HDPE/PP/PVC Vertical Type Double Wall Corrugated Pipe and PVC Ribbed Pipe Extrusion Line

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 30 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery

| Packaging Detail: | wooden case, or customized |

| Delivery Detail: | 35 days after deposit received |

Specifications

1. good quality and good material

2. easy operation and labor saving

3. high output and high reputation

Properties: DWC pipe is mainly used for water drainage system. It is a fully computer controlled line. It features high and stable output capacity, and highly automatic operation. For HDPE, you can choose high efficient single screw extruder. For PVC, you can choose conical twin-screw extruder or parallel twin- screw extruder. Forming system consists mould and corrugator. Mould blocks can be easily changed and they have air or water cooling system. The belling process is on line. High precision cutting can be guaranteed by cutting machine. The production line can also be equipped with SIEMENS PLC system.

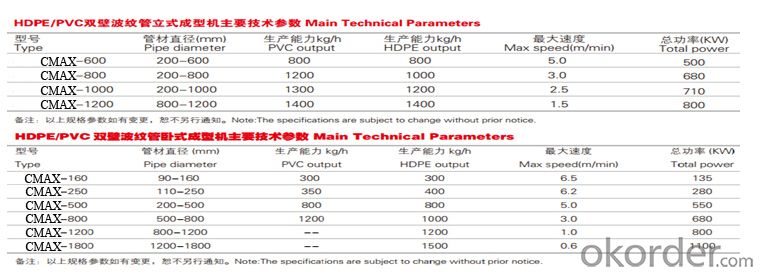

Technical parameters:

Features of Production line

1. It adopts special screw and barrel,ensuring plasticizing quality and high transparency

2.Special designed extrusion die head has layer control,each layer thickness can be adjusted freely

Pictures of PVC Plastic Steel Spiral Pipe Equipment

For more information, you may contact with me directly, and i would give satisfying help.

Packaging & Shipping

This machine would be packed with steel frame and plywood panels.

It is easyier to get through customs inspection.

User manul would be printed out, and be put in the shipping box with machine. And PDF copy would be sent to you for more convenience.

Our Services

OEM service offered.

Engineers available for overseas customer, for machine trial and teaching.

Suggest related material and mold for you, tury-key business to save your time.

- Q:Who knows the temperature regulation method of the extruder?Any information will do

- Extrusion molding in plastic processing is called extrusion, using hydraulic pressure in rubber extruder processing in extrusion die extrusion. That itself means that the material through the extruder barrel and screw the function between the side heating plasticization, screw edge is pushed forward, a processing method of continuous head made by various sections of finished or semi-finished products.In the fiber chemical industry is also useful in the extruder to the spinneret for melt spinning. The material, process of extrusion used in thermoplastic plastics and rubber, for batching, granulation, rubber filtration, continuous production, manufacturing various continuous products such as pipe, profile, sheet (or sheets), thin film wire and cable coating, rubber tire, tube noodles barrel, a sealing strip, the production efficiency is high. In the production of synthetic resin, can be used as reactor extruder, continuous polymerization and processing, in rubber industry, the compression ratio of different extruding machine can be used to unmasticated natural rubber of different materials. Compression extrusion machine than some different. [edit this paragraph] the principle of extrusion molding material since the bucket into the barrel, the screw rotates under the action of the cylinder wall and the surface of the screw friction shearing forward delivery to the feeding section in the loose. Forward transport also is compacted; the compression section, screw groove depth, further compaction, while the barrel heating and screw and cylinder wall friction shear, the material temperature rise began to melt, the compression section ends; homogeneous section material uniform, constant temperature, fixed quantity, squeeze out to melt. After a head forming, by setting the product.

- Q:Extrusion machine operating procedures, specific points, thank you!

- 1, operators must be familiar with the procedures, the safety test qualified, wear good protective equipment, shall operate the equipment.2 when the power is on, check whether the thermal control of the electric appliance is sensitive and reliable, whether the thermocouple indicates the temperature is correct or not, and if there is a problem, please repair the personnel to exclude them.3 when driving, should check the main reducer, traction non polar transmission, the line is stepless gear box lubrication is normal, fan ventilation is good.4 before driving, pay attention to the heating temperature of each section, whether the actual temperature required by the process, the heat preservation time should be enough, and the initial heating time can not be less than 3 hours heat preservation.5, not in the plastic bad, scorched, aging, extrusion production, in case of accidents, and found the above problems, immediately try to rule out.

- Q:Who knows the structure of the big extrusion machine head (has cooled), smash what structure, model of plastic crusher?

- There is a kind of broken engineering material. I wonder if you can find it

- Q:What are the two types of extrusion?

- Extrusion? The extruder. The extruder is divided into single screw extruder and twin screw extruder, and the twin screw extruder is divided into two parts: flat, double and cone.

- Q:Extruder price

- According to the size of the screw, single and double screw configuration is different, there are many different prices between fifty thousand to two hundred thousand, we specialize in the production of extruders, crushers and mixing machines, high quality and low price, contact information on the user name

- Q:Taper twin screw extrusion machining of plastic masterbatch? What ancillary equipment do you need?

- Can, but need feeding machine and related auxiliary mixing granulator, the cost is not low, but the effect is less than double make flat,

- Q:What is the principle of the 45 extruder machine?

- The principle of the extruder is the theoretical process of heating, melting and mixing in the process of plastic conveying, including solid conveying principle, melt transportation principle, mixing principle, and solid bed crushing process, etc..

- Q:PVC extrusion machine extrusion stone floor no pressure, what reason?

- PvC stone floor extruder pressure is adjusted by the screw and die head

- Q:Comparison of injection molding machines and Extruders

- The plastic to replace steel or nonferrous metal, plastic cement, which is widely used in agriculture, building materials, packaging, machinery, electronics, automobiles, household appliances, petrochemical and defense, extruder and daily life other fields. So it can be predicted that in twenty-first Century, the plastic will be one of the most important raw material of human activities. The extruder design due to extrusion molding is the main form of plastic processing, so the development of plastic extrusion molding technology and equipment has important significance. The polymer materials used in blending type mixing equipment modification there are three main types: parallelwith twin-screw extruder, reciprocating screw kneader and series disc extruder. The small corotating twin screw extruder has domestic production can squeeze But tons of large mixing extrusion granulation unit will rely on the import machine technology. At the same time. Reciprocating screw kneader and series disc extruder is a necessary device for preparing high fill and high added value of polymer alloy, the current domestic research on them is just in the prototype stage, specifications, varieties not all, have broad prospects for development.

- Q:What impact does the extruder vacuum pump open or close on the extrusion product?

- If the vacuum pump is opened, the air in the extruded product will be removed and the product material will be more closely packed.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

HDPE/PP/PVC Vertical Type Double Wall Corrugated Pipe and PVC Ribbed Pipe Extrusion Line

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 30 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products