HDPE Olive Garden Harvest Net Olive Tree Harvest

- Loading Port:

- Wenzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

HDPE Olive Garden Harvest Net Olive Tree Harvest

Production Description:

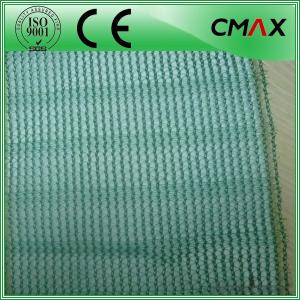

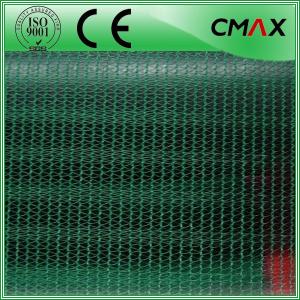

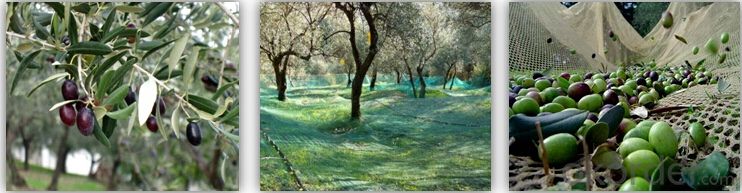

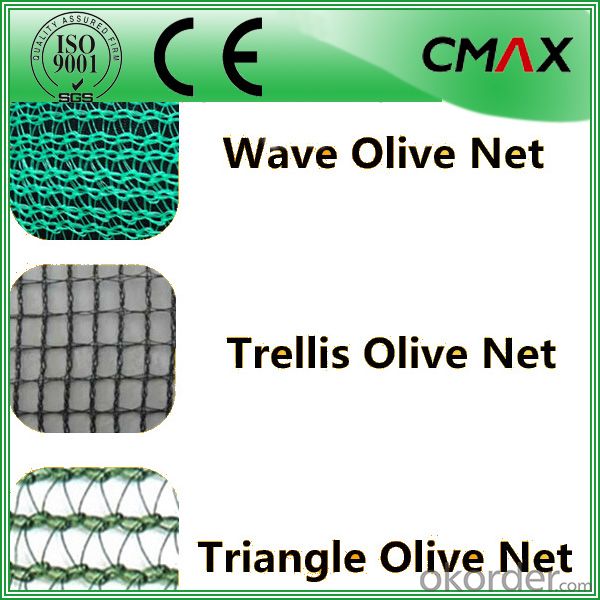

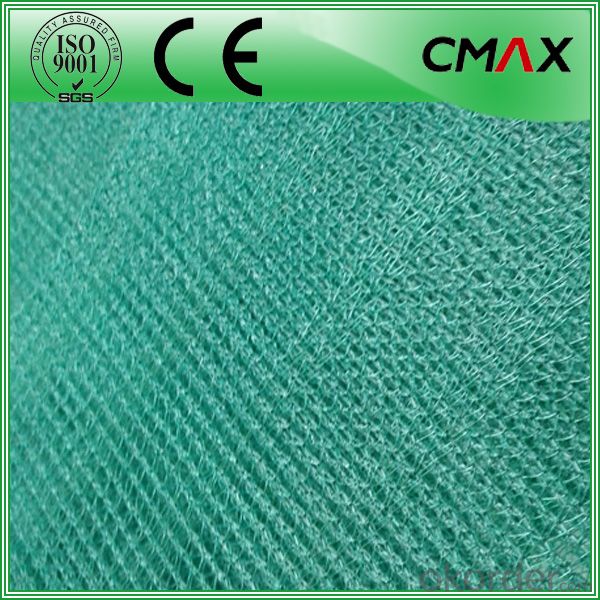

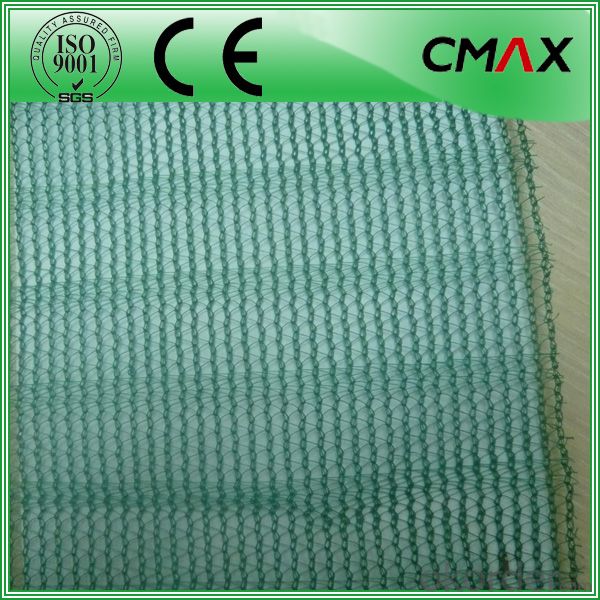

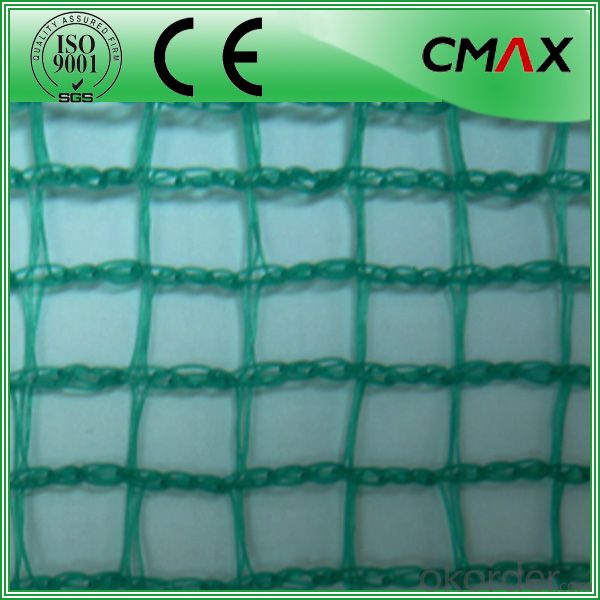

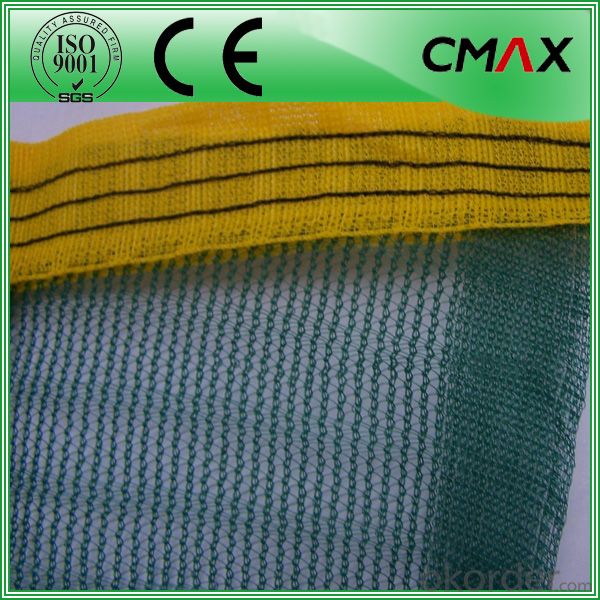

These nets are entirely made of UV stabilised polyethylene monofilament. The nets available have various kind of meshes in order to optimise the different harvesting methods of olives and fruits. Every net is suitable for a different application such as natural falling harvesting, hand harvesting or mechanised harvesting. The nets are available in different weights and colours and can be supplied in rolls or in sheets already stitched together with or without central vent.Olive collection net are used not only for the olive harvest, but also to gather chestnuts, nuts and deciduous fruits in general.

Produced with HDPE virgin material

UV stabilized - Long life

For Food : non-toxic, responsive to current European legislation on packaging for food.

Guarantee 5 years

Green&Black 50g/m2

Farmer used the net to gain olive from tree.

Specification:

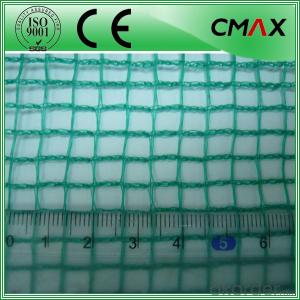

| Type | CMAX-Olive Net |

| Weight | 33-200 gsm |

| Color | Black, Green, Dark Green, etc |

| Width,Length | 1-6m, 50m,100m as your requirements |

| Raw material | 100% Virgin HDPE with U.V Stabilized and irganox |

| Using life | At least 4 years |

| Delivery time | 30 days after deposit |

| Specification | construction(/inch) Warp=3, Weft=4.5, Br.Str.(kg) ,Warp=10, Weft=2 ,Screening factor(%) :10% |

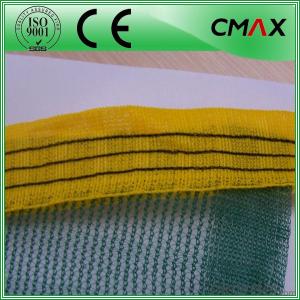

| Packing | rolls with PVC suare tube(5×5cm)/double folded/PE Stretch film/label |

| OEM | If you have your own packing design,we can quickly meet your requirments. |

Application:

Process:

Shipping&Packing:

Delivery Time: 20 Working Days After Confirmed P.O.

Packaging: Each piece packed in plastic bag, and several pieces per bale with PP woven bag outside, or in rolls with inner paper tube with plastic bag outside.

FAQ:

1.Q:Where is your factory located? How can I visit there?

A:Our factory is located in Shanghai, China. You can take flight to Shanghai Hongqiao airport, and 25 mins reach to our factory.

2.Q:What is the material of your products?

A: We use the raw material of High Density Polyethylene (HDPE) with UV Stabilized & Igranox to make our netting

3.Q:How does your factory do regarding quality control?

A: we are very proud to let you know that , We use the best raw material , have at least 5years experienced workers,

the advanced machine and specialized team to assure the quality

We perform Quality Control inspections on 100% of our products.

Our inspection standards are strictly in accordance with the ISO9001 certification system.

- Q:How do agricultural plastic products help with plant disease prevention?

- Agricultural plastic products help with plant disease prevention by creating a physical barrier between the plants and the external environment. This barrier helps to prevent the transmission of diseases by blocking the entry of pathogens, insects, and other harmful elements. Additionally, some agricultural plastic products, like mulch films, can help maintain optimal soil moisture levels and temperature, which further aids in disease prevention and promotes plant health.

- Q:Are nursery trays suitable for hydroponic gardening?

- Yes, nursery trays can be suitable for hydroponic gardening. These trays can provide a convenient and cost-effective way to grow plants hydroponically, as they are designed to hold and drain water effectively. However, it is important to ensure that the trays are made from food-safe materials and have proper drainage holes to avoid waterlogging. Additionally, the size and depth of the trays should be considered based on the specific plants being grown.

- Q:How does ground cover affect the growth of nearby shrubs?

- Ground cover can have both positive and negative effects on the growth of nearby shrubs. On one hand, ground cover can provide protection to the soil, reducing erosion and retaining moisture, which can promote healthy root development and overall growth of the shrubs. Additionally, certain ground covers, like nitrogen-fixing plants, can improve soil fertility and benefit the nearby shrubs. On the other hand, dense and aggressive ground covers can compete with shrubs for resources such as water, nutrients, and sunlight, potentially hindering their growth. Therefore, the type and density of ground cover play a crucial role in determining its impact on the growth of nearby shrubs.

- Q:Can ground cover plants be used to improve soil fertility in a garden?

- Yes, ground cover plants can be used to improve soil fertility in a garden. These plants help to prevent soil erosion, retain moisture, and suppress weed growth, which can all contribute to healthier and more fertile soil. Additionally, some ground cover plants have the ability to fix nitrogen, which can enrich the soil with this essential nutrient.

- Q:How do you prune and trim ground cover plants?

- Pruning and trimming ground cover plants involves removing any dead or diseased branches, as well as cutting back overgrown or straggly growth. The best approach is to use sharp, clean pruning shears or hedge trimmers to make precise cuts. It's important to ensure that at least one-third of the plant remains after pruning to maintain its health and vigor. Regularly monitoring and trimming ground cover plants will help promote dense growth and keep them looking neat and well-maintained.

- Q:I'm making rings out of plastic buttons my craft glue has run out. I was wondering if super glue will reck the plastic buttons? thanks for the help

- No, instant glues (Super Glue, Krazy Glue, etc) won't dissolve plastic... we use it with polymer clay all the time which is also a plastic. The only things to stay away from with plastics are things that contain petroleum-based solvents (the ones that clean up with paint thinner, mineral spirits, etc.) like enamel paints, certain kinds of finishes, etc. Instant glues do best (even those that have been thickened) with *enough* surface areas that match *exactly* and which won't be subject to shear forces (pressure from the side) rather than pulling apart forces. So in order of best adhesion, I'd probably go with: ...2-part epoxy glue ...a strong white glue or one made for attaching to metal (Beacon's GemTac or Jewel It, or Weldbond or The Ultimate by Crafter's Pick)... but not a weaker white glue ...E6000 (for those last two, you may want to sand the surfaces first) (Polyurethane glues like Gorilla Glue will hold anything to anything, but Gorilla Glue is yellow and it swells while curing--so must be weighted or clamped. If you use it, don't start with too much and keep wiping away the part that oozes out in the beginning.) All that depends on the amount of stress your bond would be subjected to though, and less stress could do fine with other glues including clear cements though those aren't flexible at all. HTH, Diane B.

- Q:does anyone out there that has patterns for plastic canvas we can swap and trade

- I have at least 27 plastic canvas patterns books that I was selling at a stuff sale if you are interested. Many from Needlecraft Shop, Annies Attic. Email me for details. Also have Avon collectables.

- Q:Are there any ground cover plants that are suitable for heavy clay soils?

- Yes, there are several ground cover plants that are suitable for heavy clay soils. Some examples include creeping thyme, creeping juniper, bugleweed, and periwinkle. These plants are known for their ability to tolerate and thrive in clay soils, making them ideal choices for providing ground cover in such conditions.

- Q:How does ground cover impact the growth of other plants?

- Ground cover can have a significant impact on the growth of other plants. It competes with them for resources such as sunlight, water, and nutrients, which can inhibit their growth. However, ground cover also provides benefits such as moisture retention, weed suppression, and erosion control, which can promote the growth of other plants by creating a more favorable growing environment. Ultimately, the specific impact of ground cover on other plants will depend on factors such as the type of ground cover, its density, and the specific needs of the plants involved.

- Q:Are nursery trays suitable for aquatic plants?

- No, nursery trays are not suitable for aquatic plants as they do not hold water and lack the necessary features for proper water circulation and root growth.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

HDPE Olive Garden Harvest Net Olive Tree Harvest

- Loading Port:

- Wenzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords