High Carbon Ferro Chrome by Leading Supplie CNBM

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

High Carbon Ferro Chrome by Leading Supplie CNBM

Pictures

Ferro Chrome

Chrome is always used to improve the antioxidation and corrosion resistance of steel to make the surface of steel after it is oxidized to form strong adhension oxide film. Then it stops being oxidized or decelerates being oxidized.Micro-Carbon ferro chorme is applied to making stainless, acid-resistant steel and heat resistant steel.

Specifications

High Carbon Ferro Chrome

1. Original manufacturer

2. The stability of the shipments

3. Free samples

4. Relatively lower cost

Products information

1. It can be used to produce FerroChrome and Chrome metal in metallurgy industrial.

2. As a kind of steel addition,it is used to produce various special steels with high strength,corrosion resistance,anti-friction,thermostability and anti-oxydic.such as stainless steel,acid-resistant steel,heat-resistant steel,spring steel,tool steel and so on.

3. Chromite is used to produce Chrome brick,,Chrome-magnesium brick and other special refractories in fireproofing.

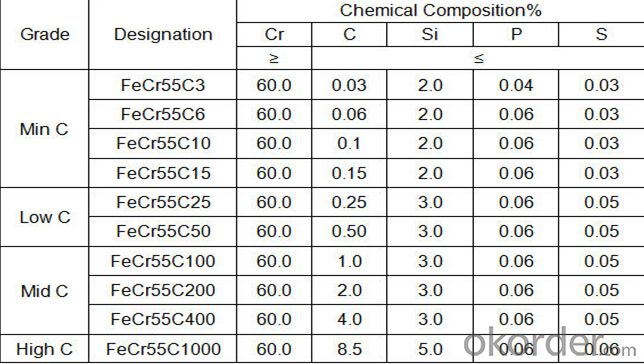

Specifications

1. Ferro chrome

1).Type;HC MC LC

2).Brand:FeCr67C6.0,FeCr55C600,etc

3).strict quality control

4).Factory price

2. High Carbon Ferro Chrome

Ferro Chrome

FeCr

1).ChemicalCompositions:Fe,Cr,C,Si,P,S

2).Type:High,Medium,low,MicroCarbon

3).FeCr67C6.0,FeCr55C600,etc

4).Improve antioxidation.

Packaging & Delivery

Packaging Detail: | 1MT/BAG |

Delivery Detail: | 15-30days |

- Q:Method for assembling hard alloy cold heading die

- Are you the assembly of mould and punch, or the setting of hard alloy die core and steel sleeve when making cold heading die?If the mold and punch assembly, the use of gap assembly, the accuracy depends on the accuracy of your equipment,

- Q:HSS clip can clamp the hard alloy saw it

- The cutter head is mounted on the cutter body and the grinding cutter is called an internal grinding type; the cutter head is individually worn on the fixture and is called external grinding type.Indexable(indexable tools): this kind of structure has been widely used in face milling cutters, end mills and three edged cutters.Product classificationTooth milling cutterA narrow blade is sharpened on the flank to form the back angle, and the cutting angle is reasonable, and the service life is higher. Sharp cutter tooth back straight, curve and line 3 forms.

- Q:Which is better, cemented carbide, YG8 and YG20?

- YG8 contains about 8% cobalt, the hardness is higher than YG20, and the strength is lower than YG20,

- Q:I would like to use carbide cutting tools, car work, ordinary A3 steel or 45 steel, lathe speed to play more appropriate, the workpiece surface quality is better?

- The hungry! For the 450--700 rpm, the most appropriate, because once you and I work almost, I use the 6140 machine, crude car to 450 rpm to 700 RPM fine car is good. If the surface quality is good, the blank is not much, you can use 450 turn into a knife, but the knife grinding......

- Q:The existing 60*60 standard cast iron plate, above 3 hard alloy welding specifications, probably in the 30*30, in which the appropriate welding method, know the friends willing to enlighten ah, thanks in advance.Some friends have said the binder is a copper brazing, the basic can be settled. As far as I know, many methods such as welding, high frequency welding, oxygen welding, I want to find a kind of welding method. The key is to understand the trouble with us, surface and surface welding

- Then an old welder re - welded it once, and it worked out just now. Probably the main point is water welding, the flame can not blow the time is too long, alloy hair red, you have to immediately with the matrix together, right, not only faster, more important still prevail. Because it's not good to come second times if you're not allowed

- Q:Carbide yk20? What do you mean?

- Cemented carbides YK20, Y represent alloy categories - tungsten cobalt, K20 represents cobalt contentDensity g/cm3:14.30-14.60;The hardness of HRA is more than or equal to 86.5;The shear strength is greater than or equal to N/mm2:2350,Performance and usage: with high toughness and wear resistance, suitable for embedding percussive rotary drilling bit, drilling in hard and tight hard rock.

- Q:The difference between cemented carbide YG 15 and yg12

- K30 YG8N YG8 14.5-14.9 160089.5 is suitable for cast iron, nonferrous metals and their alloys and non-metallic materials processing, not smooth, rough and discontinuous cutting section of rough planing, rough milling, drilling, reaming hole and deep hole. K30 YG8 YG10X 14.3-14.7 220089.5 is suitable for the production of small diameter micro drill, milling cutter, rotary file etc.. K35 YG10X YS2T 14.4-14.6 220091.5 is an ultrafine particle alloy, suitable for low speed rough turning, milling of heat-resistant alloy and titanium alloy, as cutting knives and taps, saw blades, milling cutters are preferred. K30 YS2T YL10.1 14.91900 91.5 has better wear resistance and bending strength, mainly used for the production of extruded bars, suitable for general drills, cutting tools and other wear-resistant parts. K15-K25 YL10.1 14.52200 YL10.2 91.5 has good abrasion resistance and bending strength, mainly used in the production of extruded rods, made of small diameter micro drill tool, watch the whole processing, and other cutting tools and wear parts reamer. K25-K35, YL10.2, YG15, 13.9-14.2 210087 are suitable for high tensile steel bars and steel tubes under high compression, for upsetting, piercing and stamping tools under larger stresses. YG15 YG20 13.4-13.7 250085 is suitable for production of stamping die, stamping parts, such as watch spring plates of musical instruments; die punching battery shell, toothpaste tubes; stamping die small size steel balls, screws, nuts etc; twist drill bits.

- Q:What is the specific gravity of cemented carbide?

- Similar to mercury. Tungsten cobalt carbide 14.4~15.3 density, tungsten, cobalt, titanium carbide 9.7~13.2 density, can float in the mercury is a steel knife, sink into the mercury is a cast iron knife

- Q:There are three kinds of cemented carbides, of which tungsten, cobalt and titanium are brittle cemented carbides?

- Cemented carbides are classified into tungsten, cobalt, tungsten, titanium, tungsten, titanium, tantalum and cobalt. Tungsten cobalt carbide knife with: YG6, YG8, YG8N and so on, such carbide cutting tools for processing non-ferrous metals, stainless steel, cast iron and other materials;Tungsten carbide hard alloy knife has: YT5, YT15, etc., this kind of carbide cutting tools for processing steel and other tough materials;Tungsten, titanium, tantalum, cobalt carbide knife with: YW1, YW2, YS25, WS30, etc., this kind of carbide cutting tools for processing heat-resistant steel, high manganese steel, stainless steel and other difficult materials.

- Q:The difference between HSS and carbide knives

- High speed steel which is mainly used in the rapid operation of the machine, its good fatigue performance, high temperature performance is better, but the hardness is generally hard alloy steel mainly refers to alloy steel with high hardness, high hardness of the steel is mainly emphasized in a certain range, but may be brittle or will be relatively large, high performance high temperature, poor.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

High Carbon Ferro Chrome by Leading Supplie CNBM

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products