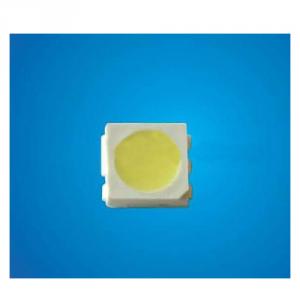

high efficiency 2835 light emitting diode LED

- Loading Port:

- Shekou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 4000 PCS

- Supply Capability:

- 1800000 PCS/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

1. Features & Benefits

- Package: 3.5*2.8*0.65mm (Top view white LED)

- Emitted Color: White

- Soldering methods: All SMT assembly methods

- Enables 3-, 4-, 5-step MacAdam ellipse kits

2. Typical Application:

- Bulb

- Indoor & Outdoor sign board back light

- Advertising backlighting

- General use.

3. Precautions for use

3.1 Soldering

SMD LED encapsulation is very flexible, outside force easily demolish radiant surface and plastic, As soldering , Please handle with care!

a. With No-clean Flux, according to reflow soldering cure condition when soldering, Reflow soldering should not be done more than two times, simultaneity you must insure clean on the radiant surface. Otherwise, foreign objects can affect radiant color.

b. Don’t process manual soldering except repair. Recommended to be soldered with 25W Anti-static iron, The temp. of the iron should be lower than 300℃ and soldering time should not be done more than three seconds, at the same time iron can’t touch radiant surface and plastic.

c. Don’t twist LED in course of manual soldering and experiment, Otherwise, the lights will not work possibly.

d. Please use the same BIN grade in one panel, and don’t mix the difference BIN grade in one panel when soldering. Otherwise, it will cause a serious uneven color problem.

e. Please control the sulfur content of solder paste and PCB.

f. Pb-free solder temp.-time profile as below:260℃Max.

3.2 Cleaning

a. Don’t be cleaned with ultrasonic. Recommended to be wiped with isopropyl alcohol or pure alcohol, wiping time should not be more than one minute. LED must be placed at room temperature for fifteen minutes before producing .you must insure clean on the radiant surface. Otherwise, foreign objects can affect radiant color.

b. LED can’t be in contact with acetate、trichloroethylene,acetone、sulfur、nitride、acid、alkali、salt.These matters can destroy LED.

3.3 Sealing

a. Sealing glue can’t contain sulfur,because these matter can affect fluorescence powder poisoning.

b. When using normal sealing glue, recommended will be operated life for 168hrs under normal temperature.

3.4 Storage

a. Don’t open the moisture proof bag before ready to use the LEDs.

b. The LEDs should be kept at 30℃ or less and 60%RH or less before opening the package. The max. period before opening the package is 1 year.

c. After opening the package, the LEDs should be kept at 30-35%RH or less, and it should be used within 3 days. If the LEDs should be kept at 30-35%RH or more, and it should be used within 4 hours.

d. If the LEDs be kept over the conditions of 20%, baking is required before mounting. Baking condition as below: 70±5℃ for 12 hours for bulk goods, 105±5℃ for 1 hours for roll goods.

e. The environment have no acid、alkali、corrosive gas、intensively shake and high magnetic field.

3.5 Static

a. Static and Peak surge voltage can destroy LED, Avoiding Instantaneous voltage when turn on or turn off the lights.

b. Please wear Anti-static wrist band、Anti-static glove、Anti-static shoes in the course of operation, and the equipment must be grounded.

c. After LED is be destroyed, leakage current increase obviously, and it will be forward voltage falling or failure lamp in the case of low current.

3.6 Test

a. Customer must apply the current limiting resistor in the circuit so as to drive the LEDs within the rated current. Otherwise slight voltage shift maybe will cause big current change and burn out will happen.

b. Also, caution should be taken not to overload the LEDs with instantaneous high voltage at the turning ON and OFF of the circuit.

c. The reverse voltage mustn’t exceed 5v when lighting on or testing the LED,otherwise, LEDs will be damaged.

3.7 Else

Radiant color of LEDs will be a little change with the current, recommended that LED is be used in series and resistance, when lighting, please don’t see directly radiant surface of LED, otherwise LED will burn eyes.

- Q:What does "1210" mean in patch LED?

- At present, most manufacturers of SMD light strip used by 3528 and 5050, and 3535 and 5630 in the majority, there are many of the 3528 and 5050 and 3535, such as patch LED used in automotive lighting.

- Q:Patch LED beads can be bought in what place?

- SMD LED lamp is now very popular, mainly because of long service life, but also rarely appear dead lights or dark, but there are many defects exist

- Q:Notes on patch LED

- Clean, do not use an unknown chemical liquid to clean the patch LED: an unknown chemical liquid may damage the patch LED. When necessary, immerse the patch LED in alcohol, less than 1 minutes at normal room temperature, and dry naturally for 15 minutes before starting to use

- Q:The ten patch LED lights are connected in parallel. The rated power is 5 watts. How much voltage do you need?

- Shunt split current series split voltageIs your single lamp voltage rated voltageIn addition to the red and green LED lights, the voltage is between 2 and 2.4, and the other colors are 3 to 3.6V

- Q:What is patch LED?

- LED lights, a common model, has 34654635285050 piranha.The most common assembly of lights and PCB boards is the DIP, that is, dual in line and SMT surface mount technology two.The 346546 is the LED with two positive and negative pins, which are inserted into the PCB board after cutting the foot;3528 and 5050 are a cube with 3 LED lights inside, known as the "three in one" LED lamp. It has no pin underneath, but has a metal patch that can be passed through the reflow soldering machine through the solder to the PCB board.General indoor LED screen with more patches, outdoor screen with more pins.

- Q:Patch LED light broken one, short circuit can use it?

- Patch LED lamp LED wick is usually series, and a bad, can temporarily short-circuit, temporary use, because after short-circuit, this LED wick voltage will be assessed to other LED wick, accelerate other LED wick aging.The damaged LED wick needs to be secured as soon as possible.

- Q:What is the difference between patch LED beads and LED beads: General

- A pin of the lamp, and outside a resin cap, because the reason LED beads can spotlight cap;There is no pin on the patch and there is no resin cap outside. Because of the lack of cap, the LED patch can not be concentrated.LED patch lamp is made of FPC circuit board, LED lamp and high quality silica gel sleeve. Waterproof performance, using low voltage DC power supply is safe and convenient, light colors, bright colors; outdoor use can be anti UV aging, yellowing, high temperature resistance and other advantages, the products are widely used in building lights, decorative lighting, advertising and entertainment quasi decorative lighting lighting field.

- Q:Indoor full color LED display module and LED what is the difference between a full color?

- The classification of the LED display according to the installation environment: indoor LED display screen, semi outdoor LED display, outdoor LED display; according to color: color LED screen, dual color LED display screen, LED display screen, the color LED display screen; according to the functional area can be divided into graphic screen, screen, screen, screen, digital dot matrix digital hybrid screen.

- Q:What is the difference in performance between the LED plug-in and the LED patch?

- The cooling of the plug-in is not good, because the plug-in's lamp foot, in order to save costs, generally use iron plus coating, heat conduction is not very good.The strength of aluminium alloy is not enough, it is easy to break, and copper is expensive.Relatively speaking, the patch is good, because the heat is welded on the PCB, copper or direct aluminum substrate cooling, patches near.Otherwise, why do high-power patch it?!SMT direct placement machine, a high degree of automation, low rate of bad.

- Q:LED light SMD LED package in what form, trouble you under the guidance of...

- Draw your own line, mm is replaced by mil on the line, with vernier caliper measurement, or know the model, count the number of mil. For example, 5050 is a close square with a width of 5.0mm*5.0mmInline LED (such as straw hat lights, 5mm), piranha LED, surface mount LEDSinglechip collection from hardware to software chm

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

high efficiency 2835 light emitting diode LED

- Loading Port:

- Shekou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 4000 PCS

- Supply Capability:

- 1800000 PCS/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords