HDPE Membrane for Construction Use, High Quality

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 5000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

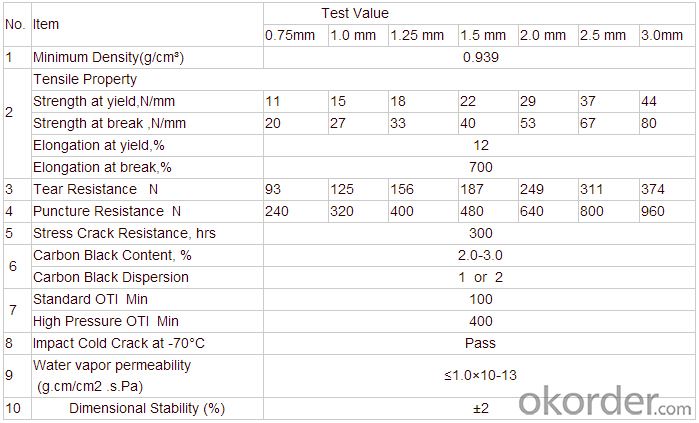

1,Specification of HDPE Geo membrane

1) Thickness : 0.15mm - 4.0mm.

2) Width : Within 8 m (1m-8m).

3) Length : 50m-100m/roll (as request).

4) Material : HDPE,( LDPE, LLDPE, PVC, EVA ).

5) Color : Black , white , red , blue , or as required.

6) Optional surface : Textued(one or two side) or smooth surface.

2,Feature of HDPE Geo membrane

Good mechanical properties, high tear strength, deformation and adaptable, puncture resistance, anti-aging, anti-ultraviolet-resistant, Anti oil and salt, pH, anti-corrosion, high temperature-resistant, non-toxic, long service life. water, drainage, seepage, the good effect of moisture, width, thickness of the full range of specifications and low cost, simple construction.

3, Application of HDPE Geo membrane

1) Environmental protection, sanitation (such as solid waste landfills, sewage treatment plants, power plants Chi-conditioning, industrial, hospital solid waste, etc.) .

2) Water (such as rivers, lakes and reservoirs of the anti-dam, plugging, reinforcement of the canal seepage, the vertical wall of the heart, slope protection, etc.).

3) Municipal Engineering (subway, on the ground floor of the building, planted roof, the roof garden of anti-seepage, sewage pipes lining, etc.).

4) Landscape (man-made lake, river, reservoir, golf courses reservoirs of the substrate, slope protection, green lawn of the waterproof moisture, etc.).

5) Petrochemical (chemical plants, oil refineries, gas storage tanks of the anti-chemical reaction tanks, sedimentation tanks of the lining, etc.).

6) Mining (washing and pool heap leaching, the ash-field, dissolved, precipitation, the yard, the tailings seepage substrates, etc.) .

4, Technical data of HDPE Geo membrane

6.FAQ

We have organized several common questions for our clients,may help you sincerely:

1>How about your company?

A manufacturer & supplier focuses on the production of construction materials, including but not limited to PP staple fiber, geotextile geo-grid, geo-bag etc. Customized product is also available based on your detailed requirements.

2>How long can we receive the product after purchase?

It takes about 1 to 4 weeks to finish the production based on the specific production schedual. Then it will depend on the shipping time from loading port to the destination port.

- Q:Can geotextiles be used in coastal dune stabilization projects?

- Yes, geotextiles can be used in coastal dune stabilization projects. Geotextiles are commonly used in such projects to create barriers that help prevent erosion, promote vegetation growth, and provide stabilization to the dune system. They can effectively control sand movement, prevent sand loss, and enhance the stability and resilience of coastal dunes.

- Q:Artificial lake geotextile practices

- Library and slope with a composite geomembrane all laying, I specialize in the production and construction of geotextile materials

- Q:How do geotextiles help in the construction of ponds and lakes?

- Geotextiles help in the construction of ponds and lakes by providing reinforcement, filtration, and erosion control. They act as a barrier between the soil and water, preventing soil erosion and promoting stability. Geotextiles also help in filtering out any fine particles or contaminants, ensuring clean and clear water. Additionally, they enhance the strength and durability of the pond or lake structure, increasing its longevity and resistance to wear and tear.

- Q:Artificial lake can not do geotextile waterproofing? What method can not do geotextile waterproof?

- Yes, with polyethylene polypropylene cloth is also OK

- Q:What are the design considerations for geotextile-reinforced pavement systems?

- Some design considerations for geotextile-reinforced pavement systems include choosing the appropriate geotextile material, determining the optimal placement and orientation of the geotextile, considering the load-bearing capacity and stability of the pavement system, assessing the potential for soil erosion and filtration, and evaluating the long-term durability and maintenance requirements of the system. Additionally, factors such as climate, traffic volume, and site-specific conditions should be taken into account during the design process.

- Q:What are the primary applications of geotextiles?

- Geotextiles have various primary applications that include erosion control, soil stabilization, drainage systems, road construction, and filtration.

- Q:What kind of geotextile is used to repair the road?

- Geotextile in the application of the road: a slope care, specifications in the 250-350g / m2 its role has the following three points: 1. filter when the water from the fine soil into the coarse soil layer, the use of polyester staple fiber Acupuncture geotextile good permeability and water permeability, so that water through, and effectively carrying soil particles, sand, small stone, etc., in order to maintain the stability of soil and water engineering. 2. Drain polyester staple fiber geotextile has a good water conductivity, it can form a drainage channel within the soil, the soil structure of excess liquid and gas efflux. 3. Protection of water flow on the soil erosion, the effective concentration of concentrated diffusion, transmission or decomposition, to prevent the soil by external forces and damage. Second, the foundation treatment, the main role is to strengthen. The use of polyester staple acupuncture geotextile to enhance the soil tensile strength and resistance to deformation, enhance the stability of the building structure to improve soil quality. Specifications not low 400g / m2. The main role is to use the polyester staple fiber geotextile with different physical properties (particle size, distribution, consistency and density, etc.) of the building materials (such as soil and sand, soil and concrete, etc.) ) To isolate. So that two or more materials are not lost, not mixed, to maintain the overall structure and function of the material, so that the building capacity to enhance the capacity. Specifications in the 150-400g / m2

- Q:How do geotextiles affect soil moisture retention?

- Geotextiles can positively impact soil moisture retention by acting as a barrier that prevents excessive evaporation of water from the soil surface. They create a physical barrier that reduces water loss through evaporation, thus helping to retain moisture within the soil. Additionally, geotextiles can also facilitate water infiltration and distribution, promoting better water retention and preventing runoff. Overall, geotextiles play a crucial role in enhancing soil moisture retention and improving water management in various applications, such as agriculture, landscaping, and erosion control.

- Q:How do geotextiles help with sediment control?

- Geotextiles help with sediment control by acting as a barrier to prevent the migration of sediment from construction sites or erosion-prone areas. They are placed in strategic locations to filter and separate sediment-laden water, allowing clean water to pass through while retaining the sediment. This helps to reduce erosion, maintain water quality, and protect nearby ecosystems.

- Q:300 grams of non-woven geotextile piercing strength is how much

- First of all, according to what you said 300g non-woven geotextile should be polyester staple fiber non-woven geotextile. Polyester staple fiber non - woven geotextile implementation of the national standard GB / T - 2008 standard. According to GB / T-2008 standard anti-puncture strength (standard is CBR burst strength) requirements, 300g national standard geotextile anti-piercing strength should be ≥ 1.5KN.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

HDPE Membrane for Construction Use, High Quality

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 5000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords