HDPE Geomembrane Black or White for Pond

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 2000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description

HDPE geomembrane are made from High density polyethylene polymer by bolw film process .

Have Smooth surface , Textured surface , Anti-Skid suface

HDPE Geomembrane Main Function

Antiseepage and seperation

Geomembrane Property

1. Good flexibility

2. For service temperature range : -70℃ ~ +110℃

3. Corrosion resistance , aging resistance

4. Excellent environmental stress cracking resistance property

5. High tensile strength and elongation

HDPE Geomembrane Usage

Landfills , sewage or waste treatment seeage .

River bank , lake dam , dam , water dam and reservoir, channel , has liquid pool ( pit , mine )

Metro , basements and tunnels , tunnel seepage control lining Foundation and other foundation saline seepage

Embankment , upstream impervious blanket level , foundation vertical impermeable layer , cofferdam construction , waste disposal

Sea water , fresh water fish farm

Road , highway , railway foundation expansive soil and loess of the waterproof layer

Roof impervious

HDPE Geomembrane Specification

No. | Item | Test Value | |||||||||

0.75mm | 1.0 mm | 1.25 mm | 1.5 mm | 2.0 mm | 2.5 mm | 3.0mm | |||||

1 | Minimum Density(g/cm³) | 0.939 | |||||||||

2 | Tensile Property | ||||||||||

Yield Strength ,N/mm | 11 | 15 | 18 | 22 | 29 | 37 | 44 | ||||

Break Strength ,N/mm | 20 | 27 | 33 | 40 | 53 | 67 | 80 | ||||

Yield Elongation ,% | 12 | ||||||||||

Break Elongation ,% | 700 | ||||||||||

3 | Tear Resistance N | 93 | 125 | 156 | 187 | 249 | 311 | 374 | |||

4 | Puncture Resistance N | 240 | 320 | 400 | 480 | 640 | 800 | 960 | |||

5 | Stress Crack Resistance, hrs | 300 | |||||||||

6

| Carbon Black | ||||||||||

Carbon Black Content, % | 2.0-3.0 | ||||||||||

Carbon Black Dispersion | Carbon black dispersion(only near spherical agglomerates) for 10 different views 9 in categories 1 or 2 and 1 in category 3 | ||||||||||

7

| Oxidative induction time(OIT) | ||||||||||

Standard OTI Min | 100 | ||||||||||

High Pressure OTI Min | 400 | ||||||||||

8 | Oven aging at 85℃ | ||||||||||

Standard OIT-% retained after 90 days | 55 | ||||||||||

High pressure OIT-% retained after 90 days | 80 | ||||||||||

9 | UV Resistance | ||||||||||

Standard OIT retained after 1600 hrs | 50 | ||||||||||

High pressure OIT retained after 1600 hrs | 50 | ||||||||||

10 | Low tempreture impact brittle property at -70°C | Pass | |||||||||

11 | Water vapor permeability (g.cm/cm2 .s.Pa) | ≤1.0×10-13 | |||||||||

12 | Dimensional Stability (%) | ±2 | |||||||||

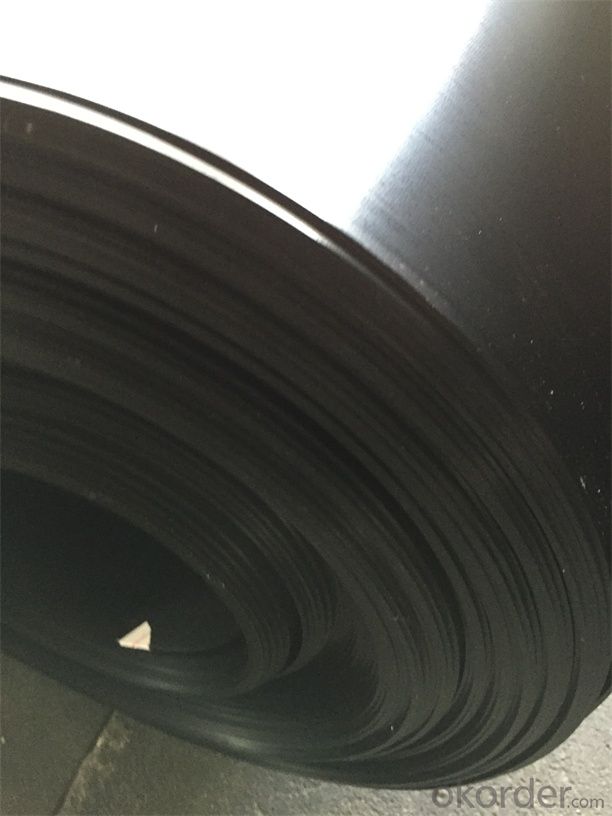

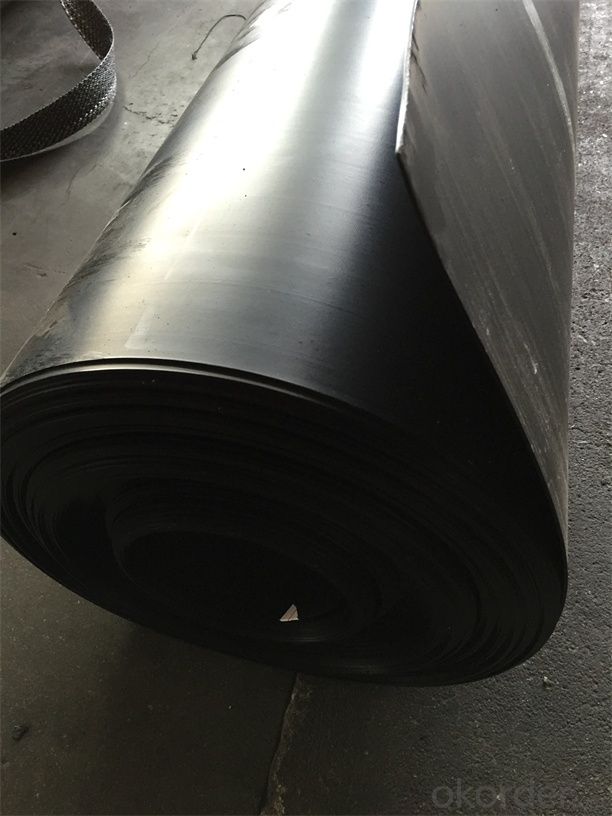

Gemembrane Show:

FAQ:

- Q1: Can you provide a sample for us?

A:Yes,We can send free samples,but customer need to pay the freight.

HDPE Geomembrane Price

- Q2: What is your minimum order quantity?

A:The minimum order quantity is 5000 ,but it is negotiable.

HDPE Geomembrane Price

- Q3:What is your payment terms?

A: T/T,Western Union,Paypal,L/C...

HDPE Geomembrane Price

- Q4:What is your delivery time?

A:Production time usually costs 2-20 days.

- Q:What's the method of adhering glass film to the window?

- Method of adhering glass film to the window: 1: The film is divided into two layers, of which the transparent one is called negative film, and the other with gum is called positive film. The film is very brittle, so please don't touch hard objects or fold it. Adhere the film indoors. 2: Wash the glass more than three times with pure water and a small amount of liquid detergent. 3: Before adhering the film, spray some water again to facilitate the positioning and movement of the film. 4: Stick the corners of solar?film with a small piece of tape, and gently pull open the transparent film layer. 5: Spray water uniformly on the gum of solar?film to prevent it from sticking impurities. 6: Scrape off the water evenly from the middle to both sides.

- Q:Can geomembranes be used in mining tailings management?

- Yes, geomembranes can be used in mining tailings management. They are often employed as liners or covers to contain and protect the tailings from leaking into the environment. Geomembranes provide an impermeable barrier, preventing the seepage of potentially harmful substances into the surrounding soil and water sources. They are also effective in reducing the risk of contamination and facilitating the proper management and disposal of mining tailings.

- Q:How do geomembranes contribute to the preservation of archaeological sites?

- Geomembranes contribute to the preservation of archaeological sites by acting as a protective barrier against moisture, contaminants, and erosion. They are used to cover and line excavation areas, preventing the infiltration of water that can damage artifacts and structures. Geomembranes also help to stabilize the soil and prevent erosion, ensuring the structural integrity of the site. Additionally, they can be used to create controlled environments for the storage and preservation of delicate artifacts, allowing for long-term conservation.

- Q:What are the installation requirements for geomembranes in landfill liners?

- The installation requirements for geomembranes in landfill liners typically include proper surface preparation, which involves removing vegetation, debris, and loose soil, and ensuring a smooth and uniform subgrade. Additionally, the liner must be carefully positioned and anchored to prevent shifting or wrinkling, and any seams or joints must be properly welded or sealed to maintain integrity. It is also important to consider factors such as slope, drainage, and compatibility with other liner components to ensure effective installation and long-term performance of the landfill liner system.

- Q:What are the codes for acceptance ofreinforced concrete project construction?

- Now there's a new revision. Notice on the issuance of the partial revision of national standards of Code for acceptance of constructional quality of concrete structures: Ministry of Housing and Urban-Rural Development Notice (No. 849): Partial revision of Code for acceptance of constructional quality of concrete structures GB50204-2002 is currently approved and come into force since August 1st, 2011. Wherein 5.2.1 and 5.2.2 1articles, as mandatory provisions must be strictly enforced. The original provisions of the amendment is abolished at the same time. Articles and article description of Code for acceptance of constructional quality of concrete structures GB50204-2002 partly revised by Ministry of Housing and Urban-Rural Development, PRC on December 20th, 2010. 5.2 dominant item of raw material 5.2.1 When rebars approach the site, sample some rebars for mechanical property and weight deviation test in accordance with the relevant standards of the state and the test results must meet the requirements of the relevant standards. Inspection quantity: depends on entering lot and sampling inspection plan of the product. Inspection method: check the factory certificate, the factory inspection report and approach re-inspection report.

- Q:what's the principle of composite geo-membrane protecting impervious barrier?

- according to the design requirements

- Q:Can geomembrane bond with glass fiber reinforced plastics?

- Yes.

- Q:What is the mechanism of capsule pressure gauge

- the instrument consists of the measuring system (including splice, ripple sylphon, etc.), transmission mechanism(including pull-bar mechanism, gear transmission mechanism), indicating parts (including pointer and dial) and shell (including watchcase, dial ring and the watch glass). Instrument working mechanism is based on a pressure measured medium, its free end produce the corresponding elastic deformation, and then the transmission gear transmit and enlarge the pointer fixed on the gear shaft which will be measured by value indicated on the dial. There have balancing controls which means you can easily adjust zero position.

- Q:Can geomembranes be used in floating solar panel installations?

- Yes, geomembranes can be used in floating solar panel installations. Geomembranes provide a waterproof barrier that helps to prevent water infiltration and potential damage to the solar panels. They can be used to create floating platforms or rafts for the solar panels, ensuring they remain buoyant and stable on the water surface. Additionally, geomembranes can also help with maintenance and cleaning of the solar panels by providing a stable surface for workers to walk on.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

HDPE Geomembrane Black or White for Pond

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 2000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords