Heavy Duty Prop 2.2M-4.1M Q235 Steel Prop Standard EN1065 CNBM

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 pc

- Supply Capability:

- 30000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

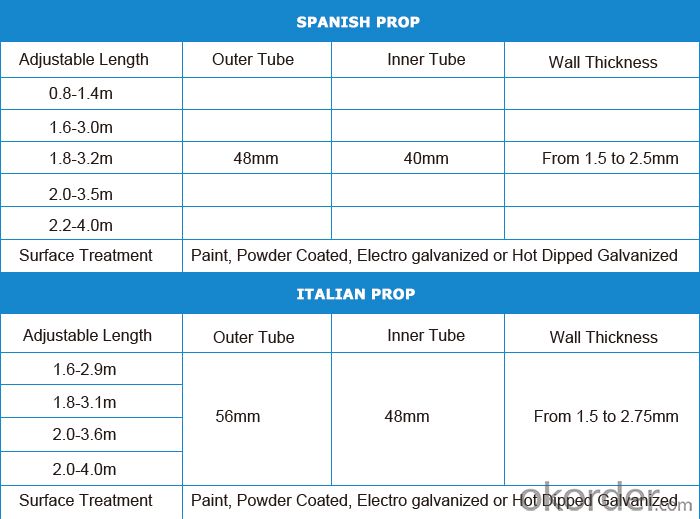

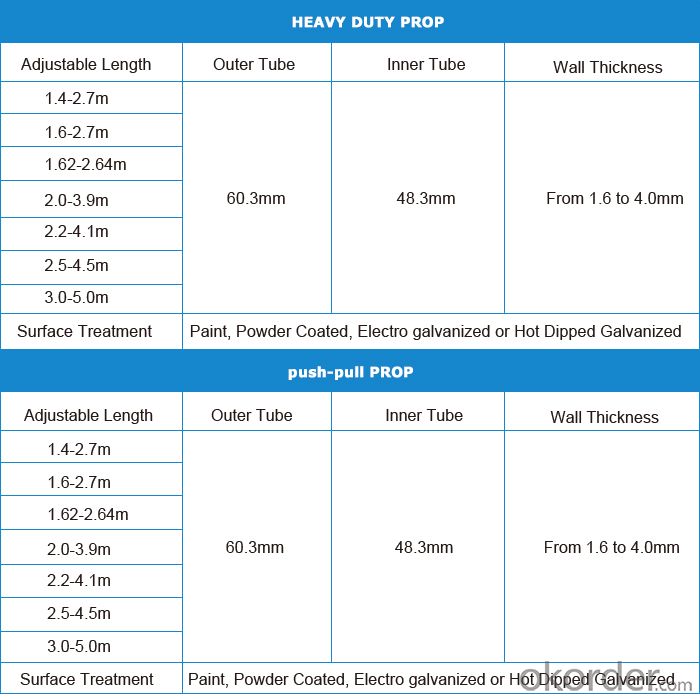

Quick Details of Heavy Duty Prop 2.2M-4.1M Q235 Steel Prop Standard EN1065

Material :Q235 carbon steel

Surface treatment :painted/electro-galvanized/power-coating/hot dipped galvanized

Standard: EN1065

Thickness :1.6mm-3.0mm

Descriptions of Heavy Duty Prop 2.2M-4.1M Q235 Steel Prop Standard EN1065

Our steel prop is a very Economical & practical & simple & easy installation bracing member with very high bearing capacity.

The steel props are very good vertical support suitable for various shaped slab formworks and popularly used in vertical structure support system. 4000 tons annual output.

Our steel prop used as a formwork is with very high bearing capacity.

Steel prop's vertical load capacity (within 4 meters length) can reach 10 KN.

Nuts are strictly manufactured according to national standard and with 10 tons load capacity.

Basic load capacity ≥15KN tested by national authorized organizations.

Shortening working hours & high efficiency

Firm structured props with high strength bearing capacity perfectly resisted the external shocks.

Galvanized prop surface process

Practical & Economical steel props make the buyers feel safe.

FAQ

1. What is considerations of Scaffolding installation?

There must be a fire protection measures and specialist care, safety personnel patrol inspection when electricity, gas welding work on the scaffold,

(1) scaffold frontage hurtful to prevent falling objects protection is required.

(2) During take down the scaffolding, fencing and warning signs should be set up on the ground, prohibit others person besides the operator

2.What are the certifications of your products?

Certified by SGS, BS1139, EN74, Local Test Report.

3. How long is the warranty period for your product?

Our products warranty is 2 years.

- Q:I've wanted an industrial/scaffold piercing for ages! My mum is finally looking into letting me have it done. Any advice about it? How can I hide it for school? What's the healing time? :) thank you for any feed back.

- no its sixteen interior the united kingdom for any variety of ear piercing sixteen with out parent permssion and it will harm rather undesirable take a protracted time to heal and it will value approximately ?35-?40 and clean it with salt water.

- Q:Who has external scaffolding construction program

- See the following table for permissible deviation of steel pipe:Item deviation check tool1 welded steel pipe size (mm) outer diameter 48Wall thickness 3.5-0.5 vernier caliperThe 2 ends of steel tube shear oblique deviation 1.7 feeler, corner rulerThe corrosion of 3 steel tube outer surface depth of less than 0.50 vernier caliper4 kinds of rod end bending L = 1.5m = 5, steel ruler5 pole bending 3m<l = 4m4m<l = 6.5m = 12Less than or equal to 20

- Q:Want to rent the scaffolding in the county, you need to cast how much money

- In addition, there are disc scaffolding and other accessories, so you can estimate how much you need to invest

- Q:HELP me out please. im struggling with this book

- I dont think she explained the rose bush very well. i think that it refers to Good and bad. Good being the rose and bad being the thorns Hester said in the book that she picked Pearl off a rose bush. Hester loves pearl but also fears her

- Q:how long should i leave it before i change it, should i do it myself or go to the piercer to they can do it?and is it still normal for the pericing to hurt after quite a while of having it done?

- Hi :) You can change it after 4 months usually But sometimes it can take up to a year It depends on the person , everybody's body heals differently You should go back to your piercer and ask if it's healed enough to change the jewellery Yep , it's normal A scaffold piercing goes through the cartilage and cartilage piercings can take up to a year to fully heal :)

- Q:hi guys i got my scaffold piercing a couple of days ago and it keeps bleeding on and off and there was dry blood but i removed it and its bleeding more what could i do step by step to keep total care of my piercing to get rid of all these problem please help it will really be appreciated

- leave the dry blood let it heal be patient

- Q:What are the advantages and disadvantages of the fastener type steel pipe scaffold and bowl buckle steel tube scaffold

- (2) efficacy: the most commonly used rod length of 3130MM, weight 17.07KG. The entire frame cannibalize speed is 3 ~ 5 times faster than conventional, faster effort to fight demolition, workers with a hammer to complete all assignments, to avoid the inconvenience caused by bolt operation; (3) with strong: the main components are the ordinary steel tubular scaffolding steel pipe, steel pipe connecting fastener with general availability in general, strong.

- Q:so yeah as it says above^should i just wait till it no longer hurts, or do you have to wait a certain amount of time...

- I wouldn't suggest changing it for at least 6 weeks. You have to allow the skin to heal before touching, turning or changing the bar. If you do change it beforehand, you risk damaging the skin and cartilage surrounding the piercing. I know that I didn't change mine for about 8 weeks, and I haven't ever had a problem with it.

- Q:Also what 2 cell populations in the body that don't routinely undergo cell division

- The first one is vague. The answer could be the mitotic spindle. It might be kinetochore microtubules. It might be talking about the kinetchores on the chromosomes instead of the microtubules that attach to the kinetochores. It could possibly even be talking about the centromeres, though to me that seems less likely. Neurons in the adult brain (and mature muscle cells?) do not routinely undergo cell division.

- Q:In the Scarlet Letter, when Dimmesdale asks Hester who Chillingworth really is, why does she keep her oath to him of not revealing that he is her husband? Guilt? Morals? Thanks

- The rosebush grew to become in front of the darkened, detrimental penal complicated, between many much less suitable flowers. i think of of it symbolized that there is popularity in even the worst of souls. it may serve, enable us to need, to advise some candy ethical blossom, that's found alongside the song, or relieve the darkening of a tale of human frailty and sorrow.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Heavy Duty Prop 2.2M-4.1M Q235 Steel Prop Standard EN1065 CNBM

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 pc

- Supply Capability:

- 30000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords