High Anti-Corrosion Color Coated Steel Coil

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Thickness: 0.3-0.8mm

2. Width: 914-1250mm

3. Inner Diameter: 508mm

4. Weight of Steel Coil: 3-15MT

5. Available Dipped Layer: 50-150g/m2

6. Surface Texture: Normal Coated

7. Type of coating structure: 2/1 Coat the top surface of the steel sheet twice, coat the bottom surface once, and bake the sheet twice.

8. Front side paint thickness: 15-25μm (bottome paint + top paint)

9. Back side paint thickness: 5-10μm

Mechanical Properties

1. Mechanical properties of base metals

Grade | Tensile Test | ||

Yield Strength MPa | Tensile Strength MPa | Elongation A80mm % ≥ | |

DC51D+AZ | 280-325 | 320-500 | 22 |

DC52D+AZ | 240-300 | 270-420 | 26 |

DC53D+AZ | 140-260 | 270-380 | 30 |

2. Common performance of front coating

(1). Thickness: ≥20μm

(2). Pencil Hardness: 2H

(3). 60° specular glossiness of coating: >60

(4). 180°bend: ≤3T

(5). Impact: ≥9J

(6). Salt Fog Resistant: ≥500h

(7). Color difference: <3ΔE

- Q:What are the common methods of painting or coating steel coils?

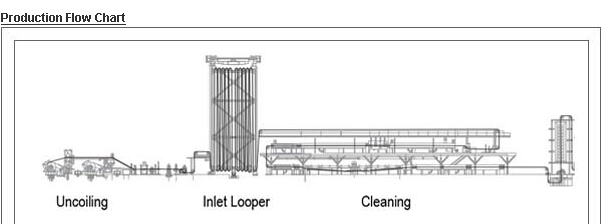

- One common method of painting or coating steel coils is through the process of coil coating. In coil coating, the steel coils are first cleaned and pre-treated to remove any contaminants and improve adhesion. Then, a primer or a base coat is applied to the coils to provide a foundation for the final coating. This primer helps in protecting the steel from corrosion and improves the overall durability of the coating. After the primer is applied, the steel coils pass through a series of rollers where the topcoat is applied. The topcoat can be a variety of materials such as polyester, polyurethane, or fluoropolymer, depending on the desired properties of the final coating. These topcoats provide the desired color, gloss, and protection against weathering, chemical exposure, and UV radiation. Another common method of painting or coating steel coils is through the process of electrostatic spraying. In this method, a paint or coating material is atomized into fine droplets and then charged with an electrical charge. The steel coils, which are grounded, attract the charged droplets, resulting in an even and controlled application of the paint or coating material. Powder coating is yet another method used for painting or coating steel coils. In this process, a dry powder is electrostatically charged and sprayed onto the steel coils. The charged powder adheres to the surface of the steel due to electrostatic attraction. The coated steel coils are then heated, causing the powder to melt and form a continuous film, providing a durable and resistant coating. Overall, these methods of painting or coating steel coils offer a wide range of options in terms of color, finish, and performance characteristics. The choice of method depends on factors such as the desired appearance, level of protection needed, and the specific requirements of the intended application.

- Q:steel bollard poles?

- There those short yellow post's the are too short to see when you back into them.

- Q:Does a magnet stick to galvinied steel?

- I will assume your magnet is a relatively strong one. Virtually all galvanized steel sheet is magnetic. Both galvanized iron and steel are magnetic

- Q:How are steel coils packaged for shipment?

- Steel coils are typically packaged for shipment by being tightly wound and secured with steel bands or straps. They are often placed on wooden skids or pallets to provide stability and protection during transportation. Additionally, protective covers or sheets may be used to shield the coils from moisture and other potential damages.

- Q:I felt that my nylon strings don't sound as good as steel ones. Is it okay that I replace them with steel ones, even if my guitar is classical? Thanks.

- No, you will damage the guitar,it was not create to stand the force on the neck that steel strings will put on it.

- Q:What are the factors that affect the price of steel coils?

- There are several factors that influence the price of steel coils. Firstly, the cost of raw materials such as iron ore and coal, which are essential for steel production, can significantly impact the price. Additionally, the demand and supply dynamics of steel in the market play a crucial role. Factors like economic growth, construction activity, and infrastructure development can drive up the demand for steel, leading to price increases. On the other hand, if there is excess supply or reduced demand, prices may decrease. Moreover, fluctuations in energy costs, transportation expenses, and currency exchange rates can also affect the final price of steel coils.

- Q:I have the game of the year edition for fallout 3 but there's no mission or quest saying it's called broken steel so what is it actually called and where is it? Please describe the quest in case I mightve already done it without even knowing.

- If I can remember right (SPOILER) you have to beat the game and instead of dying you just pass out and wake up with the brother hood of steel.

- Q:I need to know how you rate the hardness of steel any ideas?

- There's an instrument called a hardness tester. It has a stylus which is pressed into the surface of a sample of steel with a calibrated amount of force. The distance it penetrates tells you how hard the steel is. (This is sometimes called 'indentation hardness'). The most common scale is the Rockwell Scale. Actually it gets a little complicated because there are several scales, one for tungsten carbide (the hardest man-made material), one for aluminum and brass and soft steels, and one for hardened steels. Another scale for indentation hardness is the Brinell scale. It's a little less complicated, with one scale to measure the hardness of wood, plastic, etc. as well as steel.

- Q:What are the dimensions of a steel coil?

- The dimensions of a steel coil can vary depending on several factors such as the intended use, manufacturer specifications, and industry standards. However, common dimensions for steel coils typically include variations in width, thickness, and weight.

- Q:What are the common sizes of steel coils?

- The common sizes of steel coils vary depending on the specific application and industry. However, some standard sizes for steel coils include widths ranging from 0.5 inches to 72 inches, and thicknesses ranging from 0.010 inches to 0.250 inches. These sizes can be customized to meet the specific requirements of different industries such as automotive, construction, or manufacturing.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

High Anti-Corrosion Color Coated Steel Coil

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords