HIGH CARBON FERRO CHROME FECR ALLOYS MANUFACTURER SUPPLY CIQ APPROVAL

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Ferro Chrome

Chrome is always used to improve the antioxidation and corrosion resistance of steel to make the surface of steel after it is oxidized to form strong adhension oxide film. Then it stops being oxidized or decelerates being oxidized.Micro-Carbon ferro chorme is applied to making stainless, acid-resistant steel and heat resistant steel.

Chrome is mainly used to improve the antioxidation and corrosion resistance of steel to make the surface of steel after it is oxidized to form strong adhension oxide film. Then it stops being oxidized or decelerates being oxidized. Micro-carbon ferro chrome is applied to making stainless steel, acid-resistant steel and heat resistant steel.

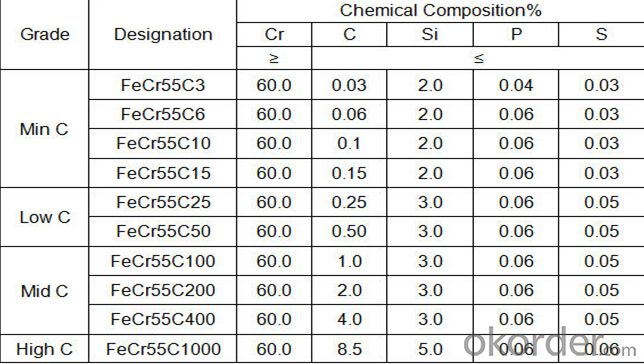

Specifications

High Carbon Ferro Chrome

1. Original manufacturer

2. The stability of the shipments

3. Free samples

4. Relatively lower cost

Products information

1. It can be used to produce FerroChrome and Chrome metal in metallurgy industrial.

2. As a kind of steel addition,it is used to produce various special steels with high strength,corrosion resistance,anti-friction,thermostability and anti-oxydic.such as stainless steel,acid-resistant steel,heat-resistant steel,spring steel,tool steel and so on.

3. Chromite is used to produce Chrome brick,,Chrome-magnesium brick and other special refractories in fireproofing.

Specifications

1. Ferro chrome

1).Type;HC MC LC

2).Brand:FeCr67C6.0,FeCr55C600,etc

3).strict quality control

4).Factory price

2. High Carbon Ferro Chrome

Ferro Chrome

FeCr

1).ChemicalCompositions:Fe,Cr,C,Si,P,S

2).Type:High,Medium,low,MicroCarbon

3).FeCr67C6.0,FeCr55C600,etc

4).Improve antioxidation.

Packaging & Delivery

Packaging Detail: | 1MT/BAG |

Delivery Detail: | 15-30days |

- Q:One can write on the hard alloy on the pencil, what's the name ah, who knows.

- What pen is this?Chasing the answer230 yuan each. You can contact me any time you like.

- Q:Carbide drills and cobalt high speed steel bit, which is good? What's the difference between these two materials?

- The two materials are not good or bad, the key is to look at the application!!Carbide drill, high hardness, wear resistance, high efficiency, toughness slightly worse, therefore, the rigidity of the machine tool and spindle runout and speed are required!Cobalt high speed steel including ordinary high-speed steel, good toughness, edge processing can be very sharp, more suitable for processing some sticky materials, of course, low strength materials will be nothing difficult, but its high temperature resistance, wear resistance is relatively poor, the drilling speed is not high!!Therefore, the choice of drill or according to your working conditions to choose,

- Q:What is a hard alloy mixture?

- The cemented carbide mixture refers to a WC+Co mixture to be suppressed, and contains a small amount of additives (possibly paraffin, rubber, etc.) that can improve the compressive properties. There is also a saying called RTP (Ready To Press).

- Q:Chengdu which has carbide scrap acquisition point?

- What alloy do you have? A lot of home cash recycling, big price worries, good faith cooperation! This site in Jinniu District this way

- Q:What materials are hard alloys used to process?

- YG hard alloy, impact resistance, high temperature resistant, processing pig iron.

- Q:What are the well-known brands of cemented carbide materials at home and abroad?

- A lot of foreign ah, Sweden Sandvik, German - Luxemburg, American Kenna, Israel - Domestic - hard line iscar; diamond, Zigong the Great Wall, Xiamen gol-egret etc.

- Q:Which is better, cemented carbide, YG8 and YG20?

- YG8 is generally used to do small size drawing die, the wear force is not large, such as the impact is not great, requiring wear-resistant, with YG8;YG20 is generally used as cold stamping die, cold heading die and so on

- Q:How much does carbide WC contain?

- For example, YT15, which represents average TiC=15%, is tungsten carbide cobalt carbide with the remainder of tungsten carbide and cobalt contentTungsten, titanium, tantalum (niobium) carbidesIs the main component of tungsten carbide, titanium carbide, tantalum carbide (or niobium carbide) and cobalt. The hard alloy and hard alloy general or universal hard alloy.

- Q:YW1 what do you mean by "YW" in carbide cutter head?

- Y represents the metallurgical (Yejin) Department standard. W stands for universal (Wanneng) alloy

- Q:There are three kinds of cemented carbides, of which tungsten, cobalt and titanium are brittle cemented carbides?

- Tungsten titanium cobalt carbide a tungsten titanium cobalt carbide consisting of WC%26mdash, TiC, WC and bonded cobalt metal or a multiphase hard alloy consisting of only WC%26mdash, TiC solid solution and cobalt. Cobalt content of alloy 4% ~ 10%, containing TiC5% ~ 30%, margin of WC, mainly used for cutting steel.Hard alloy with high hardness, strength and toughness, good wear resistance, heat resistance, corrosion resistance and a series of excellent performance, especially high hardness and wear resistance of it, even at a temperature of 500 DEG C also remained unchanged, at 1000 degrees C still have high hardness. There is no such term as brittle cemented carbide.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

HIGH CARBON FERRO CHROME FECR ALLOYS MANUFACTURER SUPPLY CIQ APPROVAL

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords