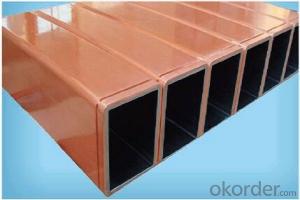

High Density High Purity Copper Alloy Bar

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 kg

- Supply Capability:

- 10000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product: High Density High Purity Copper Alloy Bar

Type Specifications: T2, TU1, TU2, TP2

Produced by low-vacuum copper smelting casting technology with its intellectual property right owned by Feichi Copper & Aluminum; high density and high purity product with low hydrogen and oxygen content, usually processed into copper products of various shapes and widely applied in steelmaking, electric power, shipbuilding, and machinery sectors

Application:

Produced by low-vacuum copper smelting casting technology with its intellectual property right; high density and high purity product with low hydrogen and oxygen content, usually processed into copper products of various shapes and widely applied in steelmaking, electric power, shipbuilding, and machinery sectors

Special Shaped tungsten products

We produce special shaped tungsten products and other OEM products.

Production Equipment

750-1500kg main frequency induction copper melting furnace, 80MN water seal extruder, LG60 high speed two-roll cold pilger mill, straight-line wire-drawing machine, copper tube/pipe straightener, polisher, 84′ copper coil winding machine, straightening-cutting & pancake coiling machine, thermoplastic packaging machine, 1.2T continuous bright annealing furnace.

80MN extruder

Continuous bright annealing furnace

Testing Devices

spectrum analyzer, atomic absorption analyzer, spectrophotometry, analytical balances, metallurgical microscope, eddy current flaw detector, metal tensile testing machine, eddy conductivity instrument.

Hardness tester

Spectrum analyzer

Metallurgical microscope

Metal tensile testing machine

Atomic absorption analyzer

Process

refined copper — smelting & casting — extrusion — rolling — drawing — straightening-cutting/forming of pancake coil — bright annealing — packaging — finished goods.

Standards

GB/T 1527-2006 Drawn tube of copper and copper alloys

GB/T 16866-2006 Dimensions and tolerances of copper and copper alloy seamless tubes

GB/T 4423-2007 Copper and copper-alloy cold-drawn rod and bar

GB/T 5231-2001 Wrought copper and copper alloys chemical composition limits and forms of wrought products

GB/T 5585.1-2005 Copper or aluminium and its alloy bus bars for electrical purposes—Part 1:Copper andcopper alloy bus bars

GB/T 17791-2007 Seamless copper tube for air conditioner and refrigeration equipment

GB/T 19850-2005 The seamless round copper tubes for electrical purposes

GB/T 26024-2010 Seamless copper and copper alloys tube for valves on air-conditioning and refrigeration system

ASTM B280-2008 Standard Specification for Seamless Copper Tube for Air Conditioning and Refrigeration Field Service

EN 12735-1:2001 Copper and copper alloys Seamless,round copper tubes for air-conditioning and refrigeration Part 1:Tubes for piping systems

EN 12735-2:2001 Copper and copper alloy – seamless round copper tube/pipe for air-conditioning and refrigeration system – for equipment

JIS H3300-2009 Seamless copper and copper alloy tube/pipe

- Q:I know that it is not related to the AC unit or the water heater.

- u have a major leak,call a repairman.

- Q:how to sustain copper ore?

- What do you mean by sustain? Copper and all metals are recycled as much as possible. In most cases, it is easier to reclaim metal from scrap metal than it is to dig ore out of the ground and produce metal in the first place.

- Q:Having trouble soldering copper pipe?

- Clean the end of the pipe with 'wet and dry' paper or emery cloth. Clean it by going around the pipe, not longitudinally. (that's important). Wipe the cleaned area with a smearing of flux. Apply heat just before the cleaned area, NOT on it otherwise you will quickly cause oxidation. Your torch should be about 60% of it's max. Too hot and the copper will oxidise, too cool and it won't be hot enough to melt the solder. Ensure that you are using the correct melting point solder for the job. Hold the solder in one hand and apply it to the tube, playing the flame on and off and round the pipe. You need to get the heat to just the point where the solder begins to run. As soon as the solder runs, wipe it round with a mole skin cloth. (I use a leather garden glove, it works a treat, I can wipe it round and clean without getting burned leaving the end just silvered. When you have mastered that then you can move on to joining the pipes together with an end solder socket or, if you prefer, a yorkshire soldered socket. If the copper pipe changes color to a light reddish brown then you have applied too much heat. Likewise if the solder runs off like water. You need to get the heat to where the solder is between running off and being plastic.

- Q:Hebei air conditioning copper pipe quota already included pipe fittings? I know the branch pipe needs to be calculated separately, but the elbow is not clear enough! Who knows, tell me!

- Of course, special fittings to extra computation, like the elbow, three, four, B word and so on are all special bending pipe, they design a bit more complicated, and each pipe is not the same price, much higher than the same material price straight, hope to help you

- Q:There is a 1/2 copper pipe coming up from under the foundation of my house that just sticks out of the ground about 12 or so, and what I believe is 1 1/4 PVC pipe coming from the water heater (maybe a drain?) and doing down the same hole. The hole is plugged up with firestop, but I‘m trying to make the closet the water heater is in a little easier on the eyes, new paint, etc. Is this copper pipe still in some kind of service? or could I cut it off and fill it, too, with firestop before painting the closet floor (bare concrete) with some kind of concrete/garage paint?

- I would guess that the 1/2 inch copper pipe is either an old supply line or a line that used to run to an outside faucet. In either case, if the end of it is not plugged or capped off, cutting it off shouldn't hurt anything. The other pipe should be a 3/4 inch pipe from the pressure/ temperature relief valve on the tank and should be running to a drain or an area where flooding will not harm anything, such as an open crawl space. If the end of that pipe is just open to the floor of a living area, it could cause a major flooding situation if the valve ever pops off. You really should have it routed to a place where water won't hurt anything.

- Q:i want to know which type of copper is having less plastic deformation when subjected to load. it should easily regain its shape to a great extent when the load acted on it is removed

- BERYLLIUM COPPER Beryllium copper alloys are widely used in military aerospace applications because of the unique desirable properties imported by the beryllium alloying of copper. Because of the toxicity of beryllium and the health hazard it produces, beryllium usages is becoming quite restrictive and may be completely eliminated. In spite of previous development efforts no copper alloy has been developed which can match the properties of copper-beryllium (CuBe) alloys. This program will investigate three approaches which have not heretofore been investigated and which have a very high probability to produce a material which has properties equal or superior to CuBe and can serve as an alternative material. The three material compositions will be produced and fully characterized for high-load, stress and wear applications to permit selection of one composition for further optimization in the option periods and Phase II. The best Phase I material will be delivered to the Navy.

- Q:Copper slag uses.

- In some remote areas where no suitable rock for road aggregate is available, copper slag has been crushed and used in bitumen and in railway ballast. In old mines where the mineral recovery was poor and the slag is rich in copper, attempts have been made to reprocess the slag to extract the copper and any other useful elements.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

High Density High Purity Copper Alloy Bar

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 kg

- Supply Capability:

- 10000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords