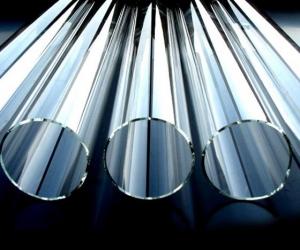

High AI2O3 Ceramic Tubes

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Piece pc

- Supply Capability:

- 10000 Pieces per Month pc/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

High AI2O3 Ceramic Tubes

1.Material: 95% alumina ceramic

2.Specification can be customed

3.High quality

High AI2O3 Ceramic Tubes

| Material | 85 Al2o3 | 90 Al2o3 | 95 Al2o3 | 99 Al2o3 |

| Al2o3 | 85% | 90% | 93% | 99.30% |

| Fe2o3 | ≤ 1.0 | ≤ 0.5 | ≤ 0.5 | ≤ 0.3 |

| Desnsity: g / cm3 | 3.4 | 3.5 | 3.6 | 3.85 |

| Vickers Hardness | ≥ 8.6 | ≥ 8.8 | 9 | 9 |

| Water Absorption:% | ≤ 0.2 | ≤ 0.1 | ≤ 0.085 | ≤ 0.01 |

| Refractoriness:°C | 1580 °C | 1600 °C | 1650 °C | 1800°C |

| Flexural Strength:Mpa | 180 | 200 | 240 | 280 |

Wear Rate( at room temperature,

erosion, 100 grinding)% | ≤ 3 | ≤ 2.5 | ≤ 1 | ≤ 0.5 |

| Dimension | Outer dia. mm | Inner dia.mm | Length mm | Remark | |

| Item | |||||

| Thermocouple protection tube | 7-120 | 1-110 | 10-2000 |

If you need others,we

can customize for you. | |

| Insulated tube | Single hole | 2-120 | 1-110 | 10-2000 | |

| (inner core) | Double holes | 1-10 | 0.4-2 | 10-2000 | |

| Four holes | 2-10 | 0.5-2 | 10-2000 | ||

| Feature | Application | Main usage |

| 1.Great mechanical strength |

Electric appliance industry

Automotive industry |

1.Heat treatment furnace

and toughened furnace |

| 2.High softening temperature | ||

| 3.Good resistance to thermal impact | ||

| 4.Small thermal expansion coefficient |

Mechanical industry

Engineer industry |

2.Inner liner tube and heating

tube in electric furnace |

| 5.Good chill and abrupt heat properties | ||

6. Resistance to acid and alkali corrosion |

- Q:Quartz products are mainly used in photovoltaic and semiconductor industry which links, please expert pointing!

- Quartz can be used in many industriesYou should say that the PV and semi industry should be polycrystalline silicon or monocrystalline siliconThe manufacture of quartz products is first made into quartz powder, which can be used as quartz glass tubes, quartz plates, crucibles and so onThe crucible is very demanding, because it's Gao ChunshaThe crucible is stable because of the physical properties of the quartz material and can be used to refine polycrystalline silicon - monocrystalline siliconThe industry itself has recently come into contact, and it should be said that the prospects for development are good

- Q:What are the sizes of arc quartz crucibles?

- HF can not contact, high temperature, easy and caustic alkali carbonate reaction and alkali metal. 3. quartz crucibles are suitable for melting samples with K2S2O7, KHSO4 as flux, and using Na2S207 (first drying at 212 degrees) to treat samples with flux.

- Q:Can porcelain crucible, quartz crucible and alumina crucible be filled with aluminium hydroxide?

- The translucent quartz crucible made by arc method is the basic material for drawing large diameter monocrystalline silicon and developing large-scale integrated circuit

- Q:Is the quartz crucible drawn by monocrystalline silicon disposable?

- Yes, once a quartz crucible has been used, it will crack or break even after high temperature and cooling. And the single crystal drawing requires a high-purity quartz crucible.

- Q:The quartz ceramic crucible melting quartz crucible

- Because of the use of extremely harsh conditions, the crucible of purity, strength, appearance defects, internal quality, high temperature performance, thermal shock stability and dimensional accuracy has very strict requirements.

- Q:What happens when carbon carbon crucibles are cracked?

- After a long period of use, its silicon vapor corroded the edges of the carbon and carbon parts;

- Q:What crucible is used to melt solid caustic soda?Why not quartz crucibles?

- Do not use ceramic crucibles or quartz crucibles. Use metal crucibles, preferably with silver cruciblesThe quartz crucible reacts to form the sodium silicate (2NaOH+SiO2=Na2SiO3+H2O) ceramic crucible

- Q:At present, the quartz crucible used in Czochralski silicon is used to make use of barium coating, but how does the oxygen content rise when the coating react with the silicon melt?

- The coating has the effect of increasing the crystallization rate without increasing the cost and is more impractical

- Q:How much fire resistance is quartz crucible?

- The long-term use of the crucible temperature is 1100 degrees, but pulling when the stone is outside, so can be used for a long time. The crucible will deform about 1300 degrees. 1100 degrees without deformation.

- Q:Can quartz crucibles be used as ROI for fluorine compounds?

- Quartz crucible can be used below 1650 degrees. It is divided into two kinds: transparent and opaque. The translucent quartz crucible fabricated by arc method is a basic material for developing large scale integrated circuits.

We are one of the most leading and advanced ceramic material companies in China.

We strictly comply with ISO9001 quality management system. Our products are widely used in aerospace, mining machinery, lift, power, paper making, laboratory, nonferrous metal processing, electronics processing, textile machinery and other industries, we provide wholesale and retail services.

1. Manufacturer Overview |

|

|---|---|

| Location | Shanghai,China |

| Year Established | 2010 |

| Annual Output Value | |

| Main Markets | North America South America Eastern Europe Southeast Asia Africa Mid East Eastern Asia Western Europe Central America Northern Europe Southern Europe |

| Company Certifications | ISO 9001:2000 |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | 1% - 10% |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | Below 1,000 square meters |

| No. of Production Lines | 4 |

| Contract Manufacturing | OEM Service Offered Design Service Offered |

| Product Price Range | |

Send your message to us

High AI2O3 Ceramic Tubes

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Piece pc

- Supply Capability:

- 10000 Pieces per Month pc/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

New products

Hot products

Related keywords