Heavy Duty Prop 3.0M-5.0M Q235 Steel Prop Standard EN1065 CNBM

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 pc

- Supply Capability:

- 30000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details of Heavy Duty Prop 3.0M-5.0M Q235 Steel Prop Standard EN1065

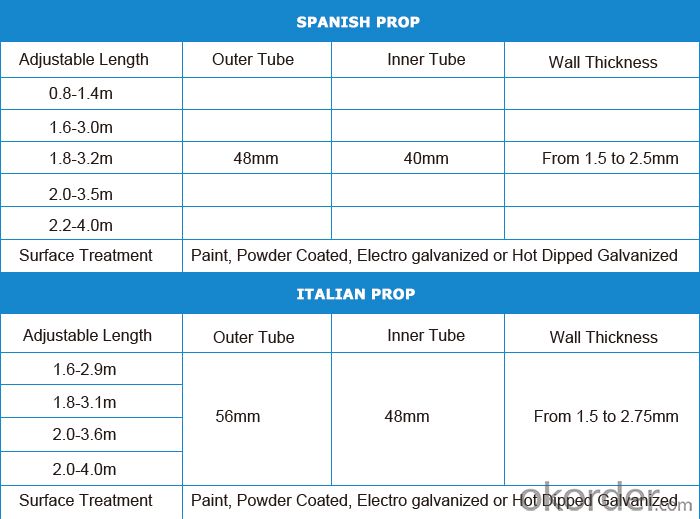

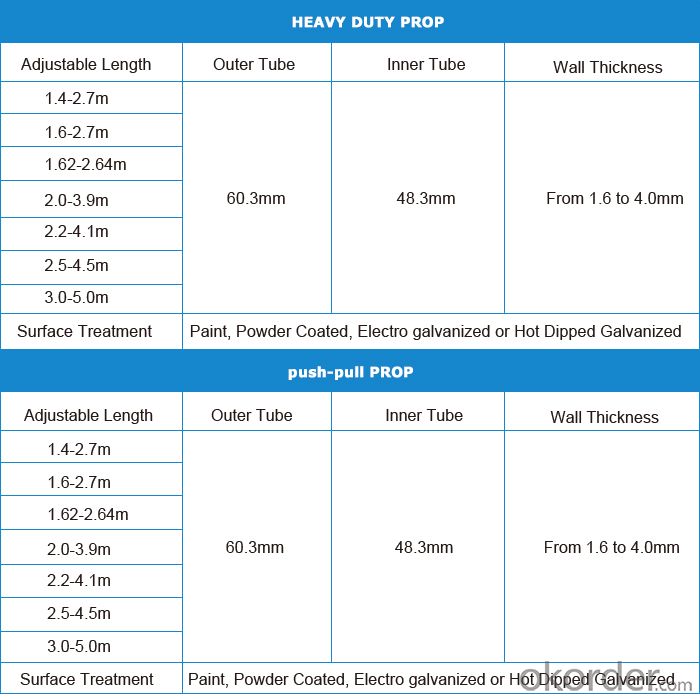

Material :Q235 carbon steel

Surface treatment :painted/electro-galvanized/power-coating/hot dipped galvanized

Standard: EN1065

Thickness :1.6mm-3.0mm

Descriptions of Heavy Duty Prop 3.0M-5.0M Q235 Steel Prop Standard EN1065

Our steel prop is a very Economical & practical & simple & easy installation bracing member with very high bearing capacity.

The steel props are very good vertical support suitable for various shaped slab formworks and popularly used in vertical structure support system. 4000 tons annual output.

Our steel prop used as a formwork is with very high bearing capacity.

Steel prop's vertical load capacity (within 4 meters length) can reach 10 KN.

Nuts are strictly manufactured according to national standard and with 10 tons load capacity.

Basic load capacity ≥15KN tested by national authorized organizations.

Shortening working hours & high efficiency

Firm structured props with high strength bearing capacity perfectly resisted the external shocks.

Galvanized prop surface process

Practical & Economical steel props make the buyers feel safe.

FAQ

1. What is considerations of Scaffolding installation?

There must be a fire protection measures and specialist care, safety personnel patrol inspection when electricity, gas welding work on the scaffold,

(1) scaffold frontage hurtful to prevent falling objects protection is required.

(2) During take down the scaffolding, fencing and warning signs should be set up on the ground, prohibit others person besides the operator

2.What are the certifications of your products?

Certified by SGS, BS1139, EN74, Local Test Report.

3. How long is the warranty period for your product?

Our products warranty is 2 years.

- Q:What are the safety requirements for the dismantling of construction scaffolding

- (5) remove the material, structural parts, etc., it is strictly prohibited to throw down, the use of rope tied firmly slow down, or with a crane, basket and other means of transport to the ground.(6) the scaffolding removed, should make clear the workplace after work, all materials and components should be neatly stacked, safe and stable, and timely transport.

- Q:What is the difference between Scaffolding and Zone of Proximal Development?

- Taken from okorder: Vygotsky believed that when a student is at the zone of proximal development for a particular task, providing the appropriate assistance (scaffolding) will give the student enough of a boost to achieve the task. Once the student, with the benefit of scaffolding, masters the task, the scaffolding can then be removed and the student will then be able to complete the task again on his own.

- Q:Okay, quick question. I dropped into a couple of piercing studios yesterday to inquire about getting a scaffold done. Both places informed me that it's not a good idea to have it pierced with a bar straight off, as the pressure from the jewellery combined with the swelling when first pierced can seriously slow down the healing rate. Is this true? The second place said they will pierce both holes with rings, and these can be changed to a bar after around 6 to 8 weeks.Is this the best option? Thanks for any replies.

- Having one bar can definitely put a lot of pressure on the piercing but it's the best way to go about getting an industrial piercing. It can be a difficult piercing to heal is all. If you get two rings it is very likely that one will slightly migrate in angle and that is going to make it impossible to properly fit a bar through the two holes. Plus, 6-8 weeks would be WAY way way too early to change a cartilage piercing. Try 6-12 months. And an industrial will never reject simply because of the bar, it will reject if it was pierced incorrectly or on someone's ear that is not anatomically correct for the piercing. And I promise, from someone who has had helix piercings done with rings and with straight barbells as well as having one single barbell through my industrial your hair can get caught on them all. If the bar fits properly the balls should fit pretty snugly against your ear.

- Q:I know the ivy sort of glues itself to whatever surface with little sticky pads so that will take care of itself on the back of my house but can I use the existing Ivy for the wisteria to grab onto and climb up or will the wisteria be too heavy and pull the ivy down? I'd rather avoid having to build something for the wisteria to wrap itself around. Any suggestions? Thanks! : )

- No, ivy isn't that strong. One can easily unzip it from the walls. Wisteria is way too heavy for ivy. Plus you have the root competition down below. Ivy creates an incredible dense mat of roots , little grows with it. Wisteria would have quite a battle on its hands for root space and nutrients.

- Q:Latch type disc scaffolding accessories is a national patent product

- Pankou scaffolding is a new scaffold, the products imported from Europe in the last century in 80s, is the product after bowl-scaffold upgrade

- Q:A 520 kg box sits 1.4 m from the left end. What is the tension in the right hand side wire? (g = 9.8 m/s2) ____________ Newtons

- Because the scaffold is not moving, we can assume that the net Torque acting on the scaffold equals zero. Net Torque = 0 torque = Force x distance (d) Use the left end of the scaffold as the center point. This will eliminate the Torque caused by the left wire (d = 0, so torque = 0) There are now three forces creating torque on the scaffold. There is the weight (m x g) of the scaffold, at 3.5m from the left end. m1 x g x 3.5m There is the weight of the crate, located 1.4m from the left end: m2 x g x 1.4m These two torques are countered by the torque caused by the Tension (T) of the right wire, located 7m from the left side. T x 7m The sum of these torques is zero. (T x 7m) - (m1 x g x 3.5m) - (m2 x g x 1.4m) = zero solve for T T = ((m1 x g x 3.5m) + (m2 x g x 1.4m)) / 7m T = ((115kg x 9.8m/s^2 x 3.5m) + (520kg x 9.8m/s^2 x 1.4m)) = 1.58 x 10^3 N Hope this helps.

- Q:Introduction of external scaffolding

- 2 the size and surface quality of steel pipe shall meet the following requirements:1) the new steel pipe should have quality certificate, quality inspection report; steel surface should be flat and smooth, no cracks, scarring, delamination, dislocation, bend, burr, indentation and scratch depth of steel pipe; allowable deviation table item allowable deviation inspection tool 1 welded steel pipe size (mm) diameter 48 wall 3.5 -0.5 thick 2 vernier caliper at two ends of the steel tube shear diagonal deviation 1.7 corner ruler feeler, the outer surface of the steel pipe 3 corrosion depth is less than or equal to 0.50 bar 4 vernier caliper end bend L = 1.5m = 5, 5 pole bending steel ruler 3m<l = 4m4m<l = 6.5m = 12 = 206 level bar, inclined bar bending steel pipe L = 6.5m = 302) from drilling pipe.

- Q:Specific requirements, the civil code is what ah! Thank you very much, I am lack of this kind of information, I hope you can tell me which of the following

- Calculation basisScaffolding input: for the template support part of the steel pipe material in accordance with the 1.5 layer of the amount of consideration: the amount of external scaffolding steel pipe in accordance with the full closed scaffolding consideration; safety net in accordance with the external scaffolding full consideration.

- Q:My mom wouldn't let me get snakebites or cyberbites but she will let me get my scaffold pierced. I know people have different things for pain etc etc I know it will hurt but I want it pierced. So, to someone who has gotten it pierced or knows about it is there anything special you have to do to take care of it or is it just like the ear lobe piercing.

- it probably does hurt cuz of your cartilage just put rubbing alchahol on it and it should be okay =)

- Q:i was thinking of having it done. google it if you don't know what it looks like. but i can't handle pain too well, and as i've seen on youtube, its not nice lmfao, i know pain varies from person to person, but any ideas on how to like take your mind off it? im quite young and this is my first major piercing, i only have my lobes done twice;), and does anyone know a good place to find nice barbells once it's healed:)? thanks:)!aaand do you think this is a nice piece to put in once its healed?

- I okorder for barbells. They have some pretty epic lightnight bolt ones and zigzags and they are like 3 bucks!!!! You can never find them in the mall like that :P lol. Anyway, i deff. think you should get the piercing. It's worth the pain. It'll be over in 2 seconds lol. Good luck :D

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Heavy Duty Prop 3.0M-5.0M Q235 Steel Prop Standard EN1065 CNBM

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 pc

- Supply Capability:

- 30000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords