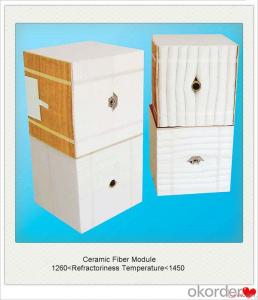

High Alumina Content Refractory Ceramic Module

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description

ceramic fibre module adopt high quality ceramic fibre blanket, which is made up to compression module after folding, compression, packing

module can choose kinds combination of anchor and furnace body, installation method is so simple that quicken the speed of furnace lining construction largely

After installation, the bandaging are cut and the modules and so to form an integrated insulating lining.

The anchor system in remote from he module hot face, maintaining the metal components at a relatively low temperature

Features

The anchorage on the back allows for both in-line and parquet installation.

The decompression of the blanket folds gives tightly sealed intermodular joints with both configurations

The resilient blanket is resistant to mechanical damage

Low thermal conductivity give high thermal efficiency

Total resistance to thermal shock

No drying or curing required – so available for production operation immediately after installation

The anchor is remote form the module hot face

Typical Applications

Heat treatment: annealing furnace, tempering furnace, soaking pit, etc

Ceramic: whiteware, sanitary ware and brick firing tunnel and intermitted kiln.

Iron and Steel: Transfer ladle lids, soaking pit covers, reheating furnace, continuous annealing furnaces, lift-off furnaces

Petrochemical: ethylene pyrolysis furnace,reformers,atmosphere / reduced pressure furnace,ductwork pyrolysis heaters

Aluminium: Soaking pits and covers, bale out furnaces, homogenizing and ductwork

Utilities: waste heat recovery units, combustion chambers and boiler ductwork

- Q:Ceramic fiber module or refractory brick for hot galvanizing furnace body insulation? Who gave me an analysis?

- Hot galvanizing furnace is usually burning natural gas to the new pot heating, natural gas heating will produce higher wind speed to 21m/s, so the hot galvanized furnace insulation materials have certain requirements. The hot galvanizing furnace before 2013 is usually made of refractory bricks for heat preservation, and the energy saving effect is common.

- Q:How to install refractory fiber?

- Dry plate is used to spray adhesive mechanical pressing low density has good elasticity and flexibility is usually used for wet insulation sealing by washing vacuum shaping mould plate of high density, hardness, mechanical processing can be generally used as fireproof heat insulation is very good Oh, you can try

- Q:Ceramic fiber plate and aluminium silicate plate are chosen as lining materials

- Ceramic fiber surface roughness, accurate size, good toughness, can be arbitrarily cut, good insulation effect; ceramic fiber board can be distinguished according to the temperature, heat is widely used in the back lining of industrial furnace and kiln temperature, kiln is an important guarantee for energy saving, high yield and quality factors of A.

- Q:What is the refractory temperature of the ceramic fiber cloth?

- Non-toxic, harmless, no adverse effects on the environment; the scope of application of ceramic fiber cloth: all kinds of high temperature furnace, thermal insulation pipes and containers; door, valve, flange sealing, fire door, fire shutter door curtain, high temperature sensitive materials; engine and instrument cable insulation, fireproof coating material, fireproof material; thermal insulation cover with cloth, high temperature expansion joint filler, flue lining; high temperature resistant safety products, fire service, high temperature filtration, sound and other fields instead of asbestos

- Q:Can ceramic fibers be spun? Hope experts answer, if you are the one!

- Ceramic fiber can be spun, but certain auxiliary materials must be added. The ceramic fiber is soft, and the resistance and non - fiber of the ceramic fiber must be guaranteed.

- Q:What about the composite reflecting insulation board and ceramic fiber?

- The maximum temperature of ceramic fiber heat insulation material can be up to 1400 degrees. Although the highest use temperature of ceramic fiber is higher than that of Tianjin solid composite reflecting insulation board, the heat insulation effect is far worse.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

High Alumina Content Refractory Ceramic Module

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products