PP Biaxial Geogrid 30kn/30kn for Road Reinforcement Project

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 900000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

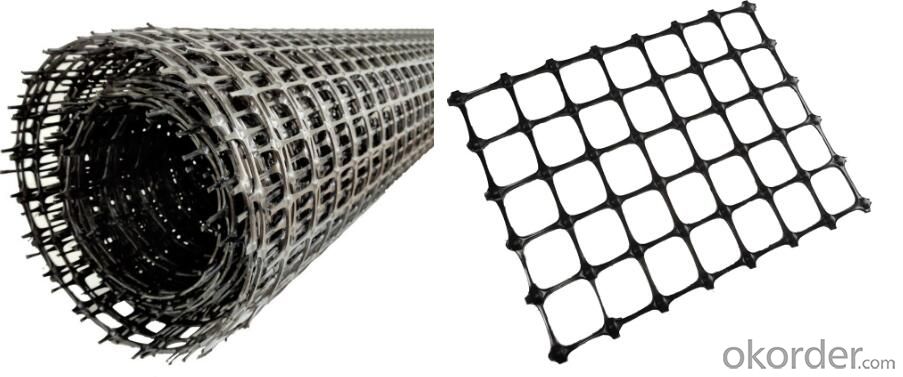

Introduction of PP Biaxial Geogrid:

1.Description of PP Biaxial Geogrid

CMAX PP geogrid is made of polymer and certain additive by extrusion technology.

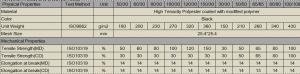

2.Specification of PP Biaxial Geogrid

Tensile Strength: 15-15KN; 20-20KN; 30-30KN; 40-40KN;

Road Size: 3.95x100m; as customer required;

Types: Biaxial;

3. Technical Data Sheet of PP Biaxial Geogrid

Specification | Unit | Test Method | GG1515 | GG2020 | GG2525 | GG3030 | GG4040 |

Polymer | - | PP | |||||

Minimum Carbon Black Content | % | ASTM D 4218 | 2% | ||||

Weight (Tolerance: 10%) | g/m2 | - | 180 | 230 | 270 | 330 | 460 |

Tensile Strength(MD, TD) | KN/m | ASTM D 6637 | 15 | 20 | 25 | 30 | 40 |

Peak Strain (MD, TD) | % | ASTM D 6637 | 13 | 13 | 13 | 13 | 13 |

Load at 2% strain(MD, TD) | KN/m | ASTM D 6637 | 5 | 7 | 9 | 14 | |

Load at 5% strain(MD, TD) | KN/m | ASTM D 6637 | 7 | 14 | 17 | 21 | 28 |

Junction Efficiency | % | GRI GG2 | 95 | ||||

Flexural Rigidity | mg-cm | ASTM D 7748 | 690,000 | 1,090,000 | - | 3,930,000 | 11,480,000 |

Aperture Stability | m-N/deg | COE Method | - | ||||

4.Property of PP Biaxial Geogrid

1). Not easy to produce static after friction. In the coal mine, surface static resistance average is below 1 x 10^9

2). Good flame retardant performance, melt not burning under glam environment, even burning it will extinguish in 10s.

3). Strong anti-corrosion property.

4). High bearing capacity, low elongation.

5.Application of PP Biaxial Geogrid

Coal mine channels, more than 2 layers needed if for false roof use.

FAQ

Q: Can you accept sample order?

A: Yes, we are willing to send small samples for free, while the shipping fee should be afforded by yourself.

Q: What is your delivery time?

A: 1 days for samples, two weeks for mass production.

Q: What is your payment terms?

A: T/T , L/C, Western Union, Money Gram. 30% advance before producing, 70% payment before deliverying.

Q: How can I get my order?How can I know you sent the goods.

A: We will send you the goods by UPS, DHL, Fedex, Oversea Shipment or other forwarder,

all with tracking number or B/L.

Q:How about your quality?

A: Try a small order, you will have your own judgment!

Q: what esle product do you need?

A: pp nonwoven geotextile, pp woven geotextile, geomembrane, polyester geogrid, fiberglass geogrid, geocomposite, etc.

- Q:Can geogrids be used in ground stabilization for pipelines?

- Yes, geogrids can be used in ground stabilization for pipelines. Geogrids are commonly used in pipeline construction to reinforce the soil and prevent lateral movement or settlement. They provide additional support and stability to the ground, ensuring the pipeline remains in place and minimizes the risk of damage or failure.

- Q:What are the factors that affect the long-term oxidation resistance of geogrids?

- The factors that affect the long-term oxidation resistance of geogrids include the type of polymer used in the geogrid manufacturing, the quality of the polymer, the exposure to UV radiation, temperature fluctuations, and the presence of chemicals or pollutants in the surrounding environment.

- Q:What are the advantages of using geogrids in ground improvement for settlement control?

- Geogrids offer several advantages when used in ground improvement for settlement control. Firstly, they provide increased stability to the soil, preventing excessive settlement and erosion. Secondly, geogrids distribute the load more evenly, reducing the stress on the soil and minimizing potential settlement. Additionally, geogrids are highly durable and resistant to degradation, ensuring long-term effectiveness. Finally, using geogrids in ground improvement projects is a cost-effective solution, as they require minimal maintenance and can be easily installed. Overall, geogrids are an efficient and reliable method for controlling settlement and improving the stability of the ground.

- Q:Can geogrids be used in stormwater detention systems?

- Yes, geogrids can be used in stormwater detention systems. Geogrids are commonly used as a reinforcement material in these systems to enhance the stability and strength of the soil. They help to prevent soil erosion, improve drainage, and increase the overall efficiency of stormwater detention systems.

- Q:Can geogrids be used in stabilization of coastal dunes?

- Yes, geogrids can be used in the stabilization of coastal dunes. Geogrids are commonly used for soil reinforcement and erosion control, making them effective in preventing dune erosion and maintaining their stability. By installing geogrids, the dune's natural sand and vegetation can be retained, while preventing sand displacement and erosion caused by wind and waves.

- Q:How do geogrids enhance the performance of geotextile tubes?

- Geogrids enhance the performance of geotextile tubes by providing additional strength, stability, and reinforcement to the structure. They help distribute and transfer the loads more efficiently, improving the overall stability and resistance to deformation of the geotextile tubes.

- Q:The dam is protection of geomembrane or gabion.

- The protective effect is good, and the soil erosion is prevented

- Q:What are the installation guidelines for geogrids?

- The installation guidelines for geogrids typically include steps such as preparing the subgrade, ensuring proper compaction, securely anchoring the geogrid, and properly overlapping and connecting multiple rolls. Additionally, the guidelines may outline specific requirements for site preparation, equipment, and quality control measures to ensure a successful installation of geogrids.

- Q:What is the typical length of a geogrid roll?

- The typical length of a geogrid roll can vary depending on the manufacturer and application, but it is usually around 50 to 100 meters in length.

- Q:What is the effect of creep on geogrid performance?

- Creep can have a significant impact on the performance of geogrids. Over time, the constant stress and strain on the geogrid can cause it to slowly deform and lose its original shape and strength. This can result in reduced load-bearing capacity and overall effectiveness of the geogrid in reinforcing and stabilizing the soil. It is important to consider creep behavior when designing and selecting geogrids for long-term applications to ensure their durability and performance.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

PP Biaxial Geogrid 30kn/30kn for Road Reinforcement Project

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 900000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords