High-end Steel Structure Used in Construction

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Steel Structure

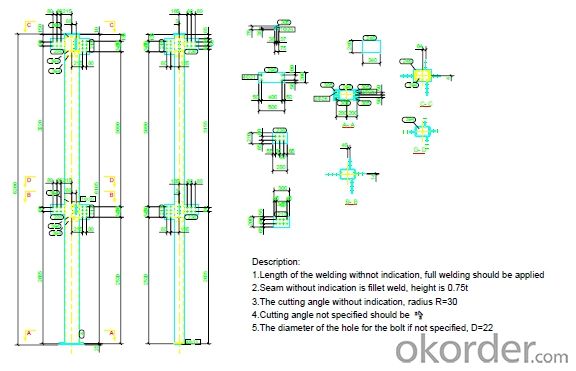

Description:

1.Length of the welding withnot indication,full welding should be applied

2.Seam without indication is fillet weld,height is 0.75t

3.The cutting angle without indication,radius R=30

4.Cutting angle not specified should be 20/20

5.The diameter of the hole for the bolt if not specified, D=22

Project Reference:

The new railway section of bullet train is the inspection and repair base for north China and

the inspection and repair center for the north section of Beijing to Shanghai high-speed

railway. The total area is 183,330 square meters. The steel structure adopt arch steel truss

with maximum span 36 meters.

- Q:What are the fire safety considerations for steel structures?

- Some fire safety considerations for steel structures include the use of fire-resistant coatings, the implementation of proper fire detection and suppression systems, the inclusion of fire barriers to prevent the spread of flames, and the incorporation of adequate evacuation routes and emergency exits. Additionally, ensuring proper maintenance and regular inspections of the steel structure to identify any potential fire hazards is crucial.

- Q:What are the different types of steel roof systems used in building structures?

- Building structures commonly utilize various types of steel roof systems. Some of the most popular options include the following: 1. Standing seam roofs display vertical panels that interlock with each other. These roofs have raised seams that create a sleek and modern appearance. They are renowned for their durability, ability to withstand harsh weather conditions, and minimal maintenance needs. 2. Corrugated metal roofs consist of sheets with repetitive ridges and valleys, resulting in a wavy pattern. They are lightweight, easy to install, and offer excellent protection against severe weather. These roofs are often found in industrial and agricultural buildings. 3. Ribbed metal roofs feature horizontal raised ridges across the sheets, which enhance the roof's structural integrity, making it more resistant to impacts and increasing its load-bearing capacity. They are commonly used in commercial and residential buildings. 4. Architectural metal roofs provide a wide range of design and appearance options. They can imitate the look of other materials, such as wood or tile, while maintaining the strength and durability of steel. These roofs are popular in upscale residential and commercial projects. 5. Metal shingle roofs consist of individual pieces that are installed similarly to traditional asphalt shingles. They come in various shapes and sizes, allowing for diverse aesthetic choices. Metal shingle roofs offer the longevity and resistance to fire and pests associated with steel, while providing a more traditional appearance. It's important to consider specific building requirements, such as size, architectural style, climate, and budget, when selecting a steel roof system. Seeking guidance from a professional contractor or architect can be beneficial in determining the most suitable option for a particular structure.

- Q:How is steel manufactured and processed for use in construction?

- Steel is manufactured through a process called steelmaking, which involves melting iron ore in a blast furnace with coke and limestone. This creates molten iron, which is then refined and converted into steel by removing impurities. The steel is then formed into various shapes such as beams, bars, or sheets through processes like rolling, forging, or casting. These steel products are then used in construction for applications such as building frameworks, bridges, and infrastructure due to its strength, durability, and versatility.

- Q:How are steel structures used in the construction of warehouses and storage facilities?

- Steel structures are commonly used in the construction of warehouses and storage facilities due to their strength, durability, and cost-effectiveness. Steel frames provide the necessary support for large open spaces, allowing for efficient storage and easy movement of goods. Additionally, steel structures can be easily customized and expanded, accommodating the changing needs of the facility. Overall, steel structures offer a reliable and flexible solution for constructing warehouses and storage facilities.

- Q:How are steel structures designed for resisting earthquake-induced ground settlements?

- To resist ground settlements caused by earthquakes, steel structures are engineered with specific design considerations and techniques. The main objective is to guarantee the structure's ability to withstand the potentially destructive effects of ground settlements during seismic events. Flexibility is a key factor in the design process. By allowing the steel structure to flex and deform in response to seismic forces, it can effectively absorb and distribute the energy produced by ground settlements. This is accomplished by using ductile materials and carefully calculating the connections between steel members. Furthermore, the structural design incorporates seismic-resistant systems, such as base isolation or energy dissipation devices. Base isolation involves placing the structure on flexible bearings or isolators, which separates it from the ground and minimizes the transmission of ground settlements to the building. Energy dissipation devices, such as dampers or braces, are also installed to absorb and dissipate seismic energy, further lessening the impact of ground settlements. In addition, steel structures are designed with redundancy and robustness in mind. Multiple load paths and redundant elements ensure that even if one part of the structure is affected by ground settlements, the overall stability of the building remains intact. This allows the structure to endure localized settlements without compromising its overall integrity. Advanced computational models and simulation techniques play a crucial role in the design process. These models take into account factors such as anticipated ground motion, soil properties, and the specific characteristics of the steel members and connections. By analyzing the structure's response to various ground settlement scenarios, engineers can optimize the design to enhance its seismic performance. Overall, the design of steel structures to resist earthquake-induced ground settlements involves a combination of flexibility, seismic-resistant systems, redundancy, and robustness. These design considerations, along with the utilization of advanced analysis techniques, ensure that the structure is capable of withstanding the dynamic forces generated by ground movements during an earthquake.

- Q:What are the guidelines for the fabrication and welding of steel structural members?

- The guidelines for the fabrication and welding of steel structural members include ensuring proper material selection, following design specifications and codes, maintaining cleanliness and integrity of the materials, employing qualified welders, conducting quality checks and inspections, and adhering to proper welding techniques and procedures. Additionally, it is essential to consider factors such as joint preparation, preheating, welding consumables, heat treatment, and post-welding processes to ensure the strength, durability, and safety of the steel structural members.

- Q:What is the material in the steel structure?

- Steel structure is mainly made of steel material, and it is one of the main types of building structure.

- Q:What are the design considerations for steel roofs?

- When designing steel roofs, there are several key considerations that need to be taken into account: 1. Structural Integrity: Steel roofs must be designed to withstand various loads, including the weight of the roof itself, snow loads, wind loads, and any other potential loads such as equipment or foot traffic. The design should ensure that the roof structure remains stable and can support these loads without compromising its integrity. 2. Waterproofing: Steel roofs must be designed to be watertight to prevent leaks and water damage. Proper installation of flashing, sealants, and other waterproofing measures is essential to ensure that the roof remains water-resistant. 3. Thermal Expansion: Steel expands and contracts with changes in temperature, so the design should account for thermal expansion to prevent buckling or warping of the roof panels. Proper provision for expansion joints or other methods of accommodating thermal movement should be incorporated into the design. 4. Fire Resistance: Steel roofs should be designed to be fire-resistant to minimize the risk of spreading fires. This can be achieved by using fire-resistant coatings or materials and ensuring that the roof design meets relevant fire safety regulations. 5. Ventilation: Proper ventilation is crucial for steel roofs to prevent the buildup of heat and moisture within the roof system. Adequate ventilation can help to reduce the risk of condensation, which can cause corrosion and other issues. The design should include provisions for proper ventilation, such as ridge vents or other ventilation systems. 6. Aesthetics: The design of steel roofs should also consider the desired aesthetics of the building. Steel roofs come in a variety of colors, finishes, and profiles, and the design should take into account the desired appearance and architectural style of the building. 7. Durability and Maintenance: Steel roofs should be designed to be durable and require minimal maintenance. The design should consider factors such as the choice of high-quality materials, proper installation techniques, and ease of access for maintenance purposes. By considering these design considerations, architects and engineers can create steel roofs that are structurally sound, weather-resistant, fire-resistant, aesthetically pleasing, and long-lasting.

- Q:How do steel structures perform in terms of resistance to seismic events?

- Steel structures generally perform well in terms of resistance to seismic events. Due to their high strength-to-weight ratio and ductility, steel frames can absorb and dissipate seismic energy effectively, reducing the risk of structural failure during earthquakes. Steel's flexibility allows the structure to sway and deform under seismic forces, thus minimizing damage. Additionally, steel structures can be designed and reinforced to meet specific seismic design criteria, further enhancing their performance and ensuring the safety of occupants.

- Q:What are the different methods of welding used in steel structures?

- There are several different methods of welding used in steel structures, including shielded metal arc welding (SMAW), gas metal arc welding (GMAW), flux-cored arc welding (FCAW), submerged arc welding (SAW), and laser beam welding (LBW). Each method has its own advantages and is chosen based on the specific requirements of the project, such as the thickness of the steel, joint configuration, and desired weld quality.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

High-end Steel Structure Used in Construction

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords