HEFEI SUDA newest engraving machine on promotion

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 30 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

| Condition: | New | CNC or Not: | CNC | Place of Origin: | Guangdong China (Mainland) |

| Brand Name: | LuckBerry | Model Number: | R-1618*6 | Voltage: | AC380V/50Hz |

| Power(W): | 1.5kw/2.2kw | Dimension(L*W*H): | 1500*1300*180mm | Weight: | 1500kg |

| Certification: | CE/ISO | Warranty: | 12months | After-sales Service Provided: | Engineers available to service machinery overseas |

| Net weight: | 1000kg | Spindle power: | 1.5KW | Spindle speed: | 6000-24000rpm/min |

| Working area: | 1600*1800*180mm | Diameter of cutter: | 3.175-16mm | Overall size: | 1600*1800*1500mm |

| Spindle quantity: | 6pcs | Spindle mode: | Water-cooling spindle | Max working speed: | 8m/min |

Packaging & Delivery

| Packaging Detail: | Standard Package: Thickness PE Foam inside ,poly film outside, wooden pallet is optional. |

| Delivery Detail: | 30 days after receiving down payment |

Specifications

R-1618*6 CNC Engraving Machine

1.Max working speed:8m/min

2.Spindle power:1.5KW water-cooling

3.Spindle speed:6000-24000rpm

R-1618*6-SG CNC Engraving Machine

Product Description

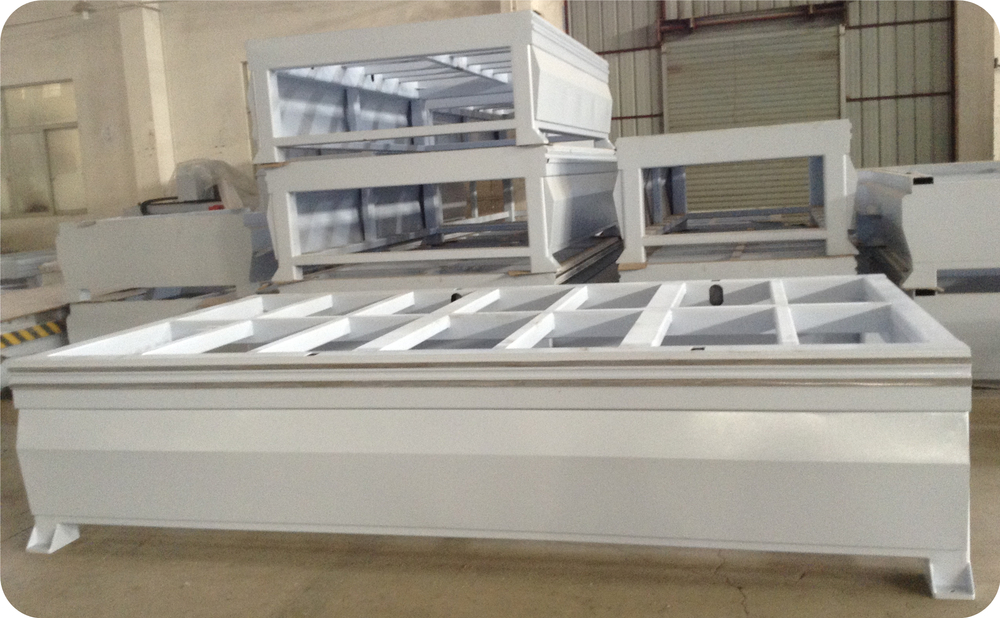

♦ Reference Picture of R-1618*6 CNC Engraving Machine :

♦ Specification of R-1618*6 CNC Engraving Machine :

Configuration of R-1618*6 CNC Engraving Machine:

| NO. | Detail Pictures | Items | Brand |

| 1 |  | Machine Structure | Cast steel body with aging & tempering treatment, solid and durable |

| 2 |

| T-Slot Worktable | T-Slot worktable clamp the workpiece directly, suit for small piece, cutting and hollow out processing. |

| 3 |

| Water-cooling Spindle | 6pcs * 1.5kw Hanqi Water-cooling Spindle

Strong Carving power, high precision, longer service life; Adopt grinding technology, can improve the motor concentricity, prolong service life.

|

| 4 |

| Driving System | Leadshine Motor set with imported precision bearing, large torque, long working hours.

X,Y,Z axis drived by Leadshine driver, high resolution and positioning accuracy. |

| 5 |

| Transimission |

X,Y,Z axis adopt Taiwan AHK high precision preload anti-backlash ball screw, screw nut with tracking airtight dust removal device, guarantee the machine precision and service life.

|

| 6 |  | Guide Rail | Y axis adopt Taiwan Hiwin 20mm guide rail; X axis and Z axis adopts Taiwan Hiwin 20mm guide rail, adding scraping devices external and dust proof protection, extending the service life of the guide rail effectively. |

| 7 |

|

Electrical Component Breaker

|

Germany Schneider

|

| 8 | Frequency Inverter |

Sunfar Frequency Inverter

| |

| 9 | Electrical Compnent Cable | Special shielded cable drag chain special high flexible, can bend millions of times, drag chain support 150 degrees bend, effectively protect the cable. | |

| 11 | Approaching Sensor Switch | Dust proof, waterproof & antiseptic (3 pcs for X,Y and Z axis) | |

| 13 | Control System | Weihong System, visualization operation, real- time simulation, pretreatment ability | |

| 14 | Software Available | Artcam, Alphacam, Type 3, etc. CAD/CAM software compatible, identify G code, *.NC. | |

| 15 | Collect | 6 peice |

Workshop:

- Q:How should the engraving machine adjust the diagonal line?

- The correct way is to loosen the screws on the Longmen according to the size of the error before and after walking machine and then tightly fixed screw die in Longmen so as to ensure that after the Longmen is not in the tilt (this method is only applicable to steel structure of Longmen aluminum plate Longmen) to loosen the slider and the gear box according to the size of the error before and after the transfer, if the screw is drive machine this problem you need to replace the nut, Longmen plate, screw machine is new if this problem was simply to return, this machine can not be used.

- Q:Who knows extension carving multi head rotary woodworking engraving machine graphics what software is used?

- Woodworking engraving machine CNC stereo in addition to OUKE, Beijing, NC, seems to have one, the other is imitation could not guarantee the quality of de.

- Q:Engraving machine model is determined by what, such as the new CX1325 woodworking machine, screw machine, CX1325 advertising engraving machine, two are CX1325, the same?

- The so-called advertising machine, that is commonly referred to as screw drive engraving machine, woodworking machine is rack drive, woodworking machine prices slightly higher, but good performance, fast work! Screw machine is almost obsolete, not recommended to buy!

- Q:How to choose your own woodworking engraving machine?

- Choose the right type of woodworking engraving machineSmall advertising signs shop for the first time, the main production of three-dimensional characters, lights, crystal, double color, chest cards and other purposes, should buy ad grade. Generally speaking, the engraving machine is larger than 1200mm, and is not suitable for engraving fine shade and so on. It is suitable for sawing and making some large flat. In the 1200mm format and the following is a universal engraving machine, can be used as a double plate such as fine, and can be used to do menial work saw the word. For the machining of cylindrical or other special-shaped workpiece, as the need to install some jigs or rotating axis, which shows the high Z shaft column, the table to the head space is large, so you can use the special machine. If the seal shop is specially engraved seal, it can be equipped with a small laser engraving machine.

- Q:Which brand of engraving machine is good, mainly carpentry?

- First look at the engraving machine format size. The customer should according to the needs of the business and financial situation, choose the suitable type of engraving machine and the size of their own power. So several models of demand for large format engraving machine is suitable for the customer.

- Q:Which is the best woodworking engraving machine? Both at home and abroad!

- Buy engraving confidential, look at the configuration, the degree of automation, and that is to see whether the after-sales service can solve the problem on time. So as not to delay the equipment work stroke!

- Q:Woodworking engraving machine carved PVC word lines have no vertical edges, what is the reason

- No vertical edge because of clockwise

- Q:How to judge the temperature of the stepper motor of woodworking engraving machine overheating?

- Actually, the question is simple. Stepper motor heating reasonable scale, motor heating promised to what extent, mainly depends on the internal insulation level of the motor. Internal insulation can be damaged at high temperatures (above 130 degrees). Therefore, the motor does not damage if it does not exceed 130 degrees inside. We can't measure the internal temperature accurately, but we can measure the surface temperature of the motor. When the internal temperature is 130 degrees, the outside will be around 90 degrees. Therefore, the stepper motor surface temperature is normal at 70-80 degrees.

- Q:Can a woodworking engraving machine be the same as a relief machine?

- Professional relief machines and woodworking engraving machine, the effect will certainly be different,Relief machines are generally used three screw drive shaft, woodworking engraving machine is the basic rack drive, the precision is mainly different, but there are a lot of relief as the woodworking engraving machine machine to sell, if you do not ask for much, or the right to use the.

- Q:What is the production flow of the woodwork door and woodworking engraving machine?

- Is expected to open with the cabinet body, door material is more diverse, on the plate cutting, cutting with high-end or low-end according to the laser cutting machine, hand push table saw, integrated processing center equipment with some materials according to.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

HEFEI SUDA newest engraving machine on promotion

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 30 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords