High-end Tunnel Steel Template

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

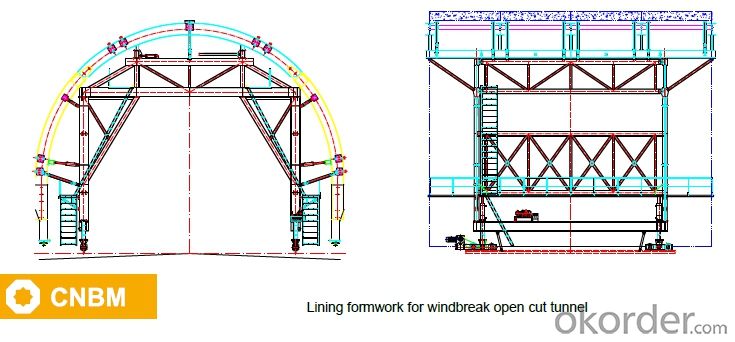

TUNNEL FORMWORK

The automatic hydraulic tunnel formwork is the equipment to make

the concrete lining for the tunnel in one time.The empty gantry allows the

transport vehicles to pass. The motor gearbox is adopted to drive

the whole equipment, the formwork is fully hydraulic, with hydraulic

cylinder to prop & strip, and lock mechanically

Advantage

◆ Good concreting quality

◆ High-speed of installation and removal of the form

◆ Easy operation and safety

- Q:What is the simple calculation method of the tunnel excavation unit price

- Comprehensive unit price = labor cost + material equipment fee + mechanical + management fee + profit

- Q:What is the first project of tunnel constructionNow to do some of the tunnel program, you need to be the first to list out, a total of what? I know that the first branch, two lining, inverted arch, tunnel, pavement these

- The first project of concrete lining of this section as I bid the tunnel project, on the next two plays a role model leading lining construction, so the various factors must be considered in detail, before the construction plan, reasonable arrangement, strict control of construction process, construction timely summary, finally reached the first the United States, the project entity information is true and complete, the project finished good target

- Q:Loess tunnel construction quality control points

- 2) the invert, invert the filling layer and dry concrete construction should be concrete accurately, use the template, mechanical tamping compaction. The inverted arch concrete by pumping casting, should use the arch template ensure molding size meets design requirements. The construction of invert arch and filling layer should be completed according to the design of inverted arch concrete construction, the appropriate interval, and then change the proportion of concrete, filling layer of concrete construction;The construction of inverted arch and the cracks and deformation joints should be waterproof treatment according to design requirements, should be in accordance with the relevant provisions of this guide.Invert the overbreak in the allowable range, should be used with the same strength grade of concrete lining casting; overbreak exceeds, should according to the requirements of design and specification of the backfill, shall not use the random hole slag backfill, non intrusive rubble arch section.

- Q:Two tunnel lining reinforced concrete template to price behavior can be contracted

- Specific price mainly depends on the length of the tunnel, which is the size of the project, and the geological conditions of tunnel is the tunnel construction is now the price of pure artificial price, the specific price or to the bidding price and the construction unit price guide, after all, the project is now basically is the lowest bid, the inevitable choice to compress all fees is the construction unit.If you need to complete the tunnel labor contract price and the cost of all, you can continue to ask questions, hope to adopt!

- Q:Design of lining concrete is C30, what should be used in the construction of concrete arch cushion concrete?

- The thickness of the cushion should not be less than 70mm, and the concrete strength grade should not be less than C10;

- Q:What are the reasons for the two lining concrete lining of the tunnel?

- (4) improper concrete mix, segregation, depending on the template part of the lack of slurry or template serious leakage;(5) no watering wood template wet, water bonding or early form removal, Chaimo missing edge off angle, resulting in reinforcement.

- Q:I would like to ask the tunnel hydraulic trolley steel template design is the use of what software

- You are talking about the design of the tunnel two lining car software.

- Q:I would like to ask the tunnel step method excavation, the height of each step is how to divide?

- Tunnel excavation adopts mechanical construction, tunnel excavation using simple self assembling drilling trolley, millisecond detonator, in order to improve the effect of smooth blasting around the eyes, around the eye using special Nonel detonation. Tunnel outlet using muck loader, dump truck with transport ballast. Two tunnel lining concrete use of the length of integral pouring formwork trolley 12M, concrete mixing station in centralized mixing, concrete transport vehicle transport pump into the mold.

- Q:I would like to ask the high-speed rail tunnel invert small side wall and arch with the small side of the wall of the hanging formwork of what a good method?

- Die casting. Install the inverted L hanger on the side wall.

- Q:What is the width of a ring in a tunnel

- Generally used in the tunnel as a two car lining template

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

High-end Tunnel Steel Template

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

New products

Hot products

Related keywords