HDPE Geomembrane for Pond-lining Construction

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

HDPE Geomembrane Introduction

HDPE Geomembrane is a kind of waterproof material with basic raw material of high molecular polymer. Its material is HDPE.

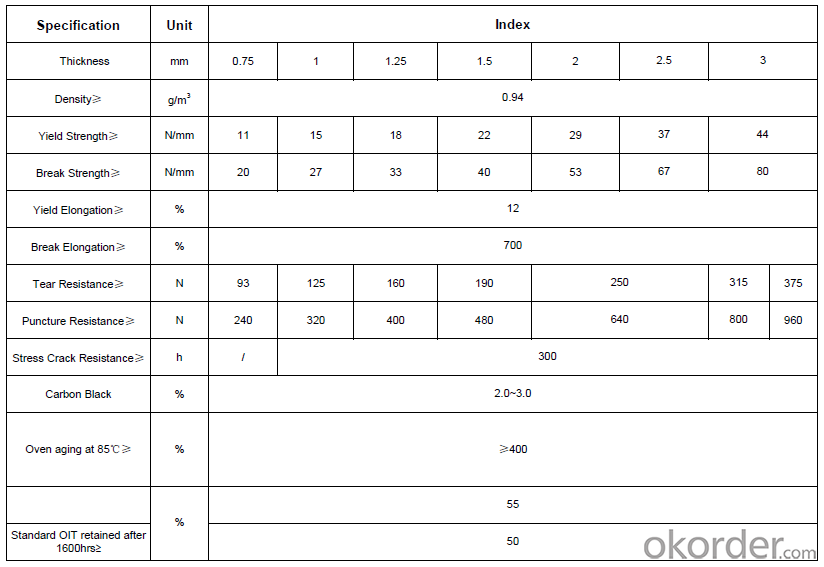

HDPE Geomembrane Specification

1)Material: HDPE

2)thickness:0.3mm~3.0mm

3)width:2m~7m

]]Product Package:

1. PE film inside, and Woven bag outside.

2. Packaged in container.

Product Application:

Product Application:

Landfill lining

Landfills capping

Water reservoirs

Pond-lining

Irrigation canals

Tunnels

Product Advantage

1.Some raw materials are produced by ourselves, or imported from overboard, so we could control the cost and quality to competitive in the market.

2. We have research team and laboratory, so we could research new products by ourselves and produce according client’s request.

3. There are more than fifty produce lines, so we could guarantee the delivery time.

4. We supply our products to many national projects in many countries, so our quality is stable and reliable.

5. If you have problem during your project when using our product, we could arrange our engineer to help.

FAQ:

- Q: What can we do for the special customer?

A: Provide custom made service with customer's drawing; We make sure to provide you with the best solutions for your individual case. Whether standard items or non-standard items.

- Q: What can we supply?

A: We provide high levels of communication from start to finish.

- Q: Can you send us samples?

A: Yes, we could arrange samples for free.

- Q:What are the advantages of using geomembranes in containment applications?

- There are several advantages of using geomembranes in containment applications. Firstly, geomembranes provide an impermeable barrier, preventing the leakage of liquids and gases, which is crucial in applications like waste management and environmental protection. Secondly, geomembranes are highly durable and resistant to environmental factors such as UV radiation, chemicals, and punctures, ensuring long-term performance and reliability. Thirdly, geomembranes are versatile and can be customized to fit the specific requirements of different containment applications. Additionally, they are relatively easy to install and maintain, resulting in cost and time savings. Lastly, geomembranes are an environmentally friendly solution as they help in preventing pollution and minimizing the impact on natural resources.

- Q:Geomembrane's features

- Width 6 meters wide composite film has high puncture-resistant strength and anti-friction coefficient, it can adapt to the ambient temperature range and has superior anti-drainage, it's applied in water?conservancy, chemical engineering, construction, transportation, iron, tunnels, waste disposal sites, etc.

- Q:The physical properties of HDPE geomembrane

- It has the following physical properties: ① excellent chemical resistance (corrosion resistance); ② outstanding resistance to stress cracking (ESCR); ③ the lowest permeability; ④ excellent UV resistance; ⑤ stable resistance to low temperature embrittlement;

- Q:How do geomembranes perform in seismic areas?

- Geomembranes perform well in seismic areas due to their flexible and durable nature. They are designed to withstand ground movement and vibrations caused by earthquakes, providing a reliable barrier against seepage and contamination. The high tensile strength and puncture resistance of geomembranes help them maintain their integrity even during seismic events, ensuring the safety and stability of containment systems in these areas.

- Q:How do geomembranes contribute to contaminated site remediation?

- Geomembranes are impermeable liners that are used in contaminated site remediation to prevent the spread and migration of contaminants. By acting as a barrier, geomembranes help contain and isolate the contaminants, minimizing their impact on surrounding soil, water, and air. Additionally, geomembranes can be used to create containment cells or caps, preventing further contamination and allowing for effective remediation activities such as excavation, treatment, or monitoring. Overall, geomembranes play a crucial role in the successful remediation of contaminated sites by providing an effective and reliable containment solution.

- Q:How to buy mulch applicator?

- How to choose mulch applicator: classification ? coated mulch applicator includes three parts: sizing, drying and hot pressing, having a broad scope of application and stable, reliable machinability. ? pre-coated mulch applicator does not have sizing and drying parts, small and easy to opearte, which is not only suitable for film mulching process for large quantities of printed matter, but also for film mulching process for small quantity and bulk printed matter of automatic desk office system. terminology ? single roll: There are only two couter pressing rubber rolls when mulching film. ? double rolls: There are four couter pressing rubber rolls when mulching film. ? single side: mulch film only on one surface of the product, usually the upper surface. ? double sides: muIch film on double sides of the product, usually the upper and lower surfaces. ? material receiving: For the label, protective film or 3M film and other products with release paper, tear off and recycle the release paper before mulching film. ? single transport: single side conveyor belt for rubber roll. ? double conveying: double sides conveyor belt for rubber roll. ? hot mulching film : Mounting special hot film in device heated to certain temperature (about 100-180 ℃) is called heat mount, divided into single sided hot mounting and double-sided hot mounting. With good light permeability, waterproofness, heat resistance and strong hardness, it is suitable for post production advertisings against the backdrop of light or in other occasions. ? cold mounting film mulching: Mounting the protection membrane on the surface of picture through cold pressing method is called cold mounting. divided into single and double side mounting. It is widely used in post production of advertising lamp box, engineering diagram and wedding photo, and in sheet metal industry (aluminum , iron, plastic, wood, steel, glass plate, etc.)

- Q:How do geomembranes contribute to erosion control in pipeline and utility corridor construction?

- Geomembranes contribute to erosion control in pipeline and utility corridor construction by providing a reliable barrier against soil erosion and water infiltration. These impermeable membranes are installed as liners or covers in areas prone to erosion, such as slopes and embankments, to prevent the loss of soil particles and the formation of gullies. By effectively containing soil and water, geomembranes help maintain the stability and integrity of the construction site, reducing the risk of damage to pipelines and utility corridors from erosion-related issues such as sedimentation or landslides.

- Q:Can geomembranes be used in decorative pond installations?

- Yes, geomembranes can be used in decorative pond installations. Geomembranes are often used as liners in ponds to prevent water leakage and provide a stable base for the pond. They can be hidden or covered with decorative elements such as rocks, plants, or other materials to create an aesthetically pleasing pond.

- Q:How do geomembranes contribute to erosion control in airport runway and taxiway construction?

- Geomembranes contribute to erosion control in airport runway and taxiway construction by acting as a protective barrier against the erosive forces of water. They prevent water from infiltrating the soil, which reduces the potential for soil erosion and the formation of ruts, potholes, or sinkholes. Additionally, geomembranes help in maintaining the stability and integrity of the runway and taxiway surfaces, ensuring safe and smooth operations for aircrafts.

- Q:Concrete and reinforced concrete construction program

- (1) template design, process design based on fair-faced concrete wall height of 13m, the length of 34.6m, a thickness of 0.5m, the design of the wall cicada seam topstitching requirements, using the wall template with a thickness of 12 mm, 1220 × 2440mm of Plywood covered were assembled, smooth bamboo has high strength, good toughness, smooth surface, wide-format, less patchwork, easy mold release characteristics. (2) On the basis of template installation concrete pouring is completed, the base elevation of the top of the concrete to be strictly controlled to ensure that the level on the wall template. Control template verticality is the key step, each template before fixing must be strictly controlled. Template vertical transport of scaffolding on the use of hand hoist, horizontal transport using manual handling. Templates in the handling process to the use of surface protection, to ensure that will not be damaged. To ensure that does not leak between the template and the template pulp, cracks in the template posted double-sided adhesive to ensure continuous tightly between two templates. Before template installation to wipe clean the surface evenly coated with a release agent. (3) the template of bolt and bolt arrangement using reinforced through the wall sleeve to add plug positioned to ensure that the position of the perforations through the wall tight to prevent leakage of plasma, wall bushing strength sufficient to locate the template spacing, resistance to new concrete pouring liquid pressure without generating the template gap is too large, plasma leakage phenomenon.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

HDPE Geomembrane for Pond-lining Construction

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords