high efficiency jaw crusher used for mineral PE 900*1200

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 1 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

Jaw stone crusher machine:

1.ISO9001:2000

2.Price:negotiable

3.Capacity:5-800T/H

4.Payment terms:L/C or T/T

Jaw stone crusher machine:

1.ISO9001:2000

2.Price:negotiable

3.Capacity:5-800T/H

4.Payment terms:L/C or T/T

Jaw Crusher Description

The jaw crusher we offers are ideal for primary and secondary crushing. Jaw Crusher is one of the main types of primary crushers in a mine or ore crushing process plant and also is one of the most widely used crushing equipments in mining industry.We are famous jaw crusher manufacturers in China, and sold crusher machines to all over the world. This series of jaw crusher can reach the crushing ratio of 4-6 and the shape of final product is even. Because it is primary crusher, Jaw crusher is designed for long life service with minimum maintenance for hard, tough, abrasive material and overload high capacity

Jaw Crusher Working Principle

Primary jaw crusher is typically of the square opening design, and secondary jaw crusher is of the rectangular opening design. Jaw Crusher reduces large size rocks or ore by placing the rock into compression. A fixed jaw board, mounted in a "V" alignment is the stationary breaking surface, while the movable jaw exerts force on the rock by forcing it against the stationary plate. The space at the bottom of the "V" aligned jaw plates decide the crusher product size gap, or the size of the crushed product from the jaw crusher. The rock remains in the jaw until it is small enough to pass through the gap at the bottom of the jaws.

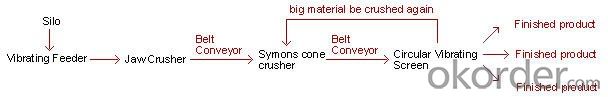

Brief introduction to stone crushing & screening plant

we manufactures various equipments for whole set of stone production line, and provide complete technical support for customers. The whole production line consists of Vibrating Feeder, Jaw Crusher, Impact Crusher, vibrating screen, Belt Conveyor, electric control cabinet and etc.

We design different production lines ranging 50 t/h to 500 t/h by combining different models of equipments.It is widely used for crushing hard limestone, granite, basalt, gravel, metallurgic slag, etc or artificial sand making for hydroelectric power, building material, high way, city construction, etc. Different models of equipments are combined to meet different customers' demands according to different craft requirements.

Process of stone crushing & screening plant

1. Big rocks are transported to the working site of stone production plant from quarry.

2. The rocks are transferred to primary crusher by vibrating feeder. Once there is a hopper prior to the vibrating feeder, the rocks are stored in the hopper firstly.

3. The crushed materials are transferred to Impact Crusher by Belt Conveyor for secondary crushing.

4. The materials are transferred to the vibrating screen, and screened into different sizes.

5. Those aggregate with suitable size will be transferred to the final product pile; while those with unsuitable size will be transferred to the Impact Crusher for re-crushing.

This forms a closed circuit manifold cycles. The sizes of final products will be graded and separated according to customers' requirements and application, and the deduster will be attached for the sake of environment protection.

Main advantages of stone crushing & screening plant

1. Customerized design

The production line is designed according to customer's requirement on the output size, types of output and capacity, as well as other factors such as material property, site conditions and purpose.

2. High efficiency and low cost

The arrangement of the machines in the production line can work efficiently and act for the maximum effect, which can ensure the efficiency and increase the output in unit time so that to lower the average cost of finished product (per ton).

3. Standard component

It is much convenien for replacement and maintenance of the machines. Shorten the shutdown time resulted from those maintenance.

4. Optimized production flow

The optimized production flow can ensure the capacity of the whole production line, the density of piling up and the shape of finished product, to satisfy the various purpose of product.

- Q:any suggestions, if you could, try and use #'s and/or both capital and lowercase leeters in you answer. i'm looking for something original.

- When i make usernames i don't look for anything original cause those are the ones that EVERYONE has. I like a distinguished name with character and no lowercase-capitals sequences. One that my personality relates to. One that people remember out of all the other names they would have seen that day, I dont want one thats like --> ELiTESKEELsx2__Pwns-u I want something corny, something with flare, My name is Emanuel so my username would be something relevant. Dont pick something original its so overused, pick something distinguished! something that only you would have. ^^

- Q:The car was yellow I think. It was in a junk yard and they got it by a crane and put it in a crusher and it started talking and they opened the crusher up and the car started talking and came out. I really want to know the name of it it's been bugging me for like a year now. it's not speed buggy it's another cartoon.

- I do not ever remember seeing cursing as a sin in the bible. How do they justify cursing as a sin in the first place? (Oh, yeah. If they do not like it then it must be a sin, that's right.) Using god's name in vain and bearing false witness are both on the list of Commandments. But neither of them apply to cussing.

- Q:Should the crusher run or stop and refuel?

- In order to ensure the normal operation of the equipment, the equipment must be regularly lubricated according to the specifications. In order to ensure the safety of personnel, refueling must be stopped after the operation

- Q:What does the spike on the front of the roof on houses mean?

- Crusher Dust. Its just like deco but dark grey. Does the exact same job

- Q:Beats Studio 2.0 VS Skullcandy Crushers?

- NEITHER of those are good, sorry! Please do NOT waste ANY of your money on those, because Skullcandy breaks WAY TOO SOON and its sound is RUBBISH! Also, ALL Beats (Dr.Dre or not, fake or not, does not matter) are massively overhyped and overpriced FASHION TOYS marketed VERY aggressively for gullible people who either DO NOT CARE or do NOT KNOW a single thing about PROPER audio quality! TRULY REPUTABLE manufacturers such as Sennheiser, Shure, Grado, Denon, AKG, Bowers Wilkins, Bang Olufsen, Etymotic, Beyerdynamic and Audio-Technica have ALL been around for DECADES so they KNOW what PROPER audio quality is all about! Therefore, they do NOT need any lousy rappers nor other celebrity wannabes to boost their sales. Therefore, please don't lose yourself to ridiculous fashion, instead start bragging on KNOWLEDGE of what REAL quality is all about!

- Q:A very close friend that's of the opposite sex? I'm pretty sure she likes me, but I don't know if I'm just egotistic and it's him she likes since I'm normally with him when she's around. It's a little confusing and makes me wonder how much of the situation I'm making up in my imagination...

- Yes. The worst part is that he has that nasally, you might think he is gay, kind of voice and has already made it apparent that he won't let em talk to her if it's the last thing he does.

- Q:the other day i was talking to one of my friends from school. we were playing a truth or dare game and he asked who i liked. i said guess he said me? i said which answer will freak you out the least? he said it will freak me out if you lie, so i said yeah i like you. after that he started talking to me more and the next day he sat next to me in my writing class and started talking to me. he had no work done so he kept asking for help and then when i wouldnt help him he erased half my essay. he got it back obviously and i knew it was joke, so no feelings were hurt or papers ruined. Our computers are old so if you press the right code the screen will flip upside down. he kept doing this to my screen the whole class and he asked to look at the songs i write. but i want to know if he likes me. from this story does it sound like he likes me, or just wants to be friends? were both thirteen and he came out and said he didnt know who he likes so im lost for what to do

- yeah it sounds like he might like you. or maybe he likes that you like him and he wants to keep that going

- Q:A match that will never take place.But I am curious of the responses.Rick and Scott Steiner vs the Crusher and the Bruiser

- giant haystacks i think?

- Q:i heard this in a funny video on youtube on pranks

- A butt crusher is a Sexual act , a type of an exercise where the butt muscles r exercised and also a equipment made to crush cigarette butts

- Q:i happened to be on the same airplane with him the other day. wasnt he big about the same time that the crusher was around? btw...poor fella is in a wheelchair...but still wears a red white and blue bandana, and hands out signed autographs to anyone interested :)

- Yeah I remember him from the mid to late 70's

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

high efficiency jaw crusher used for mineral PE 900*1200

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 1 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords