high carbon spring steel wire used for flexible duct of cnbm

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Place of Origin: | China (Mainland) | Type: | Other | Brand Name: | cnbm |

| Material: | Other | Application: | Other | Tensile Strength: | ≥50Mpa |

| product: | steel wire | Rated Voltage: | as customer required |

Packaging & Delivery

| Packaging Detail: | Packaging & Delivery Packaging Detail: 1coil/polybag polybags/carton cartons/pallet Or nude packing as the custom requirement Delivery Detail: According to customers'requirement |

| Delivery Detail: | within 10 days after received your payment |

Specifications

high carbon spring steel wire

1.Material for flexible ducts

2.We are manufacturer

3.We supply spring steel wire,aluminized

Specifications

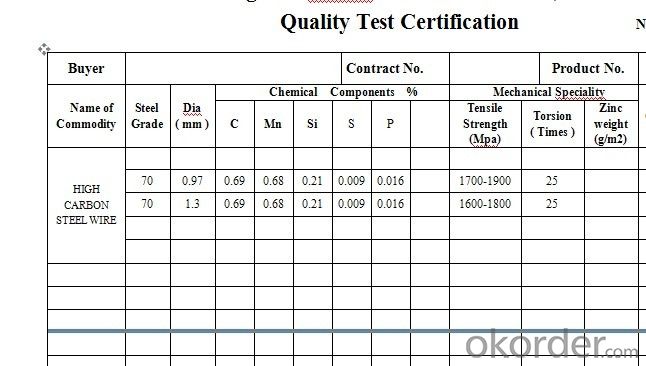

1.Material: 60#, 70#, 75#, 72A, 72B, 82B, 65Mn

2.Diameter range: 0.15-12. 0mm

3.Standard: GB4357-89, DIN17223

4.Shipment: Prompt

5.weight: As the buyer's requests

6.We supply spring steel wire,aluminized PET,aluminium PET foil,PVC,ect

Wire diameter | 0.15-12mm |

T/S | 1500-2900N/mm2 |

Packing

- Q:im hooking up a air/fuel tomorrow and i need to know what color the wire for the sensor signal is on my rt... i have 4 wires and heres the colors and were they are from. t/w or o/t from c124 b/lbl from c14 and c315 b gound and o/dg from fuse a... need answer thanks

- It should be the BLK/ LB wire (although my wiring schematic shows that wire BLK/ GREEN), It will be the only circuit that have a varying voltage between 0-1 volt. Probe the wires with a DVOM and determine which wire has the signal, one wire will supply B+ for the heater, one is heater ground, one is reference supply voltage and one is signal return The signal return is the circuit you need to tap.

- Q:Two steel wires are stretched with the same tension. The first wire has a diameter of 6.00E-4 m and the second wire has a diameter of 8.90E-4 m. If the speed of waves traveling along the first wire is 53.2 m/s, what is the speed of waves traveling along the second wire?

- Wave velocity v = √(T/μ) Same tension in both wires: T1 = T2 μ is the linear mass density v1 = 53.2 m/s v2 = ? = v1/v2 = √(T1/μ1) / √(T2/μ2) = √(T1μ2 / T2μ1) = √(T1/T2 * μ2/μ1) = √(μ2/μ1) Linear mass density is mass/length, mass is density*volume: m/L = ρV/L = ρAL/L = ρA = ρπr^2 Both wires are steel so their density is the same. == v1/v2 = √(μ2/μ1) = √(ρπr2^2 / ρπr1^2) = √(r2^2 / r1^2) = r2/r1 == v2 = v1r1/r2 = (53.2*3.00×10^-4) / 4.45×10^-4 = 35.9 m/s ---- Speed of waves along the second wire is 35.9 m/s

- Q:Why is it that some wires get hot,having electricity flow throught them,while others don't?And why is it that when there is a lot of resistance in a wire, that it doesn't get hot?Why does the length of a wire has an effect on the temperature of that wire, and how exactly?

- Well it depends. If you varry the current the temperature of the wire will also vary. You have to take into account the actual diameter of the wire, the wider the wire, and constant current, the cooler the wire will be when you run electricity through it. If you have a wire with HIGH resistance it will get HOTTER, thats how light bulbs work.

- Q:How is the line differ from a neutral and ground wires in a three prong plug?

- In your standard outlet, (NEMA 1-15 or 5-20 receptalce/plug): The 'Line' is the smaller slot/prog The 'Neutral' is the large slot/prong The ground is the 'pin'/prong.

- Q:i need to know how much wire size i have to put for 380 volts supply

- Wire size is a function of current, not voltage. So, how much current is your load going to draw.

- Q:how to wire the alternator for a 77 mustang

- Ever thought about just putting a one wire alternator in there and doing away with the external voltage regulator. Its a nice upgrade.

- Q:The wire from the pinball machine only has two wires. How do I rewire the machine with a grounded wire and plug?

- Just go to your home cente or electric supply house, and get as long as you need of 16/3 SJO or SJTW cord and a grounded plug, and replace the cord there.

- Q:I have a wire coming from the car battery positive terminal. It is 12v DC. I want to split this wire to two other wires. I cannot connect another wire to the positive terminal. Will splitting this wire cause the voltage to drop to 6v each wire? or will they pull a constant 12v each?

- They will each have 12 volts. But the split wire may be too thin for the current. Instead, connect the wire to your first load, then a wire from there to the second load.

- Q:like can u use home power wire that is 4 gauge rather then getting the car power wire

- Wire is wire but stranded wire is better than solid which is generally used in home wiring. The gauge of the wire is what is most important. The gauge of wire is determined by the amperage of the equipment. 16AWG - 10A 14AWG - 15A 12AWG - 20A 10AWG - 30A 8AWG - 55A 6AWG - 75A 4AWG - 95A 2AWG - 130A 0AWG - 170A

- Q:I plugged in my new Pioneer DEH-P6500it worked for a little bit until i moved it around a littlethe speakers started to go out but the subs still sounded finei messed around with it and found the wire responsible for it allits a red wireit says AAC or somethingif i messed with the copper twist the speakers would come in and outi stripped the wire a little and put it back together but now the head unit wont even turn onand im also left with like 2 inches of red wireis my only option to get a new pioneer wire harness?what is the problem?the red wire i think supplies the power to the whole head unit because when its not connected, the whole thing turns onbut only the speakers go on and off when i messed with itbut it wont turn on anymore

- You may have blown a fuse. Check the fuse on the back of the radio and your car fuse for the radio.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

high carbon spring steel wire used for flexible duct of cnbm

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products