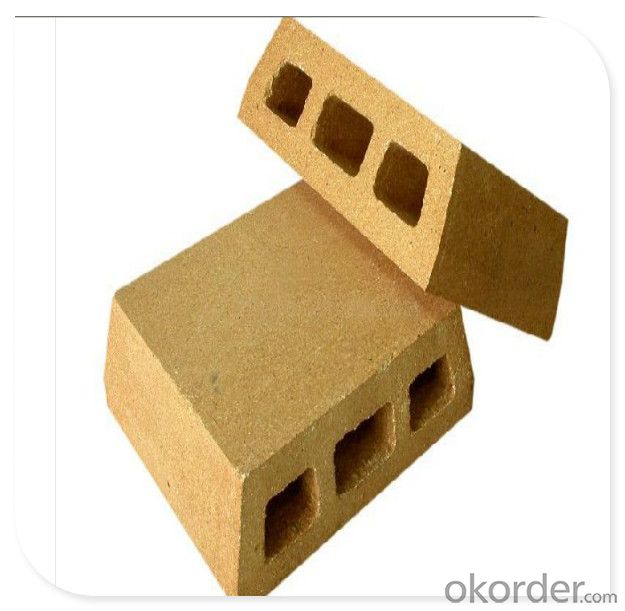

High Alumina Refractory Brick for Hot Blast Stove&Blast Furnace&Lime Kiln

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 pc

- Supply Capability:

- 50000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

High Alumina Refractory Brick for Hot Blast Stove&Blast Furnace&Lime Kilny

Feature:

1. bricks are made from high quality bauxite

2. dry pressed

3. burned under tunnel kiln

4. accurate dimension

5. high strength

Item | Properties | |||||

LZ-80 | LZ-75 | LZ-65 | LZ-55 | LZ-48 | ||

Al2O3 ,% | 80 | ≥75 | ≥65 | ≥55 | ≥48 | |

Refractoriness °C | ≥1790 | ≥1790 | ≥1790 | ≥1770 | ≥1750 | |

Bulk density,g/cm3 | 2.65 | 2.5 | 2.45 | 2.4 | 2.3 | |

Softening temperature under load | 1530 | ≥1520 | ≥1500 | ≥1470 | ≥1420 | |

Permanent linear change,% | 1500°CX2H | +0.1 | +0.1 | +0.1 | +0.1 | |

1450°CX2H | +0.1 | |||||

Apparent porosity,% | 22 | ≤23 | ≤23 | ≤22 | ≤22 | |

Cold Crushing strength Mpa | 55 | ≥50 | ≥45 | ≥40 | ≥35 | |

Application | All industrial furnace | |||||

Production & Quality

1.Production Process

Crushing→Mixing→Shaping→Drying→Firing→Inspection→Packing shipment

2.Quality Control

a.According to the chemical content,raw materials are classified into different levels to ensure quality of brick first.

b.During the production,every brick will be weighed twice strictly to reduce the error of weight .

c.Before delivery, the inspectors will inspect the size,appearance,physical and chemical properties of brick again in factory.

F&A

Q1.Are you a manufacture or trader?

A:To be honest we are a trader,but we have stable cooperation factories.And we can supply good pre-sale service, after-sales service.

Q2.Can we visit your company?

A:Sure,welcome at any time,seeing is believing.

Q3. Do you provide samples?

Yes, samples are available.

Q4. Do you accept OEM?

Yes, we can do OEM.

Q5.What's the MOQ of trial order?

A:No limit,We can offer the best suggestions and solutions according to your condition.

Q6.What are the payment terms?

Usually T/T,but L/C,Western Union etc are available for us.

Q7. How long is delivery time?

The delivery time will be determined according to the quantity of the order.

Q8.How are your products’ quality?

The products will be strictly inspected before shipment, so the quality could be guaranteed.

Q9.How to slove the quality problems?

A:If the products are not confirmed to customer samples or have quality problems,our compay will be responsible to make compensation for it.

Q10.What is the service life of your bricks?

A:The service life of different bricks is unlike.It also depends on your using condition and method.

Q11.How about your company's certification?

A:ISO9001 and Test Report,also we could apply other necessary certification.

- Q:Application characteristics of high alumina brick

- Thermal shock stability. In high alumina brick products, the stress concentration is due to differential expansion when the temperature of refractory brick changes. Therefore, the high aluminum brick products than clay brick products thermal shock stability is poor, general water temperature only 3 - 5 times.

- Q:What is the difference between T3 refractory bricks and high alumina refractory bricks?

- High aluminum refractory brick brick is all in one type of material classification, the material is AL2O3 high bauxite content above 55%, refractory brick by material into clay bricks, high aluminum brick brick brick corundum brick

- Q:Are there any differences between insulating bricks and refractory bricks?

- The refractoriness of insulating bricks is generally below 1400 tons, while the refractoriness of refractory bricks is above 1400 degrees. 3. density insulation bricks are generally lightweight insulation materials, the density is generally in 0.8-1.0g/cm3, and the density of refractory bricks are basically above 2.0g/cm3.

- Q:What is the difference between high alumina brick and clay brick?

- Light clay brick, refractory material is a kind of high porosity, low density, low thermal conductivity of refractory material, refractory materials called lightweight refractories, it includes insulating refractory products, refractory fiber and refractory fiber products. Heat insulation refractory material is characterized by high porosity, general 40%-85%, low volume density, lower than 1.5g/cm3, low thermal conductivity, generally lower than 1.0W (m.K). The utility model has the function of heat insulation of an industrial furnace, and can reduce the heat dissipation loss of the kiln, save energy, and can reduce the quality of the thermal engineering equipment. The mechanical strength, wear resistance and slag resistance of insulating refractory material are poor, and it is not suitable for the load-bearing structure of kiln and direct contact with slag, burden, molten metal and other parts.

- Q:What is the standard classification of high alumina bricks and high alumina bricks?

- High alumina brick is one of refractory materials. The main component of this kind of refractory brick is AL2O3. High alumina brick refractory clay brick and brick than refractoriness to high. It belongs to high refractory. High alumina brick Al2O3 more, close to the neutral refractory material, can resist acid slag and alkaline slag erosion, because it contains SiO2, so the ability of alkaline slag resistance than acid resistant slag ability is weaker.According to the number of AL2O3 content is divided into, 55,65, 75,80 and so on several grades.

- Q:How much is one ton / ton of high alumina refractory brick?

- The market price of about super high aluminium brick price at 3000 yuan / ton, a high aluminum brick at around 2500 yuan / ton, two high aluminum bricks at around 2100 yuan / ton three grade high alumina bricks at around 1850 yuan / ton for reference, choose to buy the area is not the same as the prices are not the same.

- Q:How much is one ton of high alumina refractory brick?

- Three high aluminum refractory brick Zhengzhou Kuwait is generally around 800. 32 years of experience, good.

- Q:What is the apparent porosity of high alumina brick?

- In the production of high alumina bricks in addition to the entity, there are many different sizes and shapes of different pores, pores can be divided into three categories: one side closed the other side and the outside world is called open pores, closed in the product not communicated with the outside is called closed pores, penetrating through pores called the few products.

- Q:What is the price of the latest thermal insulation material?

- Also through online pre understand the products and prices, and now have large-scale manufacturers are generally opened on the cable business. Goods than three, manufacturers on-site inspection, confirm the quality of goods after considering cooperation.

- Q:What are the common thermal insulation materials for thermal conductivity?

- The vacuum heat insulation plate is a kind of high efficiency thermal insulation board made of inorganic fiber core material and high resistance gas composite film. It is made of vacuum encapsulation technology and covered with special interface mortar.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

High Alumina Refractory Brick for Hot Blast Stove&Blast Furnace&Lime Kiln

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 pc

- Supply Capability:

- 50000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords