high efficiency jaw crusher used for mineral PE 600*900

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 1 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

Jaw stone crusher machine:

1.ISO9001:2000

2.Price:negotiable

3.Capacity:5-800T/H

4.Payment terms:L/C or T/T

Jaw stone crusher machine:

1.ISO9001:2000

2.Price:negotiable

3.Capacity:5-800T/H

4.Payment terms:L/C or T/T

Jaw Crusher Description

The jaw crusher we offers are ideal for primary and secondary crushing. Jaw Crusher is one of the main types of primary crushers in a mine or ore crushing process plant and also is one of the most widely used crushing equipments in mining industry.We are famous jaw crusher manufacturers in China, and sold crusher machines to all over the world. This series of jaw crusher can reach the crushing ratio of 4-6 and the shape of final product is even. Because it is primary crusher, Jaw crusher is designed for long life service with minimum maintenance for hard, tough, abrasive material and overload high capacity

Jaw Crusher Working Principle

Primary jaw crusher is typically of the square opening design, and secondary jaw crusher is of the rectangular opening design. Jaw Crusher reduces large size rocks or ore by placing the rock into compression. A fixed jaw board, mounted in a "V" alignment is the stationary breaking surface, while the movable jaw exerts force on the rock by forcing it against the stationary plate. The space at the bottom of the "V" aligned jaw plates decide the crusher product size gap, or the size of the crushed product from the jaw crusher. The rock remains in the jaw until it is small enough to pass through the gap at the bottom of the jaws.

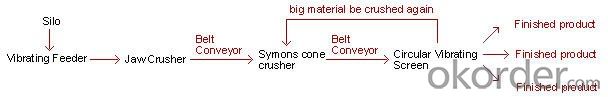

Brief introduction to stone crushing & screening plant

we manufactures various equipments for whole set of stone production line, and provide complete technical support for customers. The whole production line consists of Vibrating Feeder, Jaw Crusher, Impact Crusher, vibrating screen, Belt Conveyor, electric control cabinet and etc.

We design different production lines ranging 50 t/h to 500 t/h by combining different models of equipments.It is widely used for crushing hard limestone, granite, basalt, gravel, metallurgic slag, etc or artificial sand making for hydroelectric power, building material, high way, city construction, etc. Different models of equipments are combined to meet different customers' demands according to different craft requirements.

Process of stone crushing & screening plant

1. Big rocks are transported to the working site of stone production plant from quarry.

2. The rocks are transferred to primary crusher by vibrating feeder. Once there is a hopper prior to the vibrating feeder, the rocks are stored in the hopper firstly.

3. The crushed materials are transferred to Impact Crusher by Belt Conveyor for secondary crushing.

4. The materials are transferred to the vibrating screen, and screened into different sizes.

5. Those aggregate with suitable size will be transferred to the final product pile; while those with unsuitable size will be transferred to the Impact Crusher for re-crushing.

This forms a closed circuit manifold cycles. The sizes of final products will be graded and separated according to customers' requirements and application, and the deduster will be attached for the sake of environment protection.

Main advantages of stone crushing & screening plant

1. Customerized design

The production line is designed according to customer's requirement on the output size, types of output and capacity, as well as other factors such as material property, site conditions and purpose.

2. High efficiency and low cost

The arrangement of the machines in the production line can work efficiently and act for the maximum effect, which can ensure the efficiency and increase the output in unit time so that to lower the average cost of finished product (per ton).

3. Standard component

It is much convenien for replacement and maintenance of the machines. Shorten the shutdown time resulted from those maintenance.

4. Optimized production flow

The optimized production flow can ensure the capacity of the whole production line, the density of piling up and the shape of finished product, to satisfy the various purpose of product.

- Q:something in the house started sparking and started the house on fire and i saw my mom run out of the house so I run to my room grab a blanket and call my dogs and we run out of the house then the fire department shows up and distinguishes it. Then i look at the room and its a weird yellow brown color from the fire. Then we see this lady who wants to put flooring and stuff in my room. While outside I was telling my mom that my dad's stuff is ruined. then I see the bathroom and the counter top was cracked.

- Triceps Isolation means you are only working the triceps muscles. The other muscles of your body are not being worked. This can be done via triceps extensions. Another alternative is to do single arm triceps pull-downs. This exercise isolates the triceps muscles. Triceps kickbacks and triceps skull crushers will give you triceps isolation as well as long as you are performing them correctly. Hope this helps!

- Q:what is the serial Lock Folder 5.0?

- Yes cos i would rather get drowned than burnt as you would look deformed and even if you get caught in the fire..hey theres water!

- Q:id rather be crushed...cause i can handle my feelings.....it would be too hard to be the crusher, as you cant control THEIR emotions.how about you?

- I'd rather be the crusher. I've learned through past relationships to look out for number one. Not the best way to live, but I am a fool who wears her heart on her sleeve. It's not fun to let anyone else call the shots.

- Q:In my college History class, why did we learn about Muhammad, but not Jesus?

- History of Islam. Read your syllabus. EDIT: Seriously though, there's more evidence that Muhammad existed. There isn't one shred of credible evidence for Jesus. Now, read that carefully: I'm not saying any of the supernatural stuff is true, just that a guy most likely named Muhammad started preaching some imaginary god's words and spread his beliefs. There are actual, historical records backing-up Mo, none for Jesus. As far as true, physical, world history is concerned, it'd be a waste of time to worry about the j-man. Don't worry, no one has still proven that gods exist.

- Q:I got these Skull Crushers by snoop dogg today and i was listening to it and just when i put it in my pocket my music stopped playing. i pulled it out and saw where the metal part of the jack ends and becomes rubber it bends. its still connected to the cord but no sound. i need to find out a way to fix it or it would of been a waste of $85

- reset the mp3 player...(reboot)[turn off then on]

- Q:Does anyone know why Dr. Beverly Crusher left in season two of the show in the late 80s? i did not like the the actress that replaced mcfadden and im guessing the producers agreed since she came back the 3rd season

- Maurice Hurley, head writer and showrunner, did not like working with McFadden, and McFadden was fired at the end of the season 1. Diana Muldaur joined the production as the Enterprise's new chief medical officer, Dr. Katherine Pulaski, for season 2. Series creator Gene Roddenberry admitted that the Dr. Pulaski character did not develop a chemistry with the other characters, so McFadden was approached to return as Dr. Crusher for the third season. At first, she was hesitant, but after a phone call from co-star Patrick Stewart, McFadden was persuaded to reprise her role, which she subsequently retained through the remainder of the series. Wikipedia

- Q:Killing the majority of Americans is American now?

- Libs are by no means a majority... lol Democrat doesn't mean liberal, I voted for Obama in 08, and half of the Democrats that ran in my state. I did vote some Republicans, but I was independent. 5 years of LIEberal nonsense as landed me solidly back with the GOP.

- Q:It is a Frigidaire model.

- Shut it off, look for a jammed piece - remove what you have in there let it thaw if you cant get to it. Usually that's what happens to mine, it wont allow the roller to go back up that crushes the ice.

- Q:I have a crush on a guy who has a crush on a girl...and im NOT in highschool gt;.lt;anyway, hes liked her a long time and she totally knows it, she has a boyfriend that she has been with for a while and they SEEM really happy together, but this girl flirts with the guy who has a crush on her and leads him on all the time, Ive seen her do it IN FRONT of her boyfriend. This girl is just bad news and i want to help the guy who is so stuck on her, and make him realize if they were ever together, she would probably just be flirting with other guys in front of HIM. What kind of poison would be reccomended for disposing of her? (JK!)

- The best way for you to dispose of her is for you to dispose of him! Right now (it seems) you may be in the same boat as he, liking someone that has their eyes on someone else. Help yourself by focusing your attentions on finding someone who reciprocates your affections. By doing this one of two good things can happen, 1 he'll make a wise decision and focus on you or... ...2, you'll get lucky and find that someone Either way you'll be rid of her.

- Q:how far can I park from a fire hydrant in CA?

- They don't help much, especially if you have to buy much of what you burn. The reason is that when there's a fire, the chimney draws air up, and it not only draws the hot air from around the fire, it draws the warm air from the rest of the room and maybe the house too. You may feel warm when you're near the fire, but that's from radiant heat which heats objects and not the air. If you leave the chimney damper open when you don't have a fire burning, or if it doesn't close fully and many don't, the chimney will draw air from the house all the time, the air that you paid to heat with oil. I didn't realize how much this was true until I was up on my roof one summer day cleaning the chimney. The damper on my woodstove was mostly closed, but there was still enough draft coming up the chimney to ruffle my hair and blow soot into my face. The chimney was functioning as a chimney even though there was no fire in the stove. A woodstove or fireplace insert, on the other hand, keeps the amount of air going up the chimney under much better control, which means that not so much air is going up the chimney from your house, and also that you can control how fast the wood burns for best efficiency. An open fireplace burns too fast to get the maximum heat out of burning wood. And you never burn those prepared logs in a woodstove.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

high efficiency jaw crusher used for mineral PE 600*900

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 1 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products