HIGH-DURABLE PREPAINTED STEEL COIL FOR CHEMICAL ROOM

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50000 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Pre-painted Galvanized Steel Description:

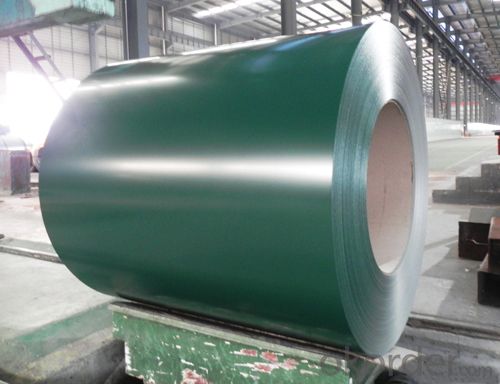

With GI as base metal, after pretreatment and liquid dope with several layers of color, then after firing and cooling, finally the late steel is called pre-painted galvanized steel which is good capable of decoration, molding, corrosion resistance.

2.Main Features of Pre-painted Galvanized Steel:

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent heat resistance performance

• High strength

• Good formability

• Good visual effect

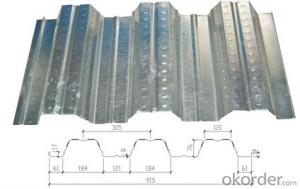

3. Pre-painted Galvanized Steel Images

4. Pre-painted Galvanized Steel Specification

Standard: JIS G3312 ASTM 755M, EN10169

Grade: CGCC,CS, DX51D

Thickness: 0.16mm~1.5mm,0.16-1.5mm

Width: 1250,600-1250mm

Coil weight:3-12 MT

Coil ID:508/610mm

Chemical composition:

C | Si | Mn | Cr | Ni | P | S |

0.150 | 0.476 | 11.231 | 12.50 | 0.900 | 0.039 | 0.010

|

5.FAQ of Steel

We have organized several common questions for our clients,may help you sincerely:

1.How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

2.How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

3. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

1.Structure of Pre-painted Galvanized Steel Description:

With GI as base metal, after pretreatment and liquid dope with several layers of color, then after firing and cooling, finally the late steel is called pre-painted galvanized steel which is good capable of decoration, molding, corrosion resistance.

2.Main Features of Pre-painted Galvanized Steel:

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent heat resistance performance

• High strength

• Good formability

• Good visual effect

3. Pre-painted Galvanized Steel Images

4. Pre-painted Galvanized Steel Specification

Standard: JIS G3312 ASTM 755M, EN10169

Grade: CGCC,CS, DX51D

Thickness: 0.16mm~1.5mm,0.16-1.5mm

Width: 1250,600-1250mm

Coil weight:3-12 MT

Coil ID:508/610mm

Chemical composition:

C | Si | Mn | Cr | Ni | P | S |

0.150 | 0.476 | 11.231 | 12.50 | 0.900 | 0.039 | 0.010

|

5.FAQ of Steel

We have organized several common questions for our clients,may help you sincerely:

1.How about your qality?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory.

2.How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;we can make sure 10 years life.

3. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

- Q:Health baby mother special plate which brand company production conditions are relatively high?

- New Zealand Zhige plate brand company has a good production conditions, the company has world-class product production conditions and production management level, for the market to provide covers, flooring, metal, lines, latex, the whole room customization of the whole Solutions; we have a wealth of market management experience and channel management capabilities for product distributors and end customers to provide comprehensive professional services.

- Q:2017 plate top ten brands

- China's top ten blockboard (Daixinban) brand 1 Bunny (China famous brand products, Daxin board joinery ten brands, Zhejiang famous brand, Huzhou City brand-name products, Dehua Group) 2 king coconut (well-known trademarks in China, China's top 500 brands, China's top ten brands of wood, the first Chinese woodworking board brand, Hangzhou King coconut holding) 3 Peng Hong (China famous brand, famous brand in Liaoning Province, Liaoning brand, China's wood-based panel industry leader, Dalian Peng Hong Wood) 4 Fuqing (China Famous Brand, Jiangsu Province, the famous brand, the top ten enterprises in China, Jiangsu Province, the largest plate enterprises, Jiangsu Fuqing set) 5 Hong Kong Pretty Beauty (international brand, plate aristocrat, China's first British art children's room for the board, the Asian brand 500, Hong Kong Pretty Beauty International set) Is one of China 's largest manufacturers of environmentally friendly decorative materials, is a collection research and development, students) 7 Fuhan (China Famous Brand, Hubei famous brand, well-known brands, China City, the industrialization of agriculture leading enterprises, Fu Han Wood Co., Ltd.) 8 years boat (China Famous Brand, Hangzhou famous brand, China's top ten brands, Zhejiang brand-name products, the Millennium Group Huahai Wood Co., Ltd.) 9 Hunan Wang (Huxiang Wang plate, China's well-known trademarks, China's top ten brands of plates, brand-name in Hunan, China's environmental labeling product certification) 10 Universal (Jiangsu Province, brand-name products, large-scale wood sheet processing and production enterprises, Nantong Fu Sheng Wood Co., Ltd.)

- Q:What are the harmful substances that man-made panels will release?

- Or the purchase of furniture used in the high-density fiberboard. These man-made sheet is the culprit leading to excessive indoor gas pollution. According to expert panel experts, the market of man-made sheet, the general use of urea-formaldehyde resin, in the use of the environment will release formaldehyde. And some poor quality, cheap big core board and other man-made sheet there is unreasonable use of plastic, so that the use of the release of a large number of formaldehyde, polluting the environment. ■ new house decoration must pay attention to the choice of decoration materials, try to use non-toxic and less toxic materials; preferably with green home improvement experience in the home improvement company construction, delivery requirements to provide indoor air quality testing report. ■ When buying furniture, pay attention to the formaldehyde and benzene release of furniture, the new furniture is best ventilation for some time, so that furniture in the release of harmful gases as soon as possible. ■ wood-based panel made of wardrobe must pay attention to, try not to underwear, pajamas on the inside. ■ fabric sofa should not only pay attention to the fabric, but also pay attention to the filler and the adhesive there is no pollutants. Can be used to reduce the indoor toxic gas effective air purification device, furniture to take some effective purification measures and materials, such as adsorption wardrobe in the adsorption of formaldehyde and so on.

- Q:What is the sheet of Sophia Wardrobe?

- What plate have ah, this is the best to buy a look at formaldehyde, the general furniture is formaldehyde weight, you can try Mu Tong's products, detection and management are good

- Q:Is it ok in the decoration? What are the materials used in general?

- See personal preferences. Compared to ready-made furniture, custom furniture has the following characteristics: Advantages: 1. Personalized strong, with the entire decoration style coordination, unity. 2. High space utilization. Disadvantages: 1. Scale, size is easy to grasp is not suitable for changing the placement, and is not easy to move adjustment. 2. price relative ????????????? Higher. 3. master crafts vary. Formaldehyde pollution. Woodworking scene to fight furniture: hand-based, mostly for the big core materials, plywood wood-based board. Plate custom furniture is mainly made of solid wood particle board, high density fiberboard, double-sided trihydrogenamine veneer, (environmental problems due to the state of wood-based panel products have mandatory environmental standards, the national standard to achieve E1 level. Some update faster manufacturers generally use The E0 level or even ultra-E0 level of the plate, the edge of the plastic is also used to plant as raw materials to ensure that environmental protection) non-standard production, and supporting the professional equipment.

- Q:TR90 memory board frame is what?

- In fact, there is no such frames, TR90 frame with the plate is different. 1, from the material comparison: TR90 frame is the use of nylon material (also known as nylon 12 or PA12), is the most popular ultra-light frame material, with light weight, good toughness, super safety and other characteristics, with super Flexibility, wear in motion will never break. (Except fake and shoddy products). Plate frame is the use of acetate fiber or propionic acid fiber. Injection molding or suppression of grinding production. 2, the process comparison: TR90 frame process complex, the injection of glass factory and spray paint process requirements are relatively high. Plate rack: Although the plate rack less painting, but in the work than the TR90 frame process to be much more, more complex process. 3, the use of comparison: TR90 Frame: light weight, comfortable to wear, more secure, more difficult to deformation. The only drawback is that it will fade. Plate frame: the same size of the frame relative to the TR90 frame will be more weight, the bridge of the nose will have the feeling of oppression, comfort is not as TR90 frame, flexibility and safety than the TR90 frame slightly worse. The advantages of three-dimensional sense of strong, three-dimensional edges and corners of the TR90 frame can not be compared, but also not out of color. )

- Q:Is the quality of the letter sheet?

- Did not hear this brand, only know the top ten brands of plates in the bunny, Moganshan, Yu Fu Lin, the Millennium boat, the king coconut, their product quality certainly no problem!

- Q:What conditions do you need? The The Its general 2-story cost is? The The Size needs to be the kind of foreign people to live !!! in Xi'an where to facilitate the purchase of materials? The The I need professional answers!

- Disadvantages: Wooden houses need to deal with anti-corrosion processes. In the earthquake, moisture, fire, insulation and other aspects of short board.

- Q:How to pick up the plate

- But it is very ugly the best not to find the goods sent to the consultation under the cheap point to give two

- Q:I ordered a wardrobe, the business I calculated 19 square meters, I always feel not so big, who can help me calculate it? Thank you!

- Almost, he is the case to expand the area calculation, is to put all the plates and then add together the area, I probably forget about 11.04 + 3.12 + 2.99 + internal classes

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

HIGH-DURABLE PREPAINTED STEEL COIL FOR CHEMICAL ROOM

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50000 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords