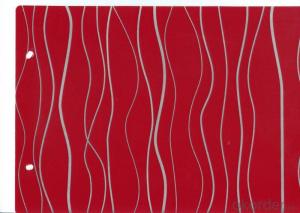

3. High Light Marble Stone Decorative Film Images:

4. High Light Marble Stone Decorative Film Specification:

Thickness : 0.10 - 0.50mm

Width : 1240/1260/1400 mm

Weight : 20-21 KGs / Carton

Length : Based on customer's requirement

5.FAQ of High Light Marble Stone Decorative Film:

We have organized several common questions for our clients,may help you sincerely:

① How about your company?

A world class manufacturer & supplier of PVC decorative sheet is a new kind of environmental protection material, it has strong sense of grain simulation, waterproof, acid and alkali resistant, fire from self quenching characteristics, because it will not fade, so the construction without paint, convenient operation, which shortens the construction period and reduce the cost, especially without paint pollution gas.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

- Q:Laser cutting mirror stainless steel, do not tear off protective film, OK? What's the effect?

- If it is an ordinary film, it can be torn off and attached to the laser special film. At present, most of the stainless steel plate on the market protection film for ordinary film, if it is laser cutting processing, it is recommended in order to plate when requiring manufacturers to stick laser special film. Laser film thickness is generally thicker, not easy to delimit wear, in addition, laser processing, the film will not be blown off, and always play a protective role.

- Q:Should the protective film of the sole of high-heeled shoes be torn off?

- Better tear it off.Protective film is smooth surface, no lines, no friction, prevent falling, shock absorption function

- Q:Is the laptop monitor covered with protective film?

- We know that the LCD protective film factory configuration is a layer of plastic film, and the film, not only greatly affect the visual effects, reduce the permeability and have a lot of reflection, will affect the user's eye. In addition, the heat dissipation of the display is extremely unfavorable. The plastic film is not a good conductor of heat. The liquid crystal panel will heat up after a period of time, and touch the panel with the back of the hand. You can tell that the temperature is very high. If the surface is coated with a protective film with poor thermal conductivity, it virtually prevents the cooling of the liquid crystal and even shortens the effective life of the display.

- Q:The mirror protective film is what, how should the truth!

- The common protective film just scratch the most basic function, mirror protective film protective film is a functional OK8 brand launched the first one in the scratch with new technology, the mobile phone background lights off when the protective film provides the user with a mirror function, as well as anti spy film, matte film, AR film other types of protective film, LZ if you want to further understand can go to the OK8's official website. There is this brand of protective film, the price is similar to the highest inside the protective film

- Q:What specifications about adhesion does PET protective film have?

- More specifically, you want to know how many degrees the adhesion of PE film can be further classified into, right?PE protective film can be devided into two types--based on static and based on glue. The static-based type is not adhesive. But as for the glue-based type, the adhesion can be further classified into degrees as follows: super low, low, ordinary, high,super high; or further classified using the unit G.

- Q:How to use tempered glass film? If I have coated the screen with tempered glass film, do I need to coat it with ordinary protective film?

- Clean the screen at first. Peel the layer marked by label No. 1 and put the film on screen. Make sure the film is aligned at the screen. Then press the central part of the film. The film will stick to the screen itself. And then peel the label No. 2. If you have used tempered film, there is no need to use ordinary film.

- Q:What kind of glue is suitable for protective film used in the decoration of entrance doors?

- There's a kind of appropriate film with big rolls. But it's very expensive. It's a little similar to the rolled protective film used on screen of mobile phone.

- Q:What kind of glue is used in PE protective film ?

- Both factice and glue are ok. It depends on what product you will use it on.

- Q:What material is used for the adhesive film of the protective film on the aluminum plate?

- The protective film on the aluminium plate is made of PE thin film. Specifically, the film is co-extruded by three layers of thin film. The film can be sticked to the aluminium plate to protect the surface of the aluminium plate from unexpected scratches and damage after it's covered with glue. If you want to learn more about PE protective film, you can go to the PP forum. There are many insiders who are specialized in this field.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

High Light Marble Stone Film Uesed For Decorative

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products