High Strength Woven Geotextile for Road Construction Use

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

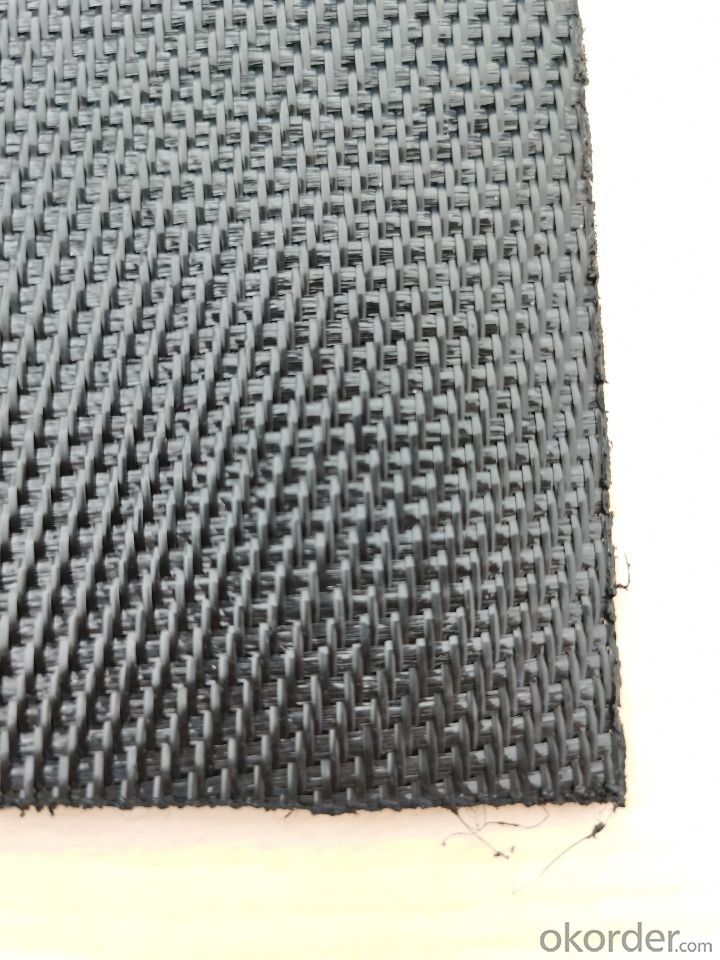

High Strength PP Woven Geotextile

1. Description of High Strength PP Woven Geotextile

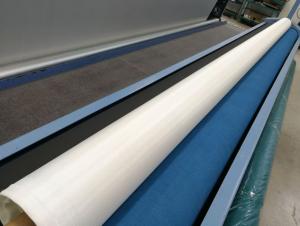

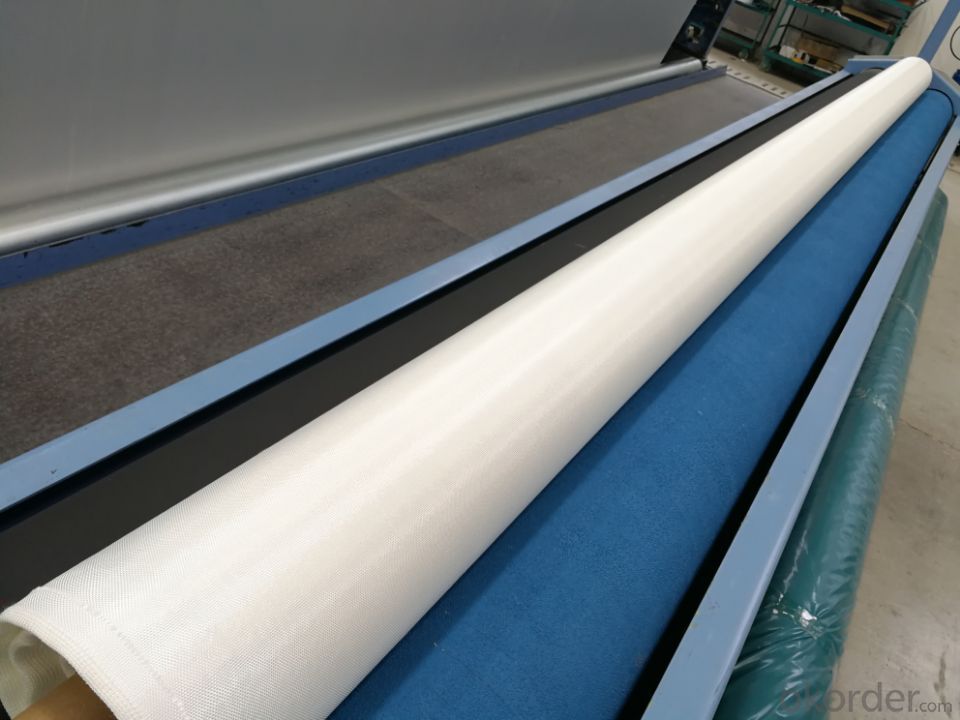

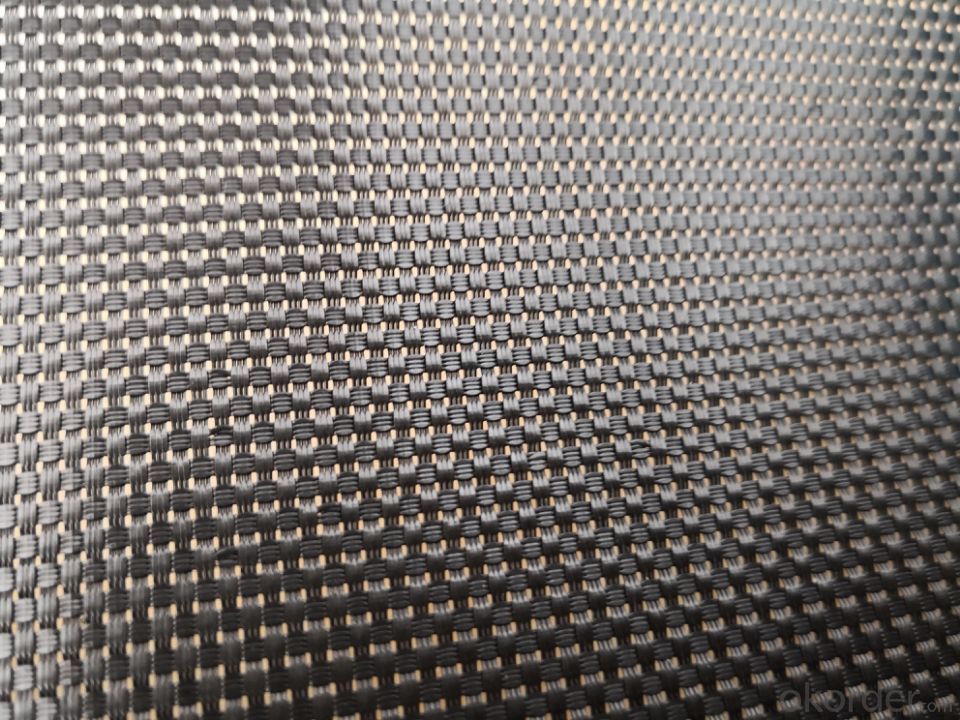

CMAX polypropylene woven geotextile is made from polypropylene flit yarn on circle weave machine, including circular loom and flat loom.

2. Specification of High Strength PP Woven Geotextile

Weight: 90gsm – 400gsm;

Width: 1m – 6m; Length: as clients’ required.

3. Technical Data Sheet of High Strength PP Woven Geotextile

Item | Unit | Index | ||||||

Unit Weight | g/m2 | 120 | 160 | 200 | 240 | 280 | 340 | 400 |

Breaking Strength in MD | KN/m | 20 | 30 | 40 | 50 | 60 | 80 | 100 |

Breaking Strength in CD | KN/m | 15 | 22 | 28 | 35 | 42 | 56 | 70 |

Elongation Rate | % | 25 | ||||||

Trapezoidal Tearing Strength | KN | 0.2 | 0.27 | 0.34 | 0.41 | 0.48 | 0.6 | 0.72 |

CBR Mullen Burst Strength | KN | 1.6 | 2.4 | 3.2 | 4.0 | 4.8 | 6.0 | 7.5 |

Vertical Permeability | Cm/s | 10^-1 ~10^-4 | ||||||

Sieve Size O90(O95) | Mm | 0.07 ~ 0.50 | ||||||

Variation | % | ±10 | ||||||

4. Property of High Strength PP Woven Geotextile:

1).Light weight, high strength, low elongation, easy to construct.

2).Reinforcement, separation, drainage and filtration, fencing function.

5. Application of High Strength PP Woven Geotextile

Railways, highways, sport fields, earthwork projects, tunnels, coal mines, walls and slopes, environmental protection and so on.

.

High Strength PET Woven Geotextile

1. Description of PET Woven Geotextile

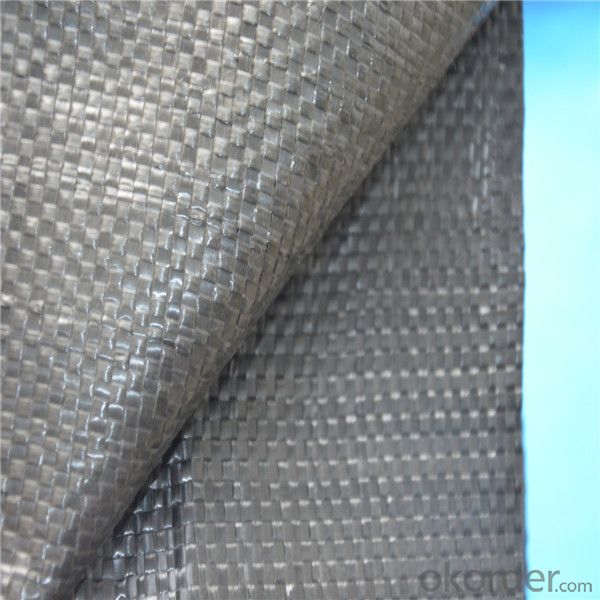

CMAX filament woven geotextile is made from polypropylene, high strength industrial synthetic fiber as the raw material, made through weaving technology.

2. Specification of PET Woven Geotextile

Breaking strength in MD(KN/m): 35, 50, 65, 80, 100, 120, 140, 160, 180, 200, 250;

Width: 1m – 6m.

3. Technical Data Sheet of PET Woven Geotextile

Item | Specification | ||||||||||

Material | Polyester | ||||||||||

MD(KN/m) | 35 | 50 | 65 | 80 | 100 | 120 | 140 | 160 | 180 | 200 | 250 |

CD(KN/m) | 35 | 50 | 65 | 80 | 100 | 120 | 140 | 160 | 180 | 200 | 250 |

Elongation at Break | MD=35; CD=30 | ||||||||||

Width Variation, % | ±0.1 | ||||||||||

CBR Mullen Burst Strength, KN | 2.0 | 4.0 | 6.0 | 8.0 | 10.5 | 13 | 15.5 | 18 | 20.5 | 23 | 28 |

Sieve Size O90(O95) mm | 0.07 ~ 0.50 | ||||||||||

Tearing Strength, KN | 0.5 | 00.8 | 1.1 | 1.3 | 1.5 | 1.7 | 1.9 | 2.1 | 2.3 | 2.5 | 3.0 |

Weight, g/m2 | 140 | 2200 | 260 | 320 | 390 | 450 | 530 | 600 | 680 | 760 | 950 |

Property of PET Woven Geotextile:

1) High strength, low deformation.

2) Durability: steady property, not easy to resolved, air slaked and can keep the original property long term.

3) Anti-erosion: anti-acid, anti-alkali, resists insects and mould.

4) Permeability: could control the sieve size to retain certain permeability.

Application of PET Woven Geotextile

It is widely used in river, coast, harbor, highway,railway, wharf, tunnel, bridge and other geotechnical engineering.

It could meet all kinds of geotechnical projects needs such as filtration, separation, reinforcement, protection and so on.

FAQ:

Questions and Answers:

Q: Can you accept sample order?

A: Yes, we accept samples with little and reasonable charge.

Q: What is your MOQ?

A: Normally, 5000 m2 per order.

Q: What is your delivery time? Can we short it in 7 days or less?

A: 7 days for sample, 20-25 days for mass production.

Q:How about your quality?

A: Try a small order, you will have your own judgment!

- Q:Can earthwork products be used for waterway management?

- Yes, earthwork products can be used for waterway management. They are commonly used for erosion control, stabilizing banks, constructing dams, creating berms, and shaping channels. These products, such as geotextiles, geogrids, and geomats, help manage waterways by preventing soil erosion, promoting vegetation growth, and improving the overall stability and functionality of the watercourse.

- Q:Why study civil engineering materials?

- Understand the construction is mainly used to what material, not the time you do not know anything.

- Q:These two are learning what courses, engage in what industry, employment wages, the development of space, the need for expertise, and so on and so on. Which is better? I 3, reported to build large

- Civil Engineering Professional Overview: The professional learning engineering mechanics, fluid mechanics, geotechnical and municipal engineering disciplines of the basic theory and basic knowledge. Mainly engaged in railway, highway, airport and other projects and housing, bridges, tunnels, underground engineering planning, surveying, design, construction, conservation and other technical work and research work of high-level engineering talent. Graduates in the university, design departments and research institutes teaching, design, research work, but also in the management, operation, construction, real estate development and other departments engaged in technical work.

- Q:How do earthwork products contribute to dust control in construction sites?

- Earthwork products such as gravel, crushed stone, and soil stabilization materials play a crucial role in dust control on construction sites. These materials are used to create stable surfaces that prevent soil erosion and minimize dust generation. By providing a solid foundation, earthwork products reduce the amount of loose soil and dust that can be easily stirred up by wind or construction activities. Additionally, these products can be mixed with water or applied as surface treatments to further suppress dust particles, creating a safer and healthier environment for workers and surrounding communities.

- Q:Can earthwork products be used for constructing wildlife habitats?

- Yes, earthwork products can be used for constructing wildlife habitats. Earthwork products such as soil, gravel, and rocks can be used to create various features in wildlife habitats, including mounds, berms, ponds, and burrows. These features can provide shelter, nesting sites, and foraging opportunities for different species of wildlife. Additionally, earthwork products can be used to shape the landscape, creating diverse topography that supports a wide range of habitats and ecosystems for wildlife.

- Q:University opened this course, you can learn for more than a month, do not know what the teacher is talking about, he is the theory let us know the knowledge or this thing can be used after the life, in addition to cement there are other

- For example, you do the construction of the house, with the cement, sand, stone, steel, etc., have strict quality requirements. Such as the existence of poor cement stability problems in the project is very easy to work accident; there are many varieties of cement, in many places some cement varieties can not be used, with the wrong will be a project accident, resulting in economic losses. Another cement in the plaster is not the higher the strength the better, with the minimum 32.5 strength is enough, so sometimes more money is not very applicable.

- Q:What are the different types of geosynthetic tubes used in riverbank protection?

- There are several types of geosynthetic tubes used in riverbank protection, including geotextile tubes, geogrid tubes, and geocell tubes. Geotextile tubes are made of high-strength woven or non-woven geotextile fabric and are filled with sand or soil to provide erosion control and stabilize riverbanks. Geogrid tubes, on the other hand, are constructed using geogrid materials and are typically filled with aggregate or other materials to reinforce the riverbank. Geocell tubes consist of interconnected cells made of geosynthetic materials and are filled with soil or other materials to create a porous structure that prevents erosion and promotes vegetation growth. These different types of geosynthetic tubes offer various solutions for riverbank protection depending on the specific needs and conditions of the site.

- Q:How can geopipes be used in underground utility tunnel projects?

- Geopipes can be used in underground utility tunnel projects to facilitate the efficient and effective management of various utilities such as water, sewage, gas, and telecommunications. These pipes can be installed to create a well-structured network, ensuring the safe and reliable transportation of utilities throughout the tunnel system. Additionally, geopipes offer resistance against corrosion, leakage, and ground settlement, minimizing the risk of disruptions or damages to the utilities. Overall, geopipes play a vital role in enhancing the functionality and longevity of underground utility tunnels.

- Q:The Relationship between Material Development and Civil Development

- The material is too important for civil engineering. Many need this knowledge

- Q:How do geosynthetic clay liners work in containment projects?

- Geosynthetic clay liners (GCLs) are used in containment projects to provide a barrier against the migration of fluids or gases. GCLs consist of a layer of bentonite clay sandwiched between two geotextile layers. When hydrated, the bentonite clay swells, creating a low permeability barrier that prevents the passage of contaminants. The geotextile layers provide mechanical strength and protect the clay from damage. Overall, GCLs function by combining the hydraulic properties of the clay with the geotextile layers, ensuring effective containment in various engineering applications.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

High Strength Woven Geotextile for Road Construction Use

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords