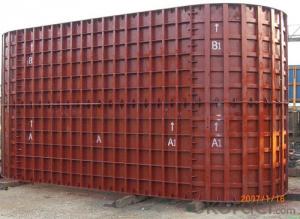

Heavy Steel Formwork for Dam Construction with Anti-Corrosion Paint

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 150 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction for Steel Formwork :

Steel Formwork:used in highway,railway,bridge,tunnel and shearing wall,etc.Our company CNBM which is one of the largest State-Owned Enterprises in China which established in 1984 , has gained the confirmation from the specialist of China Architecture Scence Institute, and has been used by many building operation units and has been highly praised.In 2014, the total turnover volume of CNBM exceeds US$410 billion dollars with a total staff of 180,000. CNBM is listed in the World Top 500 Enterprises !

Characteristic for Wholly Steel Formwork :

1. High Smooth Surface

2. Convex ling for Edge Rib

3. Specialized Connection Pin for Edge Rib Connection

4. High Stiffness for Steel Surface

5. Light Weight for saving producing cost

6. Fast Separate and Easy transport

7. Recycling using

8. Scientific and Reasonable design to meet different working condition

Parameter and Specification :

Code | Size (mm) | Weight (KG) | Code | Size (mm) | Weight (KG) |

P12021 | 1200*2100*55 | 102.96 | P4018 | 400*1800*55 | 28.3 |

P12018 | 1200*1800*55 | 88.4 | P4015 | 400*1500*55 | 23.8 |

P12015 | 1200*1500*55 | 74.15 | P4012 | 400*1200*55 | 19.1 |

P12012 | 1200*1200*55 | 60.11 | P4009 | 400*900*55 | 14.6 |

P10018 | 1000*1800*55 | 76.01 | P4007 | 400*750*55 | 12.3 |

P10015 | 1000*1500*55 | 63.96 | P4006 | 400*600*55 | 9.95 |

P10012 | 1000*1200*55 | 60.11 | P3018 | 300*1800*55 | 20.7 |

P10009 | 1000*900*55 | 39.32 | P3015 | 300*1500*55 | 17.4 |

P9018 | 900*1800*55 | 70.89 | P3012 | 300*1200*55 | 14 |

P9015 | 900*1500*55 | 59.47 | P3009 | 300*900*55 | 10.7 |

P9012 | 900*1200*55 | 48.03 | P3007 | 300*750*55 | 8.8 |

P7518 | 750*1800*55 | 57.8 | P3006 | 300*600*55 | 7.3 |

P7515 | 750*1500*55 | 48.47 | P3004 | 300*400*55 | 5.46 |

P7512 | 750*1200*55 | 39.16 | P2515 | 250*1500*55 | 15.17 |

P7509 | 750*900*55 | 29.85 | P2512 | 250*1200*55 | 12.24 |

P7507 | 750*750*55 | 24.81 | P2509 | 250*900*55 | 9.32 |

P6018 | 600*1800*55 | 43.1 | P2507 | 250*750*55 | 7.71 |

P6015 | 600*1500*55 | 36.3 | P2506 | 250*600*55 | 6.39 |

P6012 | 600*1200*55 | 31.7 | P2015 | 200*1500*55 | 11.6 |

P6009 | 600*900*55 | 23.9 | P2012 | 200*1200*55 | 9.4 |

P6007 | 600*750*55 | 18.55 | P2009 | 200*900*55 | 7.1 |

P6006 | 600*600*55 | 16.25 | P2007 | 200*750*55 | 5.9 |

P5018 | 500*1800*55 | 36.27 | P2006 | 200*600*55 | 6.39 |

P5015 | 500*1500*55 | 30.15 | P2004 | 200*450*55 | 3.64 |

P5012 | 500*1200*55 | 25.55 | P1515 | 150*1500*55 | 9.5 |

P5009 | 500*900*55 | 20.38 | P1506 | 150*600*55 | 4 |

P5007 | 500*750*55 | 15.48 | P1504 | 150*450*55 | 2.98 |

P5006 | 500*600*55 | 13.58 | P1015 | 100*1500*55 | 7.5 |

Code | Size (mm) | Weight (KG) |

P1012 | 100*1200*55 | 6.9 |

P1009 | 100*900*55 | 4.6 |

P1007 | 100*750*55 | 3.8 |

P1006 | 100*600*55 | 3.1 |

P1004 | 100*450*55 | 2.33 |

E1515 | 150*150*1500 | 15.2 |

E1512 | 150*150*1200 | 12.26 |

E1509 | 150*150*900 | 9.34 |

E1507 | 150*150*750 | 7.77 |

E1506 | 150*150*600 | 6.46 |

E1504 | 150*150*450 | 4.87 |

E1015 | 100*150*1500 | 13.13 |

E1012 | 100*150*1200 | 10.61 |

E1009 | 100*150*900 | 8.07 |

E1006 | 100*150*600 | 5.44 |

Y1018 | 100*150*1800 | 14.56 |

Y1015 | 100*150*1500 | 12.29 |

Y1012 | 100*150*1200 | 9.72 |

Y1009 | 100*150*900 | 7.46 |

Y1007 | 100*150*700 | 6.19 |

Y1006 | 100*150*600 | 5.19 |

Y1004 | 100*150*450 | 3.92 |

J0018 | 50*50*1800 | 4.34 |

J0015 | 50*50*1500 | 3.7 |

J0012 | 50*50*1200 | 2.94 |

J0009 | 50*50*900 | 2.3 |

J0007 | 50*50*750 | 1.9 |

J0006 | 50*50*600 | 1.5 |

J0004 | 50*50*450 | 1.13 |

FAQ :

1. Who are we ?

We , CNBM , are a State-Owned Enterprise which established in 1984 , have 32 years experience ,enjoy high reputation .

2. Our Advantage :

Customized products , we have our own R&D department , we can design the drawing and suggest the suitable solution for your project .

3. Our after-Sales Service :

The international Sales Manager and Engineer can go to your job site for work direction and help you deal with your project .

Factory Photos :

- Q:How does steel formwork affect the overall construction material waste reduction?

- Steel formwork is a construction technique that involves using steel panels and frames to create temporary molds or structures into which concrete is poured. This method offers several advantages over traditional timber formwork, one of which is its positive impact on overall construction material waste reduction. Firstly, steel formwork is highly durable and can be reused multiple times, whereas timber formwork often needs to be replaced after a few uses due to wear and tear. This means that steel formwork significantly reduces the amount of material waste generated during the construction process, as there is minimal need for regular replacements. Additionally, steel formwork is more precise and accurate compared to timber formwork, resulting in less waste of concrete. The precise measurements and tight joints of steel formwork ensure that concrete is poured and set correctly, minimizing the need for additional material to fill gaps or rectify errors. This leads to a reduction in material waste, as less concrete is wasted during the construction process. Moreover, steel formwork is easily adaptable and adjustable to different shapes and sizes, allowing for efficient and flexible use on various construction projects. The versatility of steel formwork means that it can be reused for different structures or modified to suit changing requirements. This adaptability further reduces material waste, as the same formwork can be utilized for multiple projects or repurposed as needed. Furthermore, steel formwork is known for its high strength and load-bearing capacity, enabling it to withstand heavy concrete pressure without deformation or damage. This strength allows for taller and more complex structures to be constructed using steel formwork, reducing the need for additional materials such as support beams or columns. By eliminating the need for these extra materials, steel formwork contributes to a significant reduction in overall construction material waste. In summary, steel formwork positively impacts overall construction material waste reduction through its durability, precision, adaptability, and strength. By minimizing the need for regular replacements, reducing concrete waste, allowing for reuse and adaptability, and eliminating the need for additional materials, steel formwork plays a crucial role in promoting sustainable construction practices and reducing environmental impacts.

- Q:Can steel formwork be used for both interior and exterior concrete elements?

- Steel formwork is suitable for both interior and exterior concrete elements. Its versatility makes it applicable to different construction projects. Furthermore, steel formwork is known for its durability, strength, and ability to withstand the pressure exerted by wet concrete. It also provides exceptional dimensional accuracy and ensures smooth and uniform concrete surfaces. Whether constructing interior slabs, walls, or exterior foundations, columns, or beams, steel formwork is a dependable option for both interior and exterior concrete elements.

- Q:Can steel formwork be used for both manual and mechanical concrete pouring?

- Yes, steel formwork can be used for both manual and mechanical concrete pouring. The strength and durability of steel make it suitable for various construction methods, allowing for flexibility in concrete pouring techniques.

- Q:Can steel formwork be used for both residential and commercial renovations?

- Yes, steel formwork can be used for both residential and commercial renovations. Steel formwork is known for its durability and strength, making it suitable for various construction projects. Whether it is a residential renovation such as adding an extension or a commercial renovation like remodeling an office space, steel formwork can provide the necessary support and stability during the construction process. Additionally, steel formwork can be easily customized and adjusted to fit different project requirements, making it a versatile option for both residential and commercial renovations.

- Q:How does steel formwork ensure accurate concrete dimensions and alignment?

- Steel formwork is a popular choice in construction projects due to its ability to ensure accurate concrete dimensions and alignment. This is achieved through various features and advantages offered by steel formwork. Firstly, steel formwork is highly durable and rigid, providing a stable structure for pouring and shaping concrete. Its strength prevents any deformation or movement during the pouring process, which is crucial for maintaining accurate dimensions and alignment. Unlike other formwork materials, such as wood, steel does not expand or contract significantly due to temperature changes or exposure to moisture, ensuring dimensional stability. In addition, steel formwork is designed and manufactured with precision, allowing for precise control over the shape, size, and alignment of the concrete structure. The use of computer-aided design (CAD) and advanced manufacturing techniques ensures that the steel formwork is accurately fabricated according to the required specifications. This precision eliminates any human errors in measurement and construction, resulting in accurate concrete dimensions and alignment. Furthermore, steel formwork offers flexibility in terms of customization. It can be easily adjusted and modified to accommodate various shapes, sizes, and architectural designs. This adaptability allows for accurate concrete dimensions and alignment, even for complex structures or intricate architectural elements. Moreover, steel formwork provides a smooth and level surface for the concrete to be poured against. This smoothness ensures that the concrete adheres uniformly to the formwork, preventing any irregularities or inconsistencies in the final structure. The tight joints and connections of steel formwork also minimize any leakage or seepage of concrete, ensuring that the poured material is contained within the desired dimensions. Overall, steel formwork ensures accurate concrete dimensions and alignment through its durability, precision, flexibility, and smoothness. By providing a stable and precise framework for pouring concrete, steel formwork eliminates any errors or deviations and guarantees a high-quality finished product.

- Q:Is steel formwork suitable for projects with limited access?

- Yes, steel formwork is suitable for projects with limited access. Steel formwork is known for its strength and durability, allowing it to be easily transported and assembled in confined spaces. Additionally, steel formwork can be customized to fit specific project requirements, making it an ideal choice for projects with limited access.

- Q:What are the common safety guidelines when working with steel formwork in confined spaces?

- When working with steel formwork in confined spaces, it is crucial to follow certain safety guidelines to ensure the well-being of the workers involved. Here are some common safety guidelines to consider: 1. Conduct a thorough risk assessment: Before starting any work in a confined space, it is important to assess the potential hazards and risks associated with the task. This assessment should include identifying potential dangers such as inadequate ventilation, limited access, or the presence of hazardous gases. 2. Adequate ventilation: Confined spaces often have limited air circulation, which can lead to a buildup of toxic gases or lack of oxygen. Ensure that the area is properly ventilated before entering and continuously monitor air quality throughout the work. 3. Use appropriate personal protective equipment (PPE): Workers should always wear the necessary PPE, including safety helmets, goggles, gloves, and appropriate respiratory protection. The specific PPE requirements may vary depending on the nature of the confined space and associated hazards. 4. Implement proper lighting: Confined spaces are often poorly lit, making it difficult to see potential hazards and work safely. Adequate lighting should be provided to ensure clear visibility and reduce the risk of accidents. 5. Implement proper entry and exit procedures: Establish clear entry and exit procedures for workers entering and leaving the confined space. This should include proper signage, secure barriers, and a designated person responsible for monitoring and controlling access. 6. Ensure proper communication: Establish a reliable system for communication between workers inside and outside the confined space. This may involve the use of two-way radios, hand signals, or other means of communication to prevent isolation and enable prompt assistance if needed. 7. Regularly inspect equipment and formwork: Prior to starting work, inspect the steel formwork and associated equipment for any damage or defects. Any issues should be promptly addressed to prevent accidents or structural failures. 8. Provide proper training: Workers involved in working with steel formwork in confined spaces should receive appropriate training on safety procedures, hazard recognition, emergency response, and proper use of equipment. Regular training updates should also be conducted to ensure workers remain aware of safety practices. 9. Establish an emergency response plan: Despite taking proper precautions, emergencies can still occur. Establish an emergency response plan that includes procedures for evacuation, rescue, and medical assistance. Ensure that all workers are familiar with the plan and conduct regular drills to practice these procedures. 10. Regularly review and update safety procedures: Safety procedures should be regularly reviewed and updated to incorporate new regulations, industry best practices, or lessons learned from previous incidents. Continuous improvement and monitoring of safety measures are essential to ensure a safe working environment. Remember, working in confined spaces with steel formwork can present significant risks. By following these common safety guidelines and promoting a safety-conscious culture, the risk of accidents and injuries can be minimized, ensuring a safer working environment for all.

- Q:Are there any specialized tools or equipment required for steel formwork?

- Specialized tools and equipment are necessary for steel formwork. Some commonly used tools are as follows: 1. To secure the steel formwork panels together and maintain stability and alignment, formwork clamps are utilized. 2. Formwork ties are employed to hold the formwork panels in place and prevent any movement while concrete is being poured and cured. 3. Formwork brackets are utilized to evenly distribute the load and provide support to the formwork panels. 4. Formwork shuttering magnets are utilized to securely hold the formwork panels in place, establishing a strong connection. 5. Formwork jacks are utilized to adjust the height of the formwork panels, enabling precise leveling and alignment. 6. Formwork hangers are employed to suspend the formwork panels from overhead structures, enhancing stability and support. 7. Formwork props are utilized to vertically support the formwork panels, ensuring their position during the concrete pouring process. 8. Formwork vibrators are used to eliminate air bubbles and guarantee proper compaction of the concrete within the formwork. Proper and appropriate use of these specialized tools and equipment is crucial to maintain the structural integrity and quality of the steel formwork.

- Q:What are the common quality control measures for steel formwork?

- Common quality control measures for steel formwork include: 1. Visual Inspection: This involves a thorough examination of the steel formwork to check for any visible defects or damage. Any signs of cracks, dents, or deformations should be identified and addressed. 2. Dimensional Accuracy: The dimensions of the steel formwork, such as the length, width, and height, should be measured and compared to the specified requirements. Any deviations from the required dimensions should be corrected. 3. Material Testing: Steel formwork should undergo material testing to ensure that it meets the required standards and specifications. This may involve testing the tensile strength, yield strength, hardness, and chemical composition of the steel. 4. Welding Inspection: If the steel formwork is welded, the quality of the welds should be inspected. This includes checking for proper penetration, fusion, and the absence of any defects like cracks or porosity. Non-destructive testing methods like ultrasonic or radiographic testing can be employed to ensure the integrity of the welds. 5. Surface Coating Inspection: The surface coating of the steel formwork, such as paint or galvanized coating, should be inspected for its thickness, adhesion, and uniformity. This ensures protection against corrosion and enhances the durability of the formwork. 6. Load Testing: Steel formwork should be subjected to load testing to evaluate its structural integrity and load-bearing capacity. This involves applying a known load to the formwork and monitoring its response to ensure it can safely support the required loads during construction. 7. Documentation and Record Keeping: Quality control measures should be documented and records should be maintained for future reference. This includes recording the inspection results, material test reports, and any corrective actions taken. These quality control measures help to ensure that steel formwork meets the required standards, specifications, and safety regulations, ultimately ensuring the structural integrity and performance of the formwork during construction.

- Q:Can steel formwork be used for fire-resistant concrete structures?

- Fire-resistant concrete structures can indeed utilize steel formwork. Steel possesses exceptional strength and heat resistance, rendering it an optimal choice for constructing formwork in such cases. Furthermore, steel formwork presents several benefits, including longevity, reusability, and effortless assembly and disassembly. By offering essential support and containment during the pouring and curing processes, it guarantees the integrity and safety of the structure in the event of a fire. Nevertheless, it is crucial to acknowledge that the fire resistance of the concrete itself is contingent upon factors like mix design, aggregate selection, and thickness, rather than relying solely on the formwork material.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Heavy Steel Formwork for Dam Construction with Anti-Corrosion Paint

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 150 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords