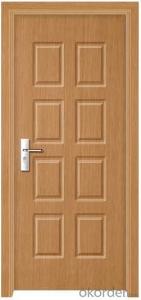

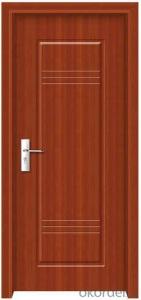

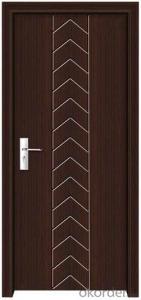

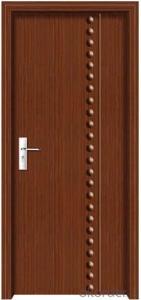

heat trans-printed Security Door Joining together door

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 set

- Supply Capability:

- 20000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

steel security door

1. Suface finish: heat trans-printed

2. Door leaf thickness: 50mm/60mm/70mm/90mm

3. Cold rolled steel sheet:

0.6/0.7/0.8/1.0mm (door leaf)

1.2/1.35/1.8/2.0mm(door frame)

4. Filling material: honeycomb core or fireproof cotton

5. Hinges: 5 galvanized steel hinges

6. Locks: auto lock or machine lock, consisting of additional 13 locking points in doorleaf 7. Threshold: steel or Stainless steel threshold

8. Various designs and colors are available

9. Standard dimension: 2050x960/900/860 x 50mm/60mm/70mm/90mm or customized

10. Accessories: hinges, lockset, handles, viewer, doorbell, rubber seal,etc.

Opening direction: left / right ; outside/inside;

Packing: film & foam and strong carton

Payment Item:T/T,30% deposit in advance,70% against copy of B/L

Deliver Time:20-30days after receiving 30% deposit

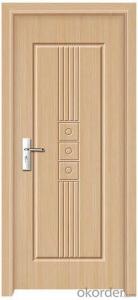

Joining together door

Size:960X2050mm /860x2050mm

door leaf thickness:90/10cm

Surfacing: vacuum transfer

Material of door leaf:1.0mm Galvanized sheet steel

Material of door frame:2.0mm Galvanized sheet steel

Main Lock: connecting ring lock with seven bolts

Lock core: lock core of double curve

Filling: Air Alloy

Handle: luxury gold-plated handle

Hinge: stainless steel hinge with copper chrome

Doorsill: 304 stainless steel doorsill

Seal: high resistance insulation sealing strip

Peephole: 220°copper peephole with wide-angle high definiti

- Q:More than a decade of wood doors and windows stripping, long time no one lived there is a taste how to do

- Recommendation: Equipped with a ventilation device, such as air conditioning, ventilation fans and so on. The easiest way is to open the window. If the window is not convenient, get a blinds.

- Q:My house is old-fashioned house is a wooden door closed with a gap next door people cooking special spicy straight to my family do not know how to solve the sadness of my death

- Where is your neighbor home cooking ah if it is indoors, called neighbors home furnishing chimney, cooking when the door, window closed

- Q:Marriage room with a good wooden door?

- Well ,,, wood door environmental protection, sound insulation effect is good, durable Hong Chang wooden doors, professional original wooden door manufacturers

- Q:Home to do wood processing and doors, and now the university to choose what professional good?

- You can choose the interior design profession, the future development prospects are good

- Q:How to deal with the shrinkage of the original wooden door

- Solution 1 First of all to be clear, shrinkage and cracking is different. Shrinkage is the thermal expansion and contraction of the physical properties of wood, mainly in the door to help the door between the core board, with the Department of the expansion joints caused by the expansion of the door core plate to open the paint exposed white; cracking is due to high moisture content, Poor process caused by, is a quality problem. The natural properties of the logs determine its variability, made after the product, a certain degree of contraction is inevitable, as if the bridge, the road should be left with the same shrinkage, the higher the water content of the greater shrinkage, the general wooden structure Basically can not solve the problem. Wooden door for the characteristics of these logs, the source control and process control to grasp the way to solve: 2 source control: wooden doors on the one hand selection of stable performance of imported timber, the use of raw materials are first through the international advanced steam drying, stereotypes technology, And then the second drying treatment, the wood moisture content control between 8% -12%, and then according to the product used in the classification of the region. General hardwood tree drying cycle should be about 25 days, some drying cycle and even up to 40 days -50 days. 3 process control: by improving the production process, the original anti-shrinkage anti-cracking treatment technology, the first to do after the paint assembly, set the shrinkage joints, with the joints to strengthen the strength of taps and so on, and truly anti-shrink, anti-cracking, Solid wood door contraction cracking problems.

- Q:Wooden doors, solid wood doors, solid wood composite doors, wooden doors, what is the top ten brands?

- Wooden door ten brands: crown cattle, Run Cheng Chuang, Chi Shang, 3D, Choi source emperor,

- Q:Who knows how much the original wooden door of the simple wood

- 2 thousand to several thousand sets ranging from!

- Q:Pearl River piano wood can prevent termites? My house frame has termites, from the piano very close, how do?

- Although the Pearl River piano wood through a strict pest control, but in order to fool or do a good job to do ants it ~!

- Q:How about the quality of the wooden door?

- Quality is good, the price is a bit high, hope can help you

- Q:Why do you want to add money to the original wooden door?

- The original wooden door to do white After the problem went to the big, will crack. And if not open paint, then purely waste material ~ ~ ~ ~, but the open paint to do the basic wood are the original lines, and many are not rules, anyway, how high the process requirements ~~~~~~~

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

heat trans-printed Security Door Joining together door

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 set

- Supply Capability:

- 20000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords