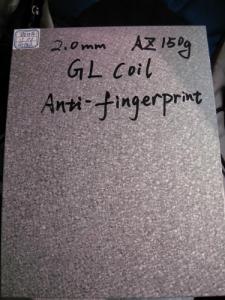

High Coating Galvalume Steel Coil

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Hot Dipped Galvalume Sheet as per ASTM A 792 CS (Type A), AZ 150, Anti Fingerprint,

~ Regular Spangle, with side one PVC Film

~ AL 55%, ZN 42%, Si > 1.5%

SIZE (MM) (TCT) MOQ (MTS)

1.0 x 1250 x C 100

1.5 x 1250 x C 100

2.0 x 1250 x C 100

COIL ID: 508MM

COIL WEIGHT: 4-6MTS

VALIDITY: 3 WORKING DAYS

PAYMENT: T/T WITH 20% DOWNPAYMENT AND BALANCE AGAINST INVOICE & PACKING LIST

SHIPMENT: 75 DAYS AFTER T/T 20% DOWNPAYMENT

- Q:Can steel coils be coated with thermally conductive materials?

- Yes, steel coils can be coated with thermally conductive materials. These materials are often applied as a thin layer or coating onto the surface of the steel coils to enhance their thermal conductivity. This coating helps in the efficient transfer of heat through the coils, making them suitable for various applications that require effective heat dissipation or thermal management.

- Q:At what temperature does steel start to warp or soften.

- It depends upon the composition of steel. Carbon steel, which does not have many alloying elements, softens around 1200C while with alloying elements, this transition temperature either drops or raises depending upon what is added. Higher carbon makes this temperature drop. This is a very important question for forging since if a lower temperature is used, forging won't be easy and at higher than softening temperature, it is not easy to handle. The temperature at which steel begins to soften is, in general, much above what the metallurgists call AC1 or AC3 temperature.

- Q:How are steel coils used in the production of shelving units?

- Steel coils are used in the production of shelving units by being cut and formed into various components, such as brackets and supports. These components are then assembled and welded together to create the frame and structure of the shelving unit. The steel coils provide strength and durability to the shelving units, ensuring they can withstand heavy loads and provide long-lasting storage solutions.

- Q:what is the differance between ceramic and stainless steel headers and 4-2-1 and 4-1 and which are better for racing and should i get ceramic or stainless steel headers???? for a 98 civic

- 1) okorder ... The top two are of 4-1 design. Good luck, have fun.

- Q:What are the common coil thicknesses available for steel coils?

- The common coil thicknesses available for steel coils can vary depending on the specific application and industry requirements. However, some of the most common coil thicknesses for steel coils range from 0.5mm to 3mm. These thicknesses are commonly used in various manufacturing processes, including automotive, construction, and appliance industries. For lightweight applications or where flexibility is required, thinner steel coils with thicknesses ranging from 0.5mm to 1.5mm are often used. These thinner coils are suitable for applications such as automotive body panels, roofing, and general sheet metal fabrication. On the other hand, for applications that require higher strength and durability, thicker steel coils with thicknesses ranging from 1.5mm to 3mm are commonly used. These thicker coils are often utilized in heavy-duty construction, structural components, and industrial equipment manufacturing. It is important to note that these are just general ranges, and specific coil thicknesses can vary depending on the specific requirements of a particular project or customer preference. Steel coil thicknesses can be customized to meet specific needs, allowing for greater flexibility in various industries.

- Q:What are the main characteristics of galvanized steel coils?

- The main characteristics of galvanized steel coils include their high corrosion resistance, durability, and ability to withstand extreme weather conditions. They are also known for their excellent formability, making them suitable for various applications in construction, automotive, and manufacturing industries. Additionally, galvanized steel coils have a smooth and shiny appearance due to the zinc coating, which provides aesthetic appeal along with enhanced protection against rust and other damages.

- Q:Also, what is the top best slow cooker that is 100% stainless steel? Thank you!

- My SS pans are Prestige.

- Q:How are steel coils protected from extreme weather conditions?

- Steel coils are typically protected from extreme weather conditions using various methods such as covering them with waterproof wraps, storing them in climate-controlled warehouses, or applying anti-corrosion coatings. These measures ensure that the coils are shielded from moisture, temperature fluctuations, and other environmental factors that could potentially damage or degrade the steel.

- Q:Can steel coils be coated with polymer?

- Yes, steel coils can be coated with polymer.

- Q:I'm putting a bathroom in my basement. I'm an Ironworker btw. I wanted to go with steel studs due to the fact that they are light, and I won't have a big mess. I live in the Chicago area and they should be easy to find. Here is my question. Are they not being used anymore? I ordered 100 studs from Lowe's but they didn't have track. The delivery guy was a retired Carpenter and he told me that I got all the studs they had, they no longer stock steel studs, and they don't have track. Am I missing something? Menards didn't have track either.

- Steel studs are mainly for commercial applications on non bearing walls. 100 studs, must be one big assed bathroom. Do yourself a favor and install a pressure treated bottom plate, even if you use steel studs.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

High Coating Galvalume Steel Coil

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords