HDPE Geomembrane For Lake Construction price

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description Of HDPE Geomembrane For Lake Construction:

HDPE geomembrane to plastic film as the backing material, seepage control and non-woven composite geotechnical seepage control material, its seepage control performance mainly depends on the seepage properties of plastic film.Seepage control of the application of plastic film, both at home and abroad are mainly polyvinyl chloride (PVC) and polyethylene (PE), EVA (ethylene/vinyl acetate copolymer), tunnel in the application and design using the ECB (ethylene vinyl acetate modified asphalt blending geomembrane), they are a kind of high polymer chemistry flexible material, the proportion of small, extensibility, adapt to the deformation capacity, high corrosion resistance, good low temperature resistance, frost resistance performance is good.The main mechanism is a plastic film impervious partition earth dam leakage channels, with its larger tensile strength and elongation under pressure and adapt to the deformation of dam body;And non-woven fabric is a kind of high polymer chemical short fiber material, through needle stick or hot forming, has high tensile strength and extensibility.

Main Features of HDPE Geomembrane For Lake Construction:

High quality 0.20mm to 2.50mm plasitc film producer high strength, low permeability, chemical corrosion resistance, ultraviolet & sun exposure resistance,oxidation resistance, weather resistance, antimicrobial, erosion resistance.

Roll width: 5.9m, maximum roll width is 8 meters

Loading quantity / 40HC: 42 rolls,5.8m*100m , 24360 m2

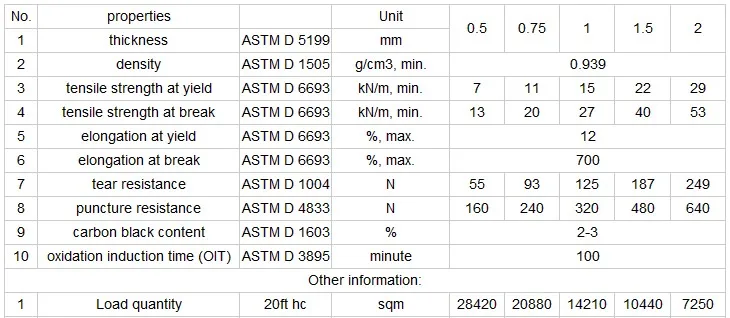

Specifications of HDPE Geomembrane For Lake Construction:

Applications of HDPE Geomembrane For Lake Construction:

1.Prevent leakage disposal in waste burying field or waste water or waste dregs disposing field,river bank,lake dam ,mine remainings ,reservior,tunnel,liquid storage ,pool(pit,mine)

2.Preventing leakage in subway ,basement,tunnel ,hole

3.Anti-solt leakage in roadbed and other groundtill

4.The plane direction laying of dam ,the vertical direction laying fou groundtill ,used in the construction fence and waste material field

5.Used in seawater or freshwater feed field

6.Used in groundtill of road,highway ,railway and waterproof layer of swelling clay and wet collapsed loess

Preventing leakage on rooftop.

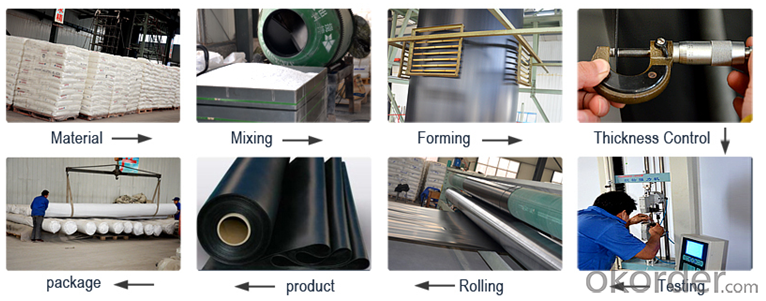

IMages of HDPE Geomembrane For Lake Construction:

FAQ:

1. Do you supply free samples for customers?

Yes,we will supply free samples for you.Please send your address for us.

2. How Many years experience do you have?

We have been exported to more than 20 countries in the past 15 years.

3. How long do we usually reply your request?

We always reply our customer within 24 hours.

- Q:What should be noticed when geomembrane is welding?

- The success of sewage treatment seepage control project depends on the quality of the geomembrane itself and the quality of its installation and construction.

- Q:How to choose glossy and matte geomembrane used in refuse landfill ?

- Do you refer to composite one? The more transparent the geotextile, the better. You'd better choose filament composite geotextile within 600g for wasteyard, setting at the edge of the slope and enclosure.

- Q:Where are construction geomembrane in ash dam?

- Geomembrane and other geotechnical materials are fixed with anchoring ditch in the middle of side slope. There are construction team and welding equipments.

- Q:What are the typical thicknesses of geomembranes?

- The typical thicknesses of geomembranes vary depending on the specific application, but they generally range from 0.5 to 2.5 millimeters.

- Q:Need we stick membrane on SLR camera?

- There is no need to stick membrane on the lens of the camera. The surface of lens itself has coating which can be corroded by the membrane stuck by ourselves. To protect the lens from scratching and touching, it's recommended to buy an ultraviolet filter with multilayer coating which can resist ultraviolet light and prevent the amount of light from dropping at the same time.

- Q:How do geomembranes contribute to the prevention of soil erosion in riverbank protection?

- Geomembranes contribute to the prevention of soil erosion in riverbank protection by providing a barrier between the soil and water, effectively reducing the impact of water flow on the soil. This barrier prevents water from directly eroding the soil and helps to maintain its stability. Additionally, geomembranes can also help in controlling the seepage of water through the soil, further reducing the risk of erosion and maintaining the integrity of riverbanks.

- Q:How to deal with the bubbles in the mobile phone film?

- If there are bubble in the mobile phone film, please use hard bank card or other cards to gently squeeze out the bubbles from intermediate network edge and surroundding. The process should be slowly, you don't be impatient, and pay attention to not crumble the big bubble. You shouls spend a relatively long time to scrape the bubble to the edge, and then squeeze out the bubble. At last, mobile phone film is perfect and flawless. if there is dust in the mobile phone film, it is more difficult to solve than the bubbles, this film is possibly destroyed , because it represents that you live in a dirty environment, the suspended solids in the air are too much, where is not suitable for sticking film.

- Q:What are the prospects of electrothermal?film?

- Electrothermal film has been in the market for at least ten years. Currently the biggest problem is the large power consumption, even if you can cover the electric charge,original home wire diameters restrict the use of high-power electrical appliances. Another problem is power attenuation, the other problem is breaker tripping caused by electric leakage.

- Q:Can geomembranes be used in sewage treatment plants?

- Yes, geomembranes can be used in sewage treatment plants. They are often employed as liners for containment ponds, lagoons, and wastewater treatment basins to prevent leakage and protect the surrounding environment from contamination. Geomembranes offer excellent chemical resistance, durability, and impermeability, making them suitable for various applications within sewage treatment plants.

- Q:what's the application of composite geo-membrane? What are its features? what's the variety of composite geotextile?

- It has large friction coefficient and good aging resistance performance, and is widely used in water?conservancy, metro/subway/underground. It can be adapt to the large range of environment temperature and has excellent water resistance. the composite geotextile, building, tunnel, high puncture strength, the anti-seepage project, such as the garbage disposal plant, traffic.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

HDPE Geomembrane For Lake Construction price

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords