HDPE Geomembrane Liner for Landfills Capping

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Geomembrane Introduction

HDPE Geomembrane is a kind of waterproof material with basic raw material of high molecular polymer. Its material is HDPE.

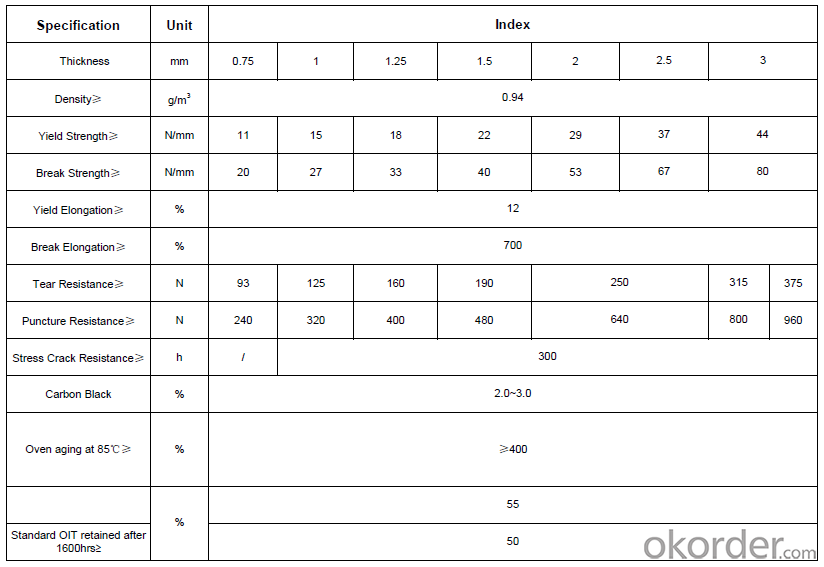

Geomembrane Specification

1)Material: LDPE

2)thickness:0.3mm~3.0mm

3)width:2m~7m

]]Product Package:

1. PE film inside, and Woven bag outside.

2. Packaged in container.

Product Application:

Product Application:

Landfill lining

Landfills capping

Water reservoirs

Pond-lining

Irrigation canals

Tunnels

Product Advantage

1.Some raw materials are produced by ourselves, or imported from overboard, so we could control the cost and quality to competitive in the market.

2. We have research team and laboratory, so we could research new products by ourselves and produce according client’s request.

3. There are more than fifty produce lines, so we could guarantee the delivery time.

4. We supply our products to many national projects in many countries, so our quality is stable and reliable.

5. If you have problem during your project when using our product, we could arrange our engineer to help.

FAQ:

- Q: What can we do for the special customer?

A: Provide custom made service with customer's drawing; We make sure to provide you with the best solutions for your individual case. Whether standard items or non-standard items.

- Q: What can we supply?

A: We provide high levels of communication from start to finish.

- Q: What is our advantage?

A: Top Cemented Carbide has extensive business experience, Fast delivery and high quality.

- Q:What is the piamater ceiling?

- The advantages of soft film ceiling: It is with a various styles and colors. It is mould proof, anti-bateria, and anti-aging with a good performance of insulation and waterproof. It can prevent the noise and heating, and save the cost of cooling and heating. It cannot be linked to dust and smoke proofing. It is non-toxic tasteless and enbironmental safety which is convenient to installation and disassembly. Disadvantages: The cleaning is difficult.

- Q:Is black HDPE geomembrane or dark green HDPE geomembrane better for landfill final cover?

- Black HDPE geomembrane is better.

- Q:Can geomembranes be used in chemical storage facilities?

- Yes, geomembranes can be used in chemical storage facilities. They are commonly employed as a lining system to prevent leaks, corrosion, and contamination of the surrounding environment. Geomembranes are resistant to various chemicals and offer excellent impermeability, making them suitable for containing hazardous substances in chemical storage facilities.

- Q:Why HDPE geomembrane(high density polyethylene geomembrane) is the most frequently used impermeable?material among artificial synthetic materials?

- The most widely used among landfill impermeable?materials is HDPE geomembrane, more than 90% of the world's landfills are using high-density polyethylene geomembrane as impermeable materials. Among HDPE geomembranes, the imported products are superior, because geomembrane :1 good chemical stability, landfill leachate will not pose a threat to them; 2 low permeability, underground?water and rainwater dialysate will not permeate through the liner, and methane gas will not come out; 3 carbon black in HDPE enhanced UV resistance, which is plasticizer-free, solving decomposition exposed to ultraviolet light. So HDPE geomembrane landfill is the preferred choice of impermeable materials, and is also the most commonly used.

- Q:What are the typical widths of geomembranes?

- The typical widths of geomembranes can range from 4 to 30 meters, depending on the specific application and project requirements.

- Q:Does the lower geotextile of composite geomembrane need seaming?

- In principle, it is needed, but mainly depending on site construction requirements.

- Q:What are the requirements for geomembranes used in aquaculture ponds?

- Geomembranes used in aquaculture ponds must meet certain requirements to ensure their effectiveness and durability. Firstly, they should have high impermeability to prevent water leakage and maintain optimal water levels in the pond. They should also possess excellent chemical resistance to withstand exposure to various water conditions and potential contaminants. Additionally, geomembranes must have sufficient strength and puncture resistance to withstand the weight of water, fish, and potential impacts from equipment or animals. UV resistance is also crucial to withstand prolonged exposure to sunlight. Finally, they should be easy to install and maintain to facilitate proper pond management.

- Q:What are the differences of seepage-proof geomembrane and polypropylene fiber impervious geotextile?

- Watercourse. The excellent environmental stress cracking resistance of seepage-proof geomembrane enables it to be used in large seepage-proof projects such as landscape lake, impounding reservoir and other projects, the anti-seepage effects are basically same: Toilet waterproofness seepage-proof geomembrane is made of high density polyethylene (HDPE) Tunnels: Reservoir, polypropylene fiber impervious geotextile is made of polypropylene fiber (PP). Polypropylene fiber impervious geotextile has a high friction coefficient which are often used in small buildings. These impermeable materials are both acid- and alkali-resisting.

- Q:Which one is better, electric heating film and carbon crystal?

- Carbon crystal, electrothermal?film, filament carbon fiber cables belong to carbon fiber heating. They also have the health care function of carbon fiber. But they differs in the service life and the nature of the insulation. I will analyze for you from the installation life and insulation; this is mainly caused by the different processing technology: Carbon fiber heating cable uses imported carbon fiber filament whose tensile strength is four times that of the same diameter steel, first coated by a layer of Teflon, king of plastic with temperature resistance up to 280 degrees, anti 4000 volts voltage (the material of 180 million \ ton), coated with 130 degree flame-retardant PVC. Electrothermal film is made of short wire carbon fiber or filament carbon fiber waste through crushing, grinding fineness of powder, again printing on plastic film with special glue mixed synthetic conductive coating, and covered with a layer of plastic film. Its insulation comes from plastic film both up and below, and its life depends on the degree of resistance to fracture of gel at high temperature. Carbon crystal is made of short filament carbon fiber, and filament carbon fiber cut into required waste, and spread on the insulating material according to the requirements of the uniform . Advantages and disadvantages of each are obvious.

- Q:What is geocell

- There are dozens of kinds of specifications about the specification of the geocell, it depends on the projects, and there are some requirements for the thickness, height and pitch of weld of the geocell.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

HDPE Geomembrane Liner for Landfills Capping

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords