High-effect MSG evaporation crystallization device

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 200 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1Company Information

FEICHENG JINTA MACHINERY CO., LTD.is the largest manufacturer of alcohol, fuel ethanol and DDGS high protein feed complete equipment in China which is capable to design, manufacture, install and adjust 3000t-500000t alcohol complete equipment in the turnkey project .

2.Product Description:

MSG evaporation crystallization device which we make is a high-efficient heat exchanging equipment used in alcohol, solvent, food ferment, pharmaceutical, petrochemical, refrigeration, organic chemistry, metallurgical industry, suitable for convection heat transfer of liquid to liquid,gas to gas, gas to liquid.

3.New Technology Description:

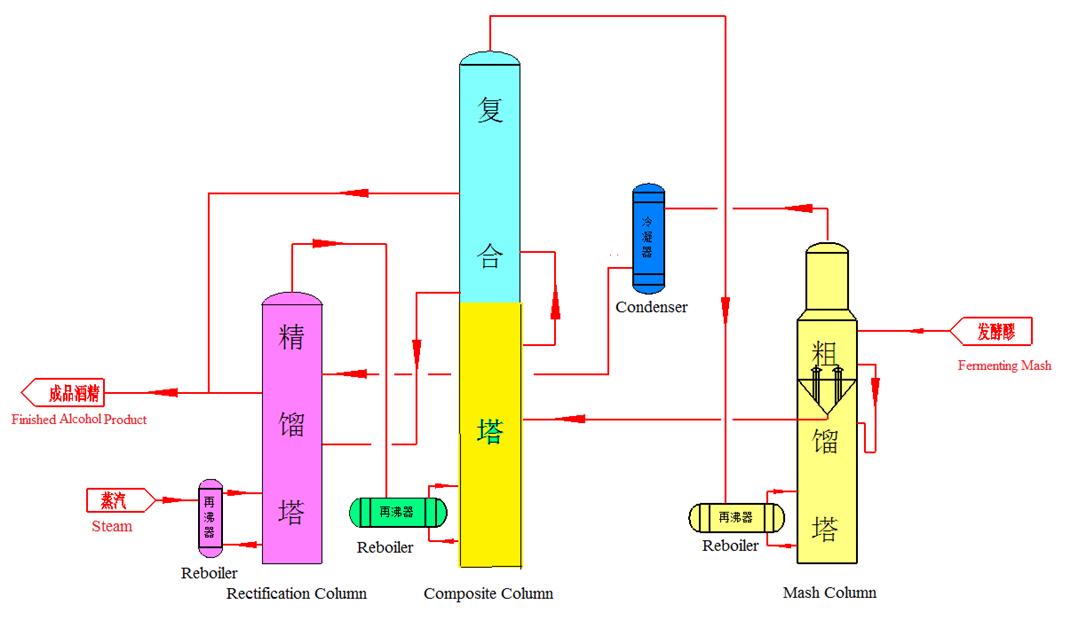

Five-Column Three-Effect Distillation Process

The key of this process is the heating methods,the steam heats one column directly and transfers the heat to other 4 columns to achieve three-effect thermal coupling and energy-saving effects.

Double-Mash-Column Three-Effect Distillation Process

The key of this process lies in the heating methods: the steam heats one column directly and transfers the heat to other 2 columns to achieve three-effect thermal coupling and energy-saving effects. The advantage of this process is energy-saving;it saves over 40% steam

4. Production Capability

1).Our company was established in the 1950s, designed and manufactured the first stainless steel distillation column in China, now We own advanced machining equipment and product testing equipment

1).Our company was established in the 1950s, designed and manufactured the first stainless steel distillation column in China, now We own advanced machining equipment and product testing equipment

2).Our company has 16 production workshops which can produce 6 full sets of equipment (including crushing section, liquefying saccharification section, fermentation section, distillation section and DDGS section) per month.

5. Designed capability

1). We own Design License of Special Equipment D1 & D2 Class; Manufacture License of Special Equipment A2 Class; Design License of Special Equipment GC Class.

1). We own Design License of Special Equipment D1 & D2 Class; Manufacture License of Special Equipment A2 Class; Design License of Special Equipment GC Class.

2).Our company achieves more than 20 patent certificates on distillation, DDGS, and other fields.

3).Our company owns ASME certification, ISO 9001 Quality System Certification, ISO 14001 Environmental Management System Certification & GB/T28001 Occupational Health and Safety Management System Certification

6.Contact us

Name:vick liang

Email:vick@jintagroup.com

Phone: 86 13953842508

Tel: 86-538-3393266

Fax: 86-538-3399066

Skype: vicklwk

QQ: 496443614

- Q:What is the principle of three-effect evaporator

- Due to the large pressure in the evaporative heat transfer chamber, the waste water is heated to overheat in the evaporative heat exchange chamber at a pressure higher than the normal liquid boiling point.

- Q:Why air conditioning indoor machine called evaporator components, outdoor unit called the condenser, I'd know that these two are heat exchanger,

- The difference is that the refrigerant in the evaporator is changed from liquid to gaseous, is an evaporative endothermic process, the pressure is generally low;

- Q:Refrigerator evaporator according to the structure of different types which are divided into four categories

- According to the structure classification: tube tube evaporator blown wire tube evaporator fin type evaporation material: aluminum (inflatable) aluminum tube, brass, steel pipe, copper and aluminum joints, iron pipe.

- Q:What are the advantages of embossed aluminum evaporator?

- The proportion of aluminum is relatively small, the production of equipment lighter weight; embossing can increase the heat transfer area, improve heat transfer efficiency.

- Q:What is the price of multi-effect evaporator?

- Qingdao Kang Jinghui energy-saving environmental protection company's good, cost-effective! Will be based on different liquid to make a different program!

- Q:Cooling capacity of 2000KW York cooler condenser, the evaporator is a pressure vessel? Please speak the standard. Thank you

- Condenser and evaporator is a static device, belonging to the category of heat exchangers, you can refer to GB150 GB151 and fixed pressure vessel safety technology inspection procedures

- Q:Audi q5 air conditioning evaporator in what place

- Hello; air conditioning evaporator inside the front face, that is in front of the tank! hope this helps!

- Q:Falling film evaporator how to choose the circulation pump

- Falling film evaporator using mechanical compressor two steam compression and then no conflict and pure hope to help

- Q:Is the heat of the refrigerant in the evaporator not becoming a high temperature gas?

- After the endotherm of the evaporator after the pressure and temperature are constant but become superheat working material is essentially absorbed the latent heat

- Q:What are the factors that affect the evaporative pressure of the central air conditioning evaporator? What is the normal value?

- Refrigeration about 0.5Mpa (this need to be based on the refrigerant model to determine, I am this is R22) heating about 2.8Mpa.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

High-effect MSG evaporation crystallization device

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 200 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords