High-end Steel Structure

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Steel Structure

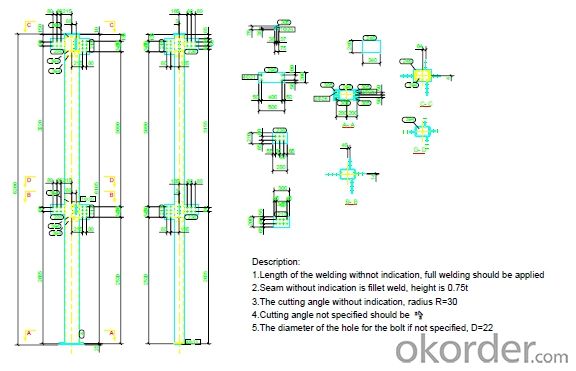

Description:

1.Length of the welding withnot indication,full welding should be applied

2.Seam without indication is fillet weld,height is 0.75t

3.The cutting angle without indication,radius R=30

4.Cutting angle not specified should be 20/20

5.The diameter of the hole for the bolt if not specified, D=22

Project Reference:

The new railway section of bullet train is the inspection and repair base for north China and

the inspection and repair center for the north section of Beijing to Shanghai high-speed

railway. The total area is 183,330 square meters. The steel structure adopt arch steel truss

with maximum span 36 meters.

- Q:Can steel structures be designed to be earthquake-resistant?

- Yes, steel structures can be designed to be earthquake-resistant. Steel is a strong and flexible material that is capable of withstanding seismic forces. By using innovative design techniques and incorporating features such as dampers and bracing systems, steel structures can be engineered to absorb and dissipate the energy generated during an earthquake, minimizing damage and ensuring the safety of occupants.

- Q:What is the role of structural engineers in designing steel structures?

- Structural engineers play a crucial role in designing steel structures by analyzing and designing the structural framework to ensure its safety, stability, and durability. They consider various factors such as the load-bearing capacity, wind and seismic forces, and architectural requirements to create efficient and cost-effective designs. Additionally, they collaborate with architects, contractors, and other professionals to ensure the structural integrity of the steel structures throughout the design and construction process.

- Q:What is the role of steel canopies in a structure?

- Steel canopies play a crucial role in providing protection and enhancing the aesthetic appeal of a structure. They serve as a protective covering, shielding the building and its occupants from various weather elements such as rain, sun, and snow. Additionally, steel canopies can also act as architectural features, adding a visually pleasing element to the overall design of a structure.

- Q:What are the different types of steel coatings used in structures?

- There are several different types of steel coatings that are commonly used in structures for various purposes. Some of the most common types include: 1. Galvanized Coating: This is one of the most widely used steel coatings, which involves applying a layer of zinc to the surface of the steel. Galvanized coatings provide excellent corrosion resistance and protect the steel from rust and other forms of degradation. It is often used in outdoor structures and applications where the steel is exposed to moisture and harsh weather conditions. 2. Epoxy Coating: Epoxy coatings are applied to steel surfaces to provide protection against corrosion and chemical damage. These coatings are highly durable and resistant to abrasion, making them ideal for structures that are exposed to harsh industrial environments or chemical exposure. Epoxy coatings also provide a smooth and attractive finish to the steel surface. 3. Powder Coating: Powder coating is a dry finishing process that involves applying a layer of finely ground particles onto the steel surface. The powder is electrostatically charged and then cured under heat, creating a hard, durable, and smooth coating. Powder coatings provide excellent resistance to corrosion, UV rays, and chemicals, making them suitable for both indoor and outdoor structures. 4. Polyurethane Coating: Polyurethane coatings are typically used in structures where aesthetics and durability are important. These coatings provide excellent resistance to weathering, UV rays, and abrasion, making them suitable for exterior structures such as bridges, stadiums, and architectural facades. Polyurethane coatings also offer a wide range of colors and finishes, allowing for customized designs. 5. Thermal Spray Coating: Thermal spray coatings involve applying a layer of molten or heated material onto the steel surface using a spray gun. These coatings can be made of various materials such as metals, ceramics, or polymers, depending on the desired properties. Thermal spray coatings are used to enhance the performance of steel structures by providing increased corrosion resistance, wear resistance, and thermal insulation. Overall, the choice of steel coating depends on the specific requirements of the structure and the environment it will be exposed to. Each type of coating has its own advantages and limitations, and careful consideration should be given to select the most appropriate one for optimal performance and longevity of the steel structure.

- Q:What are the different types of steel canopies used in construction?

- There are several types of steel canopies commonly used in construction, including cantilever canopies, retractable canopies, walkway canopies, and entrance canopies.

- Q:What is the role of steel in automotive manufacturing plants?

- The role of steel in automotive manufacturing plants is crucial as it serves as the primary material for building the structural components of vehicles. Steel is used in various forms, including sheets, beams, bars, and tubes, and it offers exceptional strength, durability, and versatility. One of the primary applications of steel in automotive manufacturing is in the body and chassis construction. Steel's high tensile strength allows it to withstand the forces and impacts that a vehicle may encounter during its lifespan. It provides rigidity and structural integrity to the vehicle, ensuring passenger safety in the event of a collision or rollover. Steel is also used extensively in the manufacturing of engine components, such as crankshafts, connecting rods, and cylinder heads. These parts require high strength and heat resistance, which steel can provide. Additionally, steel is used in the production of suspension systems, brake components, and exhaust systems, where its strength and resistance to corrosion are highly valued. Furthermore, steel plays a vital role in the manufacturing of automotive body panels. It is often used for outer panels like doors, hoods, and roofs due to its ability to be shaped into complex forms and its resistance to dents and scratches. Steel's malleability allows manufacturers to create aesthetically appealing designs while maintaining the necessary safety standards. Moreover, the use of steel in automotive manufacturing plants offers economic benefits. Steel is widely available, relatively inexpensive, and can be easily recycled, making it a sustainable choice. Its widespread use also allows for efficient mass production, reducing manufacturing costs and ultimately making vehicles more affordable for consumers. In conclusion, steel is an indispensable material in automotive manufacturing plants. Its strength, durability, versatility, and cost-effectiveness make it an ideal choice for building the structural components of vehicles, ensuring safety, performance, and aesthetic appeal.

- Q:How are steel structures designed to accommodate security and surveillance systems?

- Steel structures can be designed to accommodate security and surveillance systems in several ways. Firstly, the structural design can include provisions for the installation of surveillance cameras and other security equipment. This may involve incorporating mounting brackets or fixing points into the steel framework, ensuring that the cameras can be securely attached to the structure. Additionally, the design can include pathways or conduits within the steel framework to accommodate the necessary wiring and cables for these systems. Furthermore, steel structures can be designed to support the weight of security equipment such as access control systems, alarms, and sensors. The strength and load-bearing capacity of steel make it ideal for supporting heavy and robust security devices. Designers can calculate and reinforce the structure to ensure that it can handle the additional weight and stress imposed by these systems. Moreover, steel structures can also be designed with security in mind by incorporating features such as reinforced doors, windows, and access points. These elements can be made from steel or reinforced with steel components to enhance their resistance to break-ins and unauthorized access. The structural design can also include measures to prevent tampering with the security systems, such as concealing wiring and equipment within the steel framework or using protective enclosures. Lastly, steel structures offer the advantage of flexibility and adaptability. They can be easily modified or expanded to accommodate future security needs. For example, if there is a need to install additional surveillance cameras or upgrade the security system, the steel structure can be easily adapted to incorporate these changes without compromising its integrity. In conclusion, steel structures can be specifically designed to accommodate security and surveillance systems by incorporating mounting brackets, pathways for wiring, and provisions for heavy equipment. They can also be reinforced to support the weight and stress of security devices and incorporate features to enhance security, such as reinforced doors and windows. Additionally, steel structures offer flexibility for future modifications and upgrades to the security system.

- Q:How are steel sports facilities constructed?

- Steel sports facilities are typically constructed using a combination of prefabricated steel components and on-site assembly. The process involves designing the structure, fabricating the steel components off-site, transporting them to the construction site, and then erecting and assembling the steel framework. This method offers several advantages, including speed of construction, cost-efficiency, and durability, making it a popular choice for sports facility construction.

- Q:What is the role of steel in environmental and sustainable buildings?

- The significance of steel in environmental and sustainable buildings cannot be overstated. Its numerous benefits and properties play a crucial role in these types of structures. To begin with, steel is an incredibly durable and long-lasting material. This reduces the need for frequent maintenance and repairs, which in turn minimizes waste generation and the consumption of resources over time. Additionally, steel is 100% recyclable, making it an excellent choice for construction. When a steel building reaches the end of its life cycle, the steel can be easily recycled and repurposed. This reduces the demand for new steel production and minimizes the carbon footprint associated with manufacturing. Moreover, recycling steel requires significantly less energy compared to producing new steel, resulting in energy savings. Furthermore, steel is lightweight, allowing for more efficient transportation and reducing carbon emissions during construction. The use of steel frame systems also enables flexible and open designs that optimize space utilization and allow for future modifications or expansions without major structural changes or demolition. Steel is also highly resistant to fire, earthquakes, and extreme weather conditions, providing a safe and resilient structure. This durability reduces the need for reconstruction or repairs, thus minimizing the environmental impact caused by these activities. Additionally, steel can contribute to energy efficiency in buildings. It can be used in the construction of energy-efficient roofs, walls, and windows, which help reduce heat transfer and improve insulation. This leads to lower energy consumption and greenhouse gas emissions for heating and cooling purposes. In conclusion, the role of steel in environmental and sustainable buildings cannot be underestimated. Its durability, recyclability, lightweight nature, and energy-efficient properties make it an ideal material for constructing environmentally friendly and sustainable structures. By choosing steel, we can contribute to reducing waste generation, conserving resources, minimizing carbon emissions, and creating resilient and energy-efficient buildings.

- Q:What is the role of steel canopies in a structure?

- Steel canopies play a crucial role in providing protection and enhancing the aesthetic appeal of a structure. They serve as a protective covering, shielding the building and its occupants from various weather elements such as rain, sun, and snow. Additionally, steel canopies can also act as architectural features, adding a visually pleasing element to the overall design of a structure.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

High-end Steel Structure

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords