Heat Resistant Aluminium Foil Laminated Fiberglass Fabric

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description:The combination of laminating an aluminum metallic/film heat shield to a layer of protective fiberglass insulation protects personnel or equipment by reflecting radiant heat. The fabric have advantages of smooth and flat surface, high resistant, good tensile strength, airtight, watertight, good sealed performance, strong weather-ability, etc.

Features: High Reflectivity, Waterproof, Fire Resistant, Heat Resistant

Application: Thermal Insulation Jackets, Cover, Blanket, Mattress, Pad,Heat Shields, Thermal Barrier, Industrial Safety Apparel

PRICE: USD3.2 per square meter

UNIT: square meter

MOQ: 500 square meters

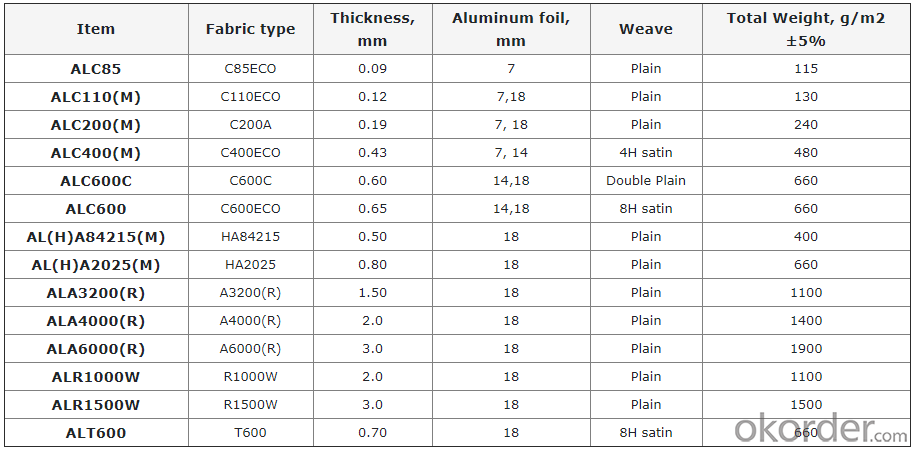

Weight: 220gsm-1200gsm or customized

Width: 1m-2m or customized

Yarn Type: E-glass

Standing temperature:550℃

Product name: Aluminium Foil laminated fiberglass fabric

Coating/Finish/Surface Treatment: Aluminium Foil laminated

Roll length: 50 meter or customized

Color: silver grey

Weave Type: twill woven

Alkali content: alkali free

Processing service: cutting

Material: fiberglass fabric, Aluminium foil

Thickness: 0.2mm to 1.7mm or customized

Size: can be customized

Supply ability: 300000 meters per month

Packaging: Aluminium foil laminated fiberglass fabric rolls packed in cartons loaded on pallets or according to customers' requirements.

Lead time: 7-30 days

- Q:What are the cracks between the brick wall and the beam column, the cracks between the planks and the cracks in the plasterboard?

- Crack plate, gypsum board, kraft adhesive bandage or Dacron patch, then putty, paint do.

- Q:Are fiberglass fabrics suitable for use in the mining industry?

- The mining industry finds fiberglass fabrics to be a suitable choice. These fabrics are renowned for their exceptional strength and durability, making them an ideal option for demanding tasks like mining. They exhibit impressive resistance against chemicals, abrasion, and high temperatures, which are prevalent in mining operations. Moreover, fiberglass fabrics offer the advantage of being lightweight, facilitating their handling and installation in mining equipment and structures. Their low thermal conductivity also aids in reducing heat transfer within mining environments, safeguarding workers and equipment from excessive heat. Additionally, fiberglass fabrics possess excellent electrical insulation properties, a crucial aspect in mining operations where electrical hazards pose a risk. Furthermore, they are non-combustible, contributing to enhanced safety in potentially hazardous mining environments. Furthermore, fiberglass fabrics can be produced in various forms, including woven, non-woven, and composite materials with other fibers or resins. This versatility permits customization to meet specific requirements of the mining industry, such as flame resistance, chemical resistance, or increased strength. In conclusion, fiberglass fabrics are highly suitable for the mining industry due to their strength, durability, resistance to chemicals and high temperatures, lightweight nature, electrical insulation properties, and customization options. They offer a reliable and safe solution for diverse mining applications, ensuring the efficiency and safety of mining operations.

- Q:Can fiberglass fabric be used for car covers?

- Yes, fiberglass fabric can be used for car covers. Fiberglass fabric is known for its durability and resistance to tearing, making it a suitable material for protecting cars from various external elements such as dust, dirt, and UV rays. It is also lightweight, easy to handle, and can be easily customized to fit different car sizes and shapes. Additionally, fiberglass fabric has excellent heat insulation properties, which can help protect the car's interior from extreme temperatures. However, it is important to note that fiberglass fabric on its own may not be waterproof, so it is recommended to use a waterproof coating or layer underneath the fabric for added protection against rain and moisture.

- Q:Are fiberglass fabrics suitable for use in the renewable energy sector?

- Yes, fiberglass fabrics are suitable for use in the renewable energy sector. They possess excellent thermal and electrical insulation properties, making them ideal for applications such as wind turbine blades, solar panel components, and insulation for renewable energy infrastructure. Additionally, fiberglass fabrics are durable, lightweight, and resistant to environmental factors, making them a practical choice for various renewable energy projects.

- Q:Can fiberglass fabrics be used in high-temperature environments?

- Indeed, high-temperature environments can accommodate the utilization of fiberglass fabrics. The exceptional resistance to heat possessed by fiberglass renders it an optimal option for purposes necessitating insulation or safeguarding against elevated temperatures. Its structural integrity and performance remain intact even when confronted with temperatures as high as 1000°F (538°C). Industries such as aerospace, automotive, and manufacturing frequently employ these fabrics due to the prevalence of high temperatures in their operations. Moreover, fiberglass fabrics exhibit characteristics of being lightweight, durable, and possessing commendable thermal conductivity, thereby establishing themselves as an ideal material for high-temperature surroundings.

- Q:Is fiberglass fabric resistant to chemicals in chemical processing plants?

- Yes, fiberglass fabric is generally resistant to chemicals in chemical processing plants. Fiberglass is known for its excellent chemical resistance properties and is widely used in various industrial applications, including chemical processing plants. It is highly resistant to a wide range of chemicals, including acids, alkalis, solvents, and many other corrosive substances found in chemical plants. This resistance makes fiberglass fabric a reliable and durable material for use in the construction of equipment, piping, tanks, and other components in chemical processing plants. However, it is important to note that the specific type and concentration of chemicals being handled should be considered when selecting the appropriate fiberglass fabric to ensure optimal chemical resistance.

- Q:How is fiberglass fabric used in the production of thermal gloves?

- Fiberglass fabric is used in the production of thermal gloves to provide insulation and heat retention properties. It is often used as a lining material or incorporated into the glove's construction to trap and retain body heat, keeping the hands warm in cold environments. The fiberglass fabric's thermal resistance helps to minimize heat loss and create a barrier against cold temperatures, making it an essential component in manufacturing high-quality thermal gloves.

- Q:How is fiberglass fabric bonded to other materials?

- Fiberglass fabric can be bonded to other materials using various methods and adhesives. One common technique is using epoxy resin, which provides a strong and durable bond. The process involves applying a layer of epoxy resin onto the surface of the material to be bonded, then placing the fiberglass fabric on top of the resin. Pressure is then applied to ensure proper adhesion and to eliminate any air bubbles. The epoxy resin is left to cure, usually for several hours or overnight, creating a strong bond between the fiberglass fabric and the material. Another method is using adhesive films or tapes specifically formulated for bonding fiberglass fabric. These adhesive films are often heat-activated, meaning they require the application of heat to achieve proper bonding. The process typically involves placing the adhesive film between the fiberglass fabric and the material to be bonded, then applying heat using a heat gun or other suitable equipment. As the adhesive film melts, it creates a bond between the fiberglass fabric and the material. In some cases, mechanical fasteners such as screws, rivets, or staples may be used to secure the fiberglass fabric to other materials. This method is often employed when a temporary or removable bond is desired, or when additional strength and stability are required. It is important to note that the specific bonding method used may depend on the intended application and the materials involved. Consulting with a professional or following manufacturer's guidelines is recommended to ensure proper bonding and optimal results.

- Q:How is fiberglass fabric used in the production of boat hulls?

- Due to its exceptional strength, durability, and lightweight nature, fiberglass fabric finds extensive use in the production of boat hulls. This versatile material is created by weaving together fine strands of glass into a fabric, which is then impregnated with a resin, typically polyester or epoxy, to form a solid and rigid composite structure. When it comes to boat hull production, fiberglass fabric serves as a reinforcement material. It is commonly applied in multiple layers, known as laminate, to construct a robust and inflexible hull. The fabric is initially laid down on a mold or frame, taking the desired shape of the boat. Then, the resin is applied over the fabric, fully saturating it and creating a bond between the layers. Once the resin cures and hardens, the fiberglass fabric becomes an integral component of the boat hull. It provides structural integrity, rendering the hull resistant to impacts, flexing, and water damage. The strength of the fiberglass fabric ensures that the hull can withstand the stresses and forces encountered during boating, such as waves, wind, and collisions. Additionally, fiberglass fabric exhibits excellent resistance to corrosion, rot, and degradation caused by exposure to water, making it an ideal choice for boat hulls. It is also relatively easy to shape and mold, enabling boat manufacturers to create hulls of various designs and sizes. Furthermore, if the hull sustains any cracks or punctures, fiberglass fabric can be easily repaired. Simply applying a new layer of fiberglass fabric and resin over the damaged area ensures that the boat remains structurally sound and watertight. In conclusion, fiberglass fabric plays a crucial role in boat hull production by providing strength, durability, and resistance to water damage. Its versatility and ease of repair make it a preferred choice for boat manufacturers worldwide.

- Q:How does fiberglass fabric handle repeated flexing and stretching?

- Fiberglass fabric is known for its exceptional durability and ability to withstand repeated flexing and stretching. Due to its inherent flexibility and high tensile strength, fiberglass fabric can handle these mechanical stresses without significant damage or loss of performance. The interwoven fiberglass strands provide the fabric with excellent resistance to compression, bending, and stretching, making it highly suitable for applications that require repetitive motion or dynamic loads. Additionally, the unique properties of fiberglass, such as its low coefficient of thermal expansion and high resistance to chemicals and moisture, further contribute to its ability to handle repeated flexing and stretching. Overall, fiberglass fabric is a reliable and robust material that can withstand the demands of various industries and applications.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Heat Resistant Aluminium Foil Laminated Fiberglass Fabric

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords