Heat-resistant Silicone Rubber Seal Strip

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 kg

- Supply Capability:

- 100000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Heat-resistant Silicone Rubber Seal Strip:

1. Brief Description of Heat-resistant Silicone Rubber Seal Strip

We can customize any kinds of rubber products,such as extruded rubber tube, profiles; molded rubber o ring, gaskets; rubber sheets ,cold shrink cable accessories any other shape of rubber products.

2. Main Features of Heat-resistant Silicone Rubber Seal Strip

1. Ambient temperature from under 50 degree to 300 degree.

2. with backed tape, easy to install

3. High Impact Resistance, good process ability shockproof, soundproof, heatproof, insulation.

4. Different color and shape can be made according to your drawing

5. Transparent, smooth, Soft and flexible. Non-toxic tasteless

6. Function: windows, doors

7. High strength, flame resistant

8. Good elasticity

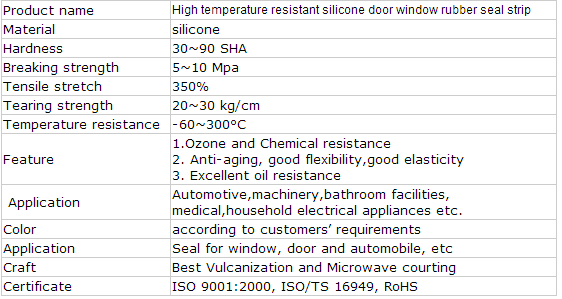

3. Main Specification of Heat-resistant Silicone Rubber Seal Strip

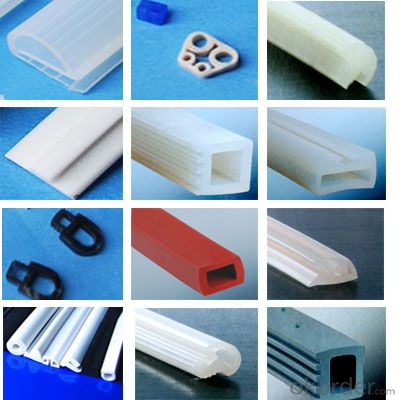

4. Pictures of Heat-resistant Silicone Rubber Seal Strip

5. FAQ

1.Q:Are you a factory or trading company?

A:We are a factory.

2.Q:Can you ensure your quality?

A:Yes,our products have past ISO certificate.We have specialized technical department and

QC team,we will strictly check the material.color,size,performance of the sample step by

step.And every item will be checked before packing.

3.Q:Can you delivery the products on time?

A:Our factory have a production capacity of 400T/month.We will calculate the special delivery

time for you,and ensure the arranged delivery time.

4.Q:Why I choose your products?

A:We can produce the products strictly as your request,and our price is according to the

product material cost,technology cost,labor cost,and other necessary cost.Our price will be

reasonable.

5.Q:Can I get some samples?

A:We offer free sample.

6.Q:Can I visit your factory?

A:Yes, welcome to visit our factory.

- Q:Explain why butyl rubber is more resistant to oxidation and aging than other elastomers, such as natural rubber

- Ding Ji rubber (abbreviation: IIR English Name: Isobutylene-isoprene Rubber)Ding Ji rubber is an elastomer made from a small amount of isoprene (butadiene) copolymerized with isobutene with a high degree of saturation. Generally do not need refined refining, pay attention not toBlends with unsaturated rubber with low degree of unsaturation. Use super accelerators and less sulfur or cure with resin. Due to the slow vulcanization rate of ordinary butyl rubber and high unsaturated rubberIts poor compatibility, self adhesion and co adhesion were not good, and then it was modified by halogenation, which improved its curing rate and compatibility with other high unsaturated rubber

- Q:What is the composition of the vulcanizing agent for silica gel?

- Vulcanizing agent is organic peroxide, or bridging agent, used for curing silicone rubber (Xi Likang), EVA and curing of unsaturated polyester.

- Q:Why do rubber products become so long that they seem to melt and become sticky on the surface?

- Rubber is a word now often refers to natural rubber, it can be said that not all products are easy to sticky rubber. Natural rubber tends to stick because it contains many carbon carbon double bonds and is prone to oxidation.

- Q:Is rubber flame retardant?

- Rubber itself is flammable, in the production process can be filled with some flame retardant material, it can reduce its flammability, but at the same time reduce its inherent good performance, such as abrasion resistance, elasticity, etc..

- Q:Why is natural rubber a strategic material?

- Rubber is an important strategic material, in the national defence application is very extensive, for example, a tank with more than 800 kg of general rubber; thirty thousand ton warship with sixty-eight tons of rubber, military equipment, air force facilities, almost all defense engineering rubber footprint. The use of rubber made ship, tent, warehouse and protective equipment, clothing etc. there are many varieties of bath water. As for the anti - tip technology needs high temperature, low temperature, oil resistance, high vacuum resistance and other special properties of the rubber, the constitution of 0 products is indispensable. With the development of national defense modernization, rubber, which is capable of resisting the temperature range of minus 100-400 DEG C and capable of resisting various acids, bases and oxidants with special properties, is being developed and manufactured.

- Q:How is rubber made? What kind of equipment do you need? How much is it?

- The processing process of rubber is mainly to solve the process of plastic and elastic contradictions, through various means of processing, the elastic rubber has become the plastic rubber, adding various in the preparation of semi-finished products, and then through the vulcanization is has semi-finished plastic and rubber products into high elasticity and good mechanical performance the.

- Q:How to improve the hardness of rubber?

- Increasing the degree of crosslinking (increasing the dosage of vulcanizing agent and prolonging the curing time properly);Increase the dosage of reinforcing agent, or choose reinforcing agent with high structure and large specific surface area;Hardening resin, high styrene and other hardening agent;

- Q:Does the fuel pipe for automobiles belong to rubber products?

- If it is a diesel car, then the high pressure part of the metal pipe only, in the low pressure part of the rubber tube.

- Q:What is the relationship between synthetic rubber and crude oil?

- Synthetic rubber material also has excellent heat resistance, cold resistance, corrosion resistance, and little affected by environmental factors, synthetic rubber materials and suitable for 60 to 250 degrees below zero normal use.

- Q:Does anyone know how to deal with the frosting of rubber and how to prevent it?

- To reduce blooming, mainly by adjusting the formula to achieve, such as reducing the amount of antioxidant in summer, storage time is short before vulcanization, if you can consider the use of paraffin wax, microcrystalline wax, if sulfur spray frost can consider changing into insoluble sulfur. Because I don't know your recipe, I adjust it according to the actual situation.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Heat-resistant Silicone Rubber Seal Strip

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 kg

- Supply Capability:

- 100000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords