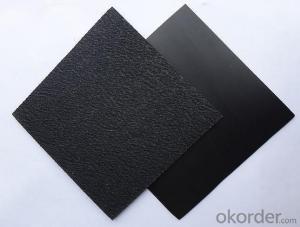

High Density Best Quality Polyethylene Geomembrane as Waterproof Facing of Earth and Rockfill Dams

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Production

HDPE Impermeable Geomembrane offers a cost-effective way to eliminate reservoir and dam water loss.

The installation of a UV-stable membrane lining system not only resolves unwanted water leakage (from cracks and/or porous soil),

HDPE Impermeable Geomembrane will also prevent chemicals from leeching into or out of the dam, pond or reservoir.

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

geotextile fabric

permeability,filtration,easy for construction

ISO and CE certificate

Good quality and competitive price

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

After-sales service

1.In order to provide customers with comprehensive technical support,we will provide technical and other related information upon request in a timely manner.

2.In required,we will appoint specialized technicians to the construction site to give technical trainings to construction people,and offer technical guidance throughout the whole construction process.

3.For damage due to shipment and delivery,after we receive the complaint,we will check the issure through provided pictures and videos.If our responsibility is confirmed,we wil offer free replacement.

4.When the construction is completed,as your request,our technical staff may participate in the final acceptance.

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q:Are geotextiles commonly used in canal lining applications?

- Yes, geotextiles are commonly used in canal lining applications. They provide effective erosion control and filtration, preventing the loss of soil particles and maintaining the stability of canal embankments. Additionally, geotextiles can enhance drainage and reduce seepage, improving the overall performance and longevity of canal lining systems.

- Q:How do geotextiles help with sediment filtration in stormwater ponds?

- Geotextiles help with sediment filtration in stormwater ponds by acting as a barrier to prevent sediment from entering the water. They are placed at the bottom of the pond or along the sides to trap sediment particles while allowing water to flow through. This helps in reducing the amount of sediment that settles in the pond, ensuring cleaner water and improving the overall efficiency of the stormwater management system.

- Q:Can geotextiles be used in landfill applications?

- Yes, geotextiles can be used in landfill applications. They are commonly used as part of the liner system in landfills to separate and stabilize different layers of soil and prevent the migration of contaminants. Geotextiles help enhance the overall performance and environmental protection of landfills by promoting proper drainage and reducing the potential for erosion.

- Q:How do geotextiles improve drainage systems?

- Geotextiles improve drainage systems by acting as a filter and separator, preventing the clogging of soil particles and allowing water to flow freely through them. This helps in preventing soil erosion, maintaining the stability of the soil, and enhancing the overall effectiveness of the drainage system.

- Q:Can geotextiles be used in flood protection projects?

- Yes, geotextiles can be used in flood protection projects. Geotextiles are often used as a component in flood control measures due to their ability to effectively filter and drain water while preventing soil erosion. They can be employed in various applications such as erosion control, slope stabilization, and shoreline protection, helping to mitigate the impact of floods and minimize damage to infrastructure and property.

- Q:What is the length of the lap in the geotextile in the tunnel?

- General 20cm can be, I produce geotextile materials

- Q:Can geotextiles be used in land reclamation projects?

- Yes, geotextiles can be used in land reclamation projects. Geotextiles are often employed to stabilize soil and prevent erosion during the reclamation process. They provide a barrier that separates different soil layers, allowing water to drain while preventing the loss of fine particles. Additionally, geotextiles can reinforce weak soils, increase their load-bearing capacity, and promote vegetation growth, making them a valuable tool in land reclamation projects.

- Q:Are geotextiles suitable for use in contaminated soil remediation projects?

- Yes, geotextiles are suitable for use in contaminated soil remediation projects. Geotextiles can act as a barrier to prevent the spread of contaminants, while also allowing water and air to pass through. They can be used to separate clean and contaminated soils, provide stability to slopes, and enhance the effectiveness of other remediation techniques such as phytoremediation or soil vapor extraction. Additionally, geotextiles are durable and cost-effective, making them a practical choice for soil remediation projects.

- Q:How do geotextiles affect groundwater flow?

- Geotextiles can have both positive and negative effects on groundwater flow. When properly installed, they can act as a barrier, reducing the infiltration of surface water into the groundwater system. This can help in controlling erosion and preventing contamination of the groundwater. However, if geotextiles are not installed correctly or become clogged with sediment over time, they may impede the natural flow of groundwater, causing water to accumulate and potentially leading to localized flooding or the alteration of natural recharge patterns. Therefore, the impact of geotextiles on groundwater flow depends on their design, installation, and maintenance.

- Q:What are the different types of geotextiles?

- There are several different types of geotextiles, including woven geotextiles, non-woven geotextiles, and knitted geotextiles. Woven geotextiles are made by weaving synthetic fibers together, creating a strong and durable material. Non-woven geotextiles are made by bonding or felting synthetic fibers together, providing filtration and drainage capabilities. Knitted geotextiles are produced by interlocking synthetic yarns, offering high tensile strength and flexibility. Each type of geotextile serves specific purposes in various applications, such as erosion control, soil stabilization, and drainage systems.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

High Density Best Quality Polyethylene Geomembrane as Waterproof Facing of Earth and Rockfill Dams

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords