HDPE Pipe for Agriculture Irrigation System

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1200 m²

- Supply Capability:

- 1999999 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

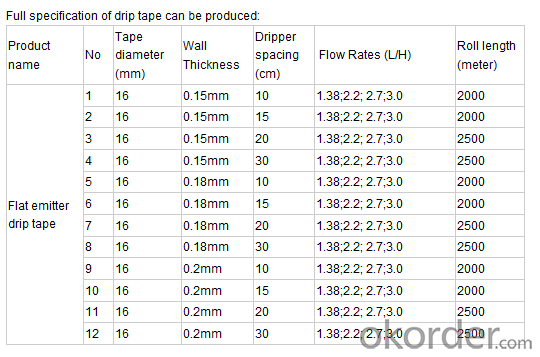

The Application of Irrigation Tape distance 30cm Good Quality:

HDPE Pipe for Agriculture Irrigation System

The layflat hose has a wealth of residential and commercial applications, and it is usually used for general water transfer purposes as well as for submain.Generally layflat hoses are used in the industry of agriculture,in pipe lining and rehabilitation,in removing waste water,in mine dewatering ,in the chemical industry and even for household chores

HDPE Pipe for Agriculture Irrigation System

Features OF HDPE pipe for agriculture irrigation system

1. Seamless drip tape with drippers permanently fixed inside. Seamless construction improves ability to withstand pressure fluctuations.

2. With two parallel blue line helps to ensure upright positioning of the dripper.

3. Manufactured from special grade, virgin polymer ensuring close dimensional tolerance and higher strength even at lower wall thickness.

4. Manufactured with the most modern, state-of-the-art equipment. It’s computerized continuous online quality control ensures reliable quality and consistent performance.

5. Hydraulically designed turbulent flow path emitter with wide cross sectional area and precision inlet filter that makes it a truly clog resistant drip tape.

6. Precision laser drilled outlet holes.

7. Extremely low manufacturing coefficient of variation, CVm ensures high field emission uniformity.

HDPE Pipe for Agriculture Irrigation System

The decription of HDPE pipe for agriculture irrigation system:

Two layers of PVC bonded together encapsulating high tensile polyester fibers.

Thick wall dimensions and strong yarn structure help products to hold connections and resist bursting.

It assumes the conventional round appearance when pressure is being passed through it and then returns to its flat shape after use.It does not need drying and can be rolled immediately after use.

HDPE Pipe for Agriculture Irrigation System

Features of HDPE pipe for agriculture irrigation system:

1.Great durability mainly given by the reinforcement and high-density PVC material.

2.The layflat hoses can have up to 12 inches diameter based on their applications.

3.Extra thickness are added in order to prevent bursting due to pressure in heavy industry.

4.Can be easily rolled up,stored and reused,as it has a very durable construction.

5.The hoses come with a variety of fittings and accessories ensures the water transfer process free of leaking.

6.Temperature range:-5°C~65°C(23~149F)

HDPE Pipe for Agriculture Irrigation System

FAQ Irrigation Tape distance 30cm Good Quality

1.Q:Are you manufactory or trade company?

A:We are the Manufactory specialized in drip irrigation more than 20 years; Our factory have passed IS09000.

2.Q:How can I get the samples?

A:If you need some samples to test, we can make as per your request .You should pay for the transportation freight of samples and our samples cost, while the samples cost can be refundable after you place the order if the amount meets our requirement.

3.Q:How much the transportation freight of samples?

A:The freight depends on the weight and packing size and your area.

4.Q:How long can I expect to get the sample?

A:The samples will be ready for delivery within one week. The samples will be sent via express and arrive in 7-10 days.

5.Q:Can we have our Logo or company name to be printed on your products or package?

A:Sure.Your Logo can be put on your products by Hot Stamping,Printing,Embossing,UV Coating,Silk-screen Printing or Sticker

- Q:My mom always complained to me that whenever I cooked things in plastic bowls or had plastic in the microwave that it was bad for me. Is this myth true??

- www.okorder /

- Q:Can ground cover be used to create a colorful landscape?

- Yes, ground cover can be used to create a colorful landscape. There are many varieties of ground cover plants available that offer vibrant foliage and flowers, adding color and texture to the landscape. Additionally, ground cover plants can be combined strategically to create beautiful patterns and designs, further enhancing the overall visual appeal of the garden or outdoor space.

- Q:Are nursery trays suitable for hanging plants?

- No, nursery trays are not suitable for hanging plants as they are designed for a different purpose. Hanging plants require specialized containers with proper drainage and support for their growth.

- Q:is this ok , plastic bin is cheaper than fish tank

- A lot of breeders use plastic bins for breeding tanks including myself. Plastic is more porous than glass but as long as you don't put chemicals or soap in it it can't absorb it. I keep a lot of my males in one gallon pickle and olive jars. Some are glass and some are plastic. I've kept them in these off and on for 40 years.

- Q:Do nursery trays come with a water level indicator?

- No, nursery trays typically do not come with a water level indicator.

- Q:How do you control weeds in ground cover areas?

- There are several effective ways to control weeds in ground cover areas. Firstly, regular maintenance such as hand-pulling or hoeing weeds can help keep them in check. Mulching with organic materials like wood chips or straw can also suppress weed growth by preventing sunlight from reaching the soil. Additionally, applying pre-emergent herbicides before weed seeds germinate and post-emergent herbicides to actively growing weeds can provide effective control. It's important to choose herbicides that are specifically labeled for use in ground cover areas and follow the instructions carefully.

- Q:What are some ground cover options for slopes and hillsides?

- Some ground cover options for slopes and hillsides include creeping phlox, creeping thyme, English ivy, juniper, sedum, and vinca minor. These plants have spreading growth habits and can help stabilize the soil, prevent erosion, and provide attractive coverage.

- Q:Are agricultural plastic products used in organic composting?

- No, agricultural plastic products are not used in organic composting. Organic composting strictly relies on natural and biodegradable materials to create nutrient-rich compost.

- Q:Can ground cover be used to create a noise barrier?

- Yes, ground cover can be used to create a noise barrier. Ground cover plants, such as dense shrubs or low-growing trees, can help absorb and block sound waves, thereby reducing noise pollution. Additionally, the use of a combination of different plant species with varying heights and foliage can further enhance the noise reduction effect.

- Q:To get into a plastic surgery course after finishing general medicine , do i have to take general surgery after usmle's and then take plastic surgery as a super specialty or after usmle's directly into plastic surgery ?? appreciate your help, thanks :)

- not really as plastic surgery is very specific. you do need to be a doctor first but you go straight to plastic surgery for about 2-3 years education then residency for about 3-5 years. you go straight to plastic surgery. though I prefer neurosurgery and cardiothoraic.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

HDPE Pipe for Agriculture Irrigation System

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1200 m²

- Supply Capability:

- 1999999 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords