High Density SHP Grade Graphite Electrode with Nipples

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 1500 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Graphite Electrode Description

Topfly Material Co., Ltd.(Topfly Material) is a professional supplier of graphite products, which include graphite electrode, graphite block, graphite scrap, graphite powder and graphite parts. We have complete production lines, which include raw material mixing, forming line, baking line, impregnation equipment, graphitization line and machining and shaping line.

Graphite electrodes, widely used in steelmaking, non ferrous, foundry, casting, silicon industry. According to their level of quality, it can be divided into RP, HP and UHP grade. This item is for UHP grade graphite electrode. Resistivity: ≤6.0ohm, Bulk Density: ≥1.67g/cm3. Diameter is 350-650mm, length is 1800±100mm.

2.Main Features of the Graphite Electrode

(1) Pure quanlity, high carbon content.

(2) Competitive price, we have price advantage for HD grade graphite electrode.

(3) High density ≥1.67g/cm3 and low resistivity≤6.0ohm.

(4) Large quantity in stock, delivery time is within 25 days.

3.Graphite Electrode Images

More products for your reference:

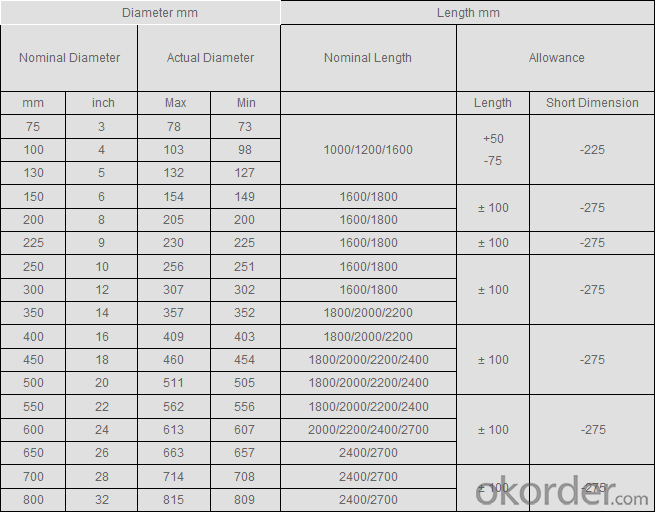

4.Graphite Electrode Specification

5.FAQ

We have organized several common questions for our clients, may help you sincerely:

(1) How to guarantee the quality of the products?

We have established the international advanced quality management system, every link from raw material to final product we have strict quality test; we resolutely put an end to unqualified products material flowing into the market. At the same time, we will provide necessary follow-up service assurance.

(2) MOQ

For trial order, we accept 10 MT.

(3) Payment term

20% deposit, balance against the BL copy; 100% L/C at sight.

(4) How long can we receive the product after purchase?

We have large quantity in stock, and we could machine it to the size you need, so the delivery time is around 25 days after receiving your deposit or L/C.

- Q:After electrolysis of CuCl2 solution with graphite electrode for a period of time, we can observe that the graphite surface attached to the DC power supply is attached to the red material,And will the color of the solution be deep or shallow?

- During electrolysis, cations move toward the cathode, electrons are reduced at the cathode, anions are moved toward the anode, electrons are lost at the anode and oxidized. And you use both sides of the graphite rod, is inert electrode, so there will be no copper ions added to the solution, copper in the solution of consumption, the color of natural shallow.

- Q:Can graphite be used as an electrode for electrolysis of silver in silver nitrate?

- If it is molten, it can be made out of silverFor solution, only AgNO3+H2O== electrolysis ==Ag+HNO3+O2 is analyzedWhen the HNO3 concentration is enough, it will continue to react with Ag.... So you can't get Ag elements.

- Q:Iron and graphite as electrodes and Nacl as electrolyte solutions. Why do they produce electric current? Graphite and iron react not with solution, can they be connected by wires?

- Graphite here acts only as an electrode, and the real reaction on the graphite is oxygen, the galvanic cell reaction called iron oxygen corrosion

- Q:Is graphite flammable?Why do I bake pencil cores with a fever that doesn't burn?

- In theory, as long as a certain temperature is reached, any substance can be burned, and the diamond is converted to graphite at 2000~3000 DEG C under anaerobic conditions. That is to say, graphite (flake graphite)

- Q:Electrolysis of CuCl2 solutions with graphite electrodes

- CuCl2 refers to a copper chloride ionization ionization ion and chloride ion in aqueous solution, the equivalent of CuCl2 does not exist, but there are only Cu2+ and Cl-, even if there is no electricity, the ionization will happen, because this is the nature of it.

- Q:Why is graphite conductive electrode oxidized?

- The reason for its oxidation is that it is oxidized at atmospheric temperature by reacting with the oxygen in the air

- Q:Carbon graphite electrode and what is the difference?

- The material is composed of carbon carbon, but without graphite, after molding sintering temperature is only more than 1000 degrees, no graphitization.

- Q:What are the losses in graphite electrode?

- In EDM, discharge principle is to remove the workpiece material by using the tool and the workpiece anode spark discharge explosion, spark discharge is bidirectional, not only will the workpiece removal part, forming processing, will cause some loss of electrode. Electrode loss is one of the main causes of machining errors in machining, and is an important technical parameter affecting the accuracy and quality of EDM

- Q:The graphite electrode made by the machining center adopts cooling method, which is water cooled, oil cooled and blow cold. Which is good?

- In addition, the infiltration of water on graphite is not good, can not get the effect of dust removal. Now there are special graphite machine, sealing system. Air-cooled can be used, after all, the best air-cooled.

- Q:Specification for graphite electrodes commonly used in steel works

- General specification for graphite electrode diameter Phi 300 Phi 500mm, Phi Phi 550 - the current usage of 800mm graphite electrodes is also great, the graphite electrode length was between 1600 and 2700mm.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

High Density SHP Grade Graphite Electrode with Nipples

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 1500 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products